Sound insulation mortar, sound insulation floor slab, building and construction method of sound insulation floor slab

A construction method and sound insulation technology, which is applied in the construction of buildings and sound insulation floors, sound insulation mortar, and sound insulation floor slabs. It can solve the problems of reduced effective net height of indoor space, serious indoor space occupation, and increased floor weight. Achieve the effects of reducing self-weight, improving construction economy, and simplifying the construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

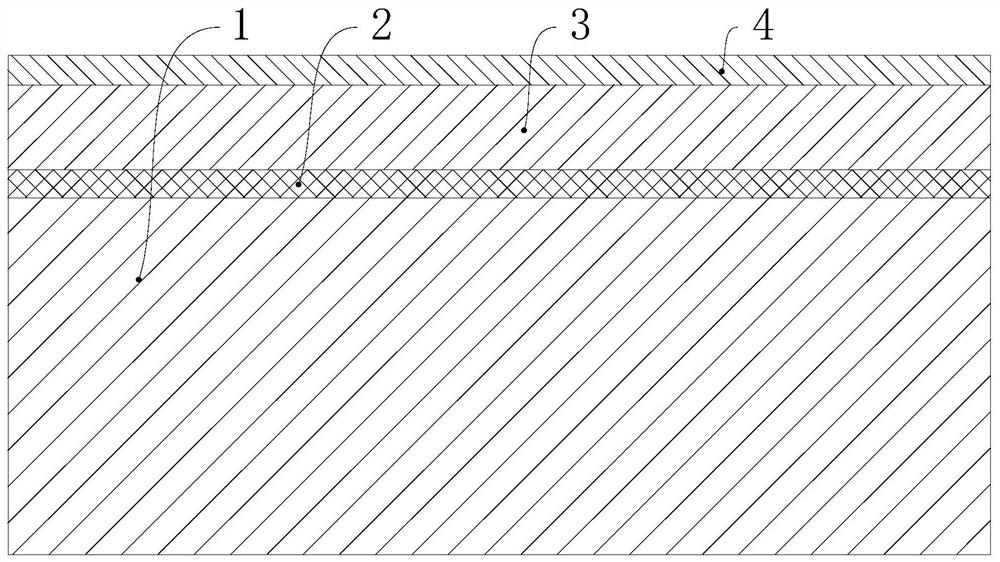

[0027] The buildings of this embodiment are commercial buildings, such as residential buildings, office buildings, etc., and the floor slabs of the buildings of this embodiment adopt the soundproof floor slabs of this embodiment, please refer to figure 1 , the sound insulation floor of the present embodiment comprises a base layer 1 and a sound insulation layer 2, and the sound insulation layer 2 is laid on the upper side of the base layer 1, wherein the base layer 1 is a reinforced concrete structure with a thickness of 100 mm, and the sound insulation layer 2 is made of this The sound insulation mortar of the embodiment is dried and formed.

[0028] The sound insulation mortar of the present embodiment is formed by mixing functional raw materials and water. By weight percentage, the functional raw materials include: 29% cement, 42% elastic sound insulation particles, 6% sand, 11% vermiculite, 4% Mica powder, and 8% construction adhesive.

[0029] The weight ratio of the fun...

Embodiment 2

[0049] In the sound insulation mortar of the present embodiment, the functional raw materials include: 33% cement, 34% elastic sound insulation particles, 4% sand, 13% vermiculite, 6% mica powder, and 10% by weight percentage. % of construction adhesives.

[0050] The particle size of the elastic sound-insulating particles in this embodiment is 0.5 mm to 2 mm.

[0051] The weight ratio of functional raw materials and water mixed to form the sound insulation mortar of this embodiment is 2.1:1.

[0052] The rest of this embodiment is the same as Embodiment 1.

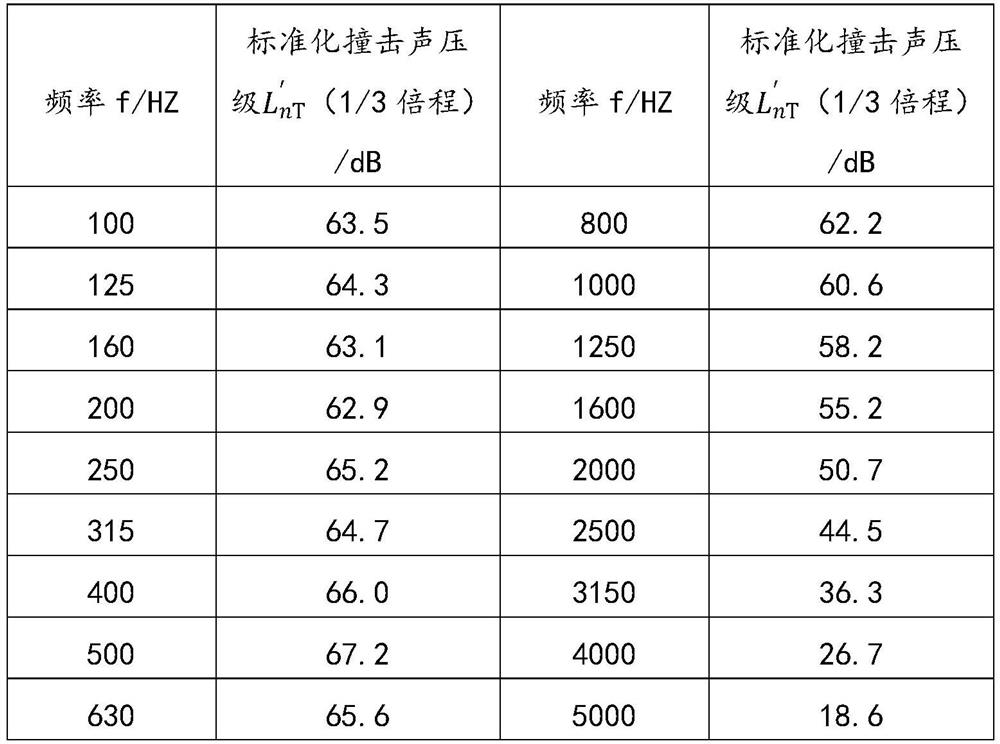

[0053] In order to verify the sound insulation effect of the sound insulation floor of this embodiment, according to "Acoustic Building and Building Components Sound Insulation Measurement Part 7: On-site Measurement of Floor Impact Sound Insulation" GB / T 19889.7-2005 and "Building Sound Insulation Evaluation Standard" GB / T50121-2005 carried out impact sound test experiment 2 on the sound insulation floor of this embodi...

Embodiment 3

[0059] In the sound insulation mortar of the present embodiment, the functional raw materials include: 33% cement, 34% elastic sound insulation particles, 4% sand, 13% vermiculite, 6% mica powder, and 10% by weight percentage. % of construction adhesives.

[0060] The particle size of the elastic sound-insulating particles in this embodiment is 0.5 mm to 2 mm.

[0061] The weight ratio of functional raw materials and water mixed to form the sound insulation mortar of this embodiment is 2.5:1.

[0062] The thickness of the sound insulation layer 2 in this embodiment is 6 mm.

[0063] The rest of this embodiment is the same as Embodiment 1.

[0064] In order to verify the sound insulation effect of the sound insulation floor of this embodiment, according to "Acoustic Building and Building Components Sound Insulation Measurement Part 7: On-site Measurement of Floor Impact Sound Insulation" GB / T 19889.7-2005 and "Building Sound Insulation Evaluation Standard" GB / T50121-2005 car...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com