Differential pressure anti-gravity mold-filling solidification device under action of external field and process method thereof

A gravity and process technology, applied in the field of low pressure casting, can solve the problems of inability to completely stir and remove impurities and gases, and achieve the effects of low porosity of castings, enhanced nucleation and dissociation, and uniform distribution of solutes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

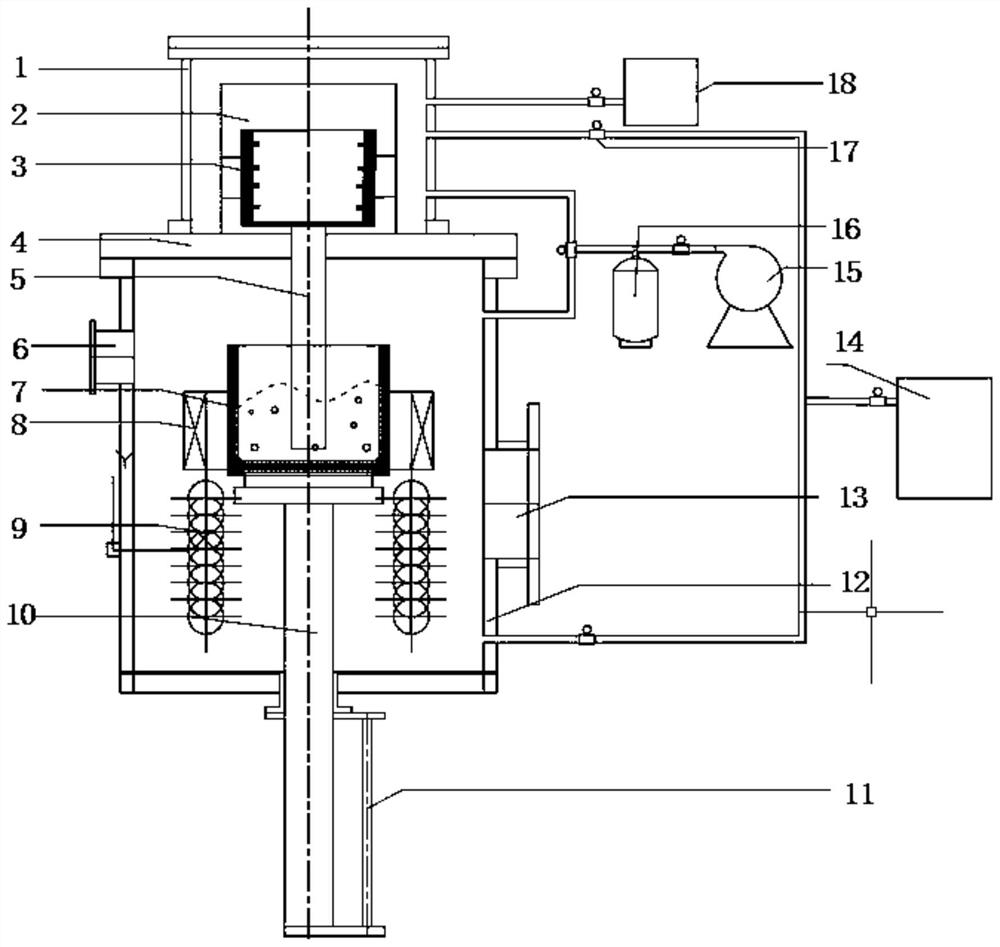

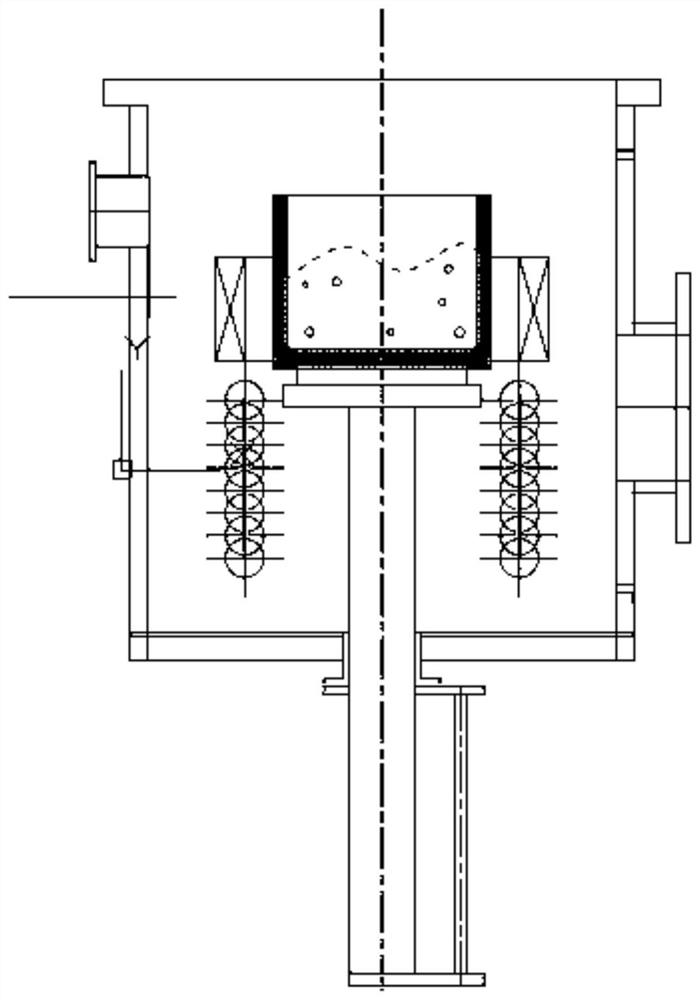

[0048] 1. Put ZL114A aluminum alloy raw materials or pure aluminum and intermediate alloys such as Al-Si and Al-Mg into the melting crucible 7 after drying and removing surface impurities, and start the induction melting device 9 to melt the raw materials at 700-710°C liquid, and then use the hydraulic lifting platform 10 to lift the crucible to such as figure 2 In the position shown, the modification agent is used for modification, and the high-purity argon with a purity greater than 99.99% is used for degassing and then slag removal;

