A filter stick online sampling device

A sampling device and filter rod technology, applied in the field of filter rod online sampling device, can solve the problems of product quality and equipment efficiency, difficulty in meeting fine management requirements, loss of raw and auxiliary materials, etc., to improve quality and save equipment debugging. time, the effect of reducing work intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to more clearly and specifically illustrate the purpose and technical solution of the present invention, the specific details of the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, but not to limit the present invention.

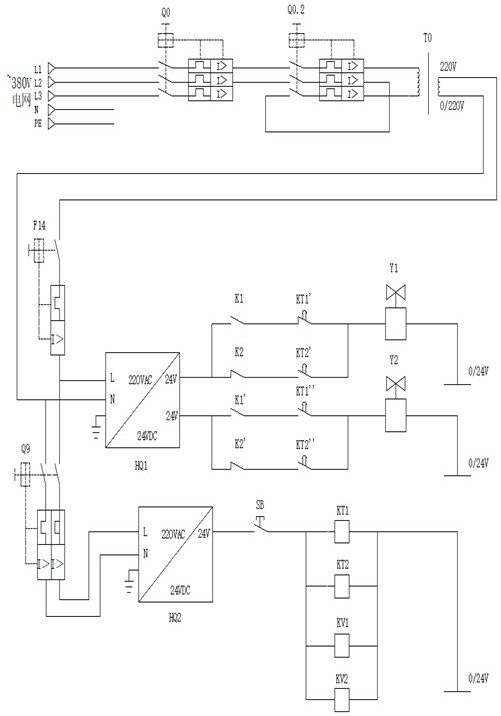

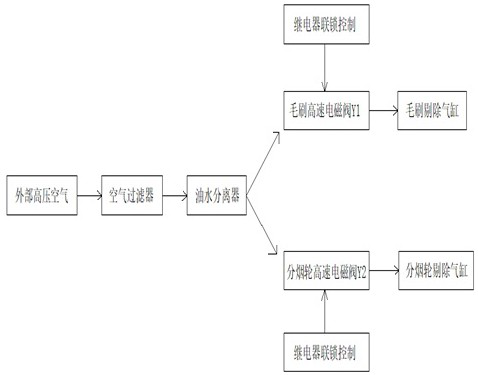

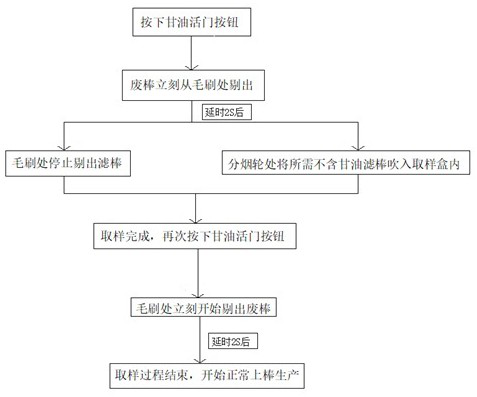

[0015] like figure 1 , 2 As shown, this embodiment provides an online filter rod sampling device, including an electric control system, an air filter, an oil-water separator, a static eliminator, and a sample collection box; the electric control system includes a push button switch SB with self-locking control , 24V switching power supply HQ1, HQ2, circuit breaker Q0, Q0.2, Q9, fuse F14, small transformer T0, smoke wheel high-speed solenoid valve Y2, brush high-speed solenoid valve Y1, 24V DC relay KV1, KV2, 24V DC Power-on delay relay KT1, 24V DC power-off de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com