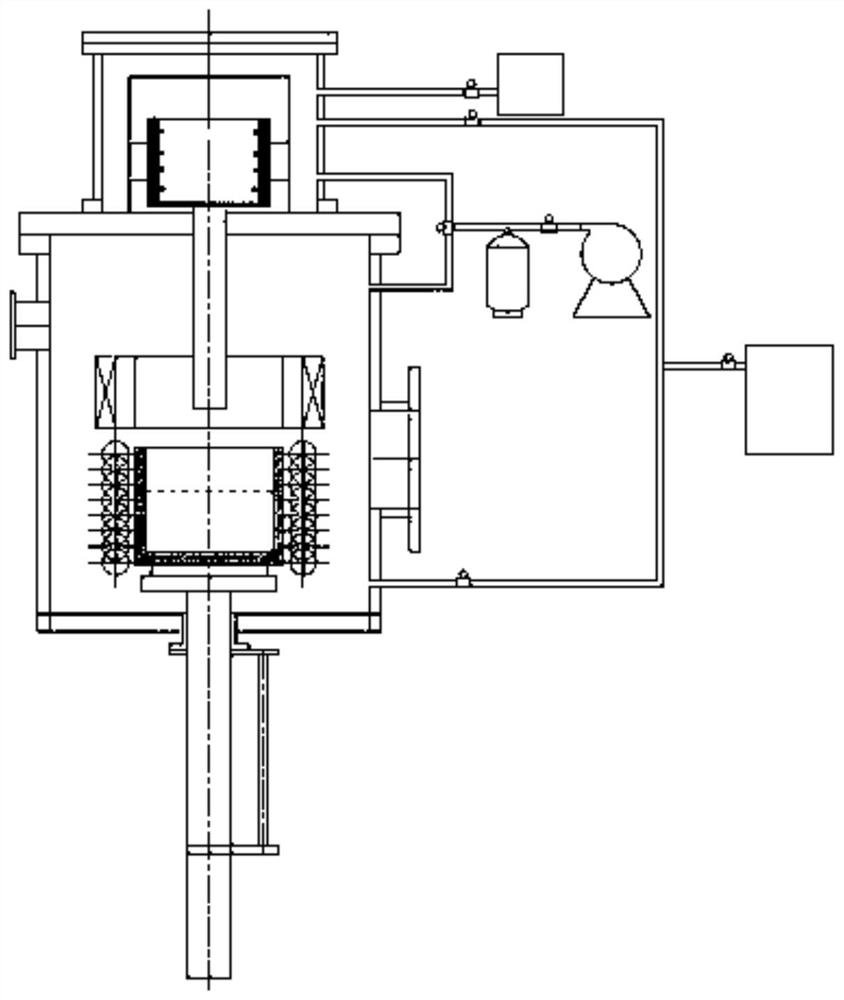

[0049] 2. After removing slag, use the hydraulic lifting platform 10 to lower the melting crucible 7 to the induction heating device, such as image 3 As shown, the middle plate 4 is closed, and after the infusion tube 5, the casting mold 2 and the upper cavity 1 are installed, the upper cavity 1 and the lower cavity 12 are separated by the vacuum tank 16 Simultaneously vacuumize 10-20Pa;

[0050] 3. Start the induction heating device to ra...

Embodiment 2

[0056] 1. Put ZL205A aluminum alloy raw materials or intermediate alloys such as pure aluminum and Al-Cu into the melting crucible 7 after drying and removing surface impurities, start the induction melting device 9 to melt the raw materials into a liquid at 700-715°C, and then use The hydraulic lifting platform 10 lifts the melting crucible 7 to such as figure 2 In the position shown, the modification agent is used for modification, and the high-purity argon with a purity greater than 99.99% is used for degassing and then slag removal;

[0057] 2. After removing slag, use the hydraulic lifting platform 10 to lower the melting crucible 7 to the induction melting device 9, close the middle plate 4, install the infusion tube 5, the casting mold 2 and the After the upper cavity 1, use the vacuum tank 16 to simultaneously evacuate the upper cavity 1 and the lower cavity 12 by 10-30Pa;

[0058] 3. Start the induction smelting device 9 to raise the molten metal to a predetermined ...

Embodiment 3

[0063] 1. Put ZL104A or A357 aluminum alloy raw materials or pure aluminum and intermediate alloys such as Al-Si and Al-Mg into the melting crucible 7 after drying and removing surface impurities, and start the induction melting device 9 to melt the raw materials into 710~ 720°C liquid, and then use the hydraulic lifting platform 10 to lift the melting crucible 7 to such as figure 2 In the position shown, the modification agent is used for modification, and the high-purity argon with a purity greater than 99.99% is used for degassing and then slag removal;

[0064]2. After removing slag, use the hydraulic lifting platform 10 to lower the melting crucible 7 to the induction heating device, such as image 3 As shown, the middle plate 4 is closed, and after the infusion tube 5, the casting mold 2 and the upper cavity 1 are installed, the upper cavity 1 and the lower cavity 12 are separated by the vacuum tank 16 Simultaneously vacuum 20-40Pa;

[0065] 3. Start the induction sme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com