Drying device for producing dried flowers

A drying device and drying flower technology, applied in drying, drying machine, drying gas arrangement, etc., can solve the problems of increasing the production cost of dried flowers, failure to recycle, uneven heating, etc., to improve the heating and drying effect, Reduce energy consumption and improve heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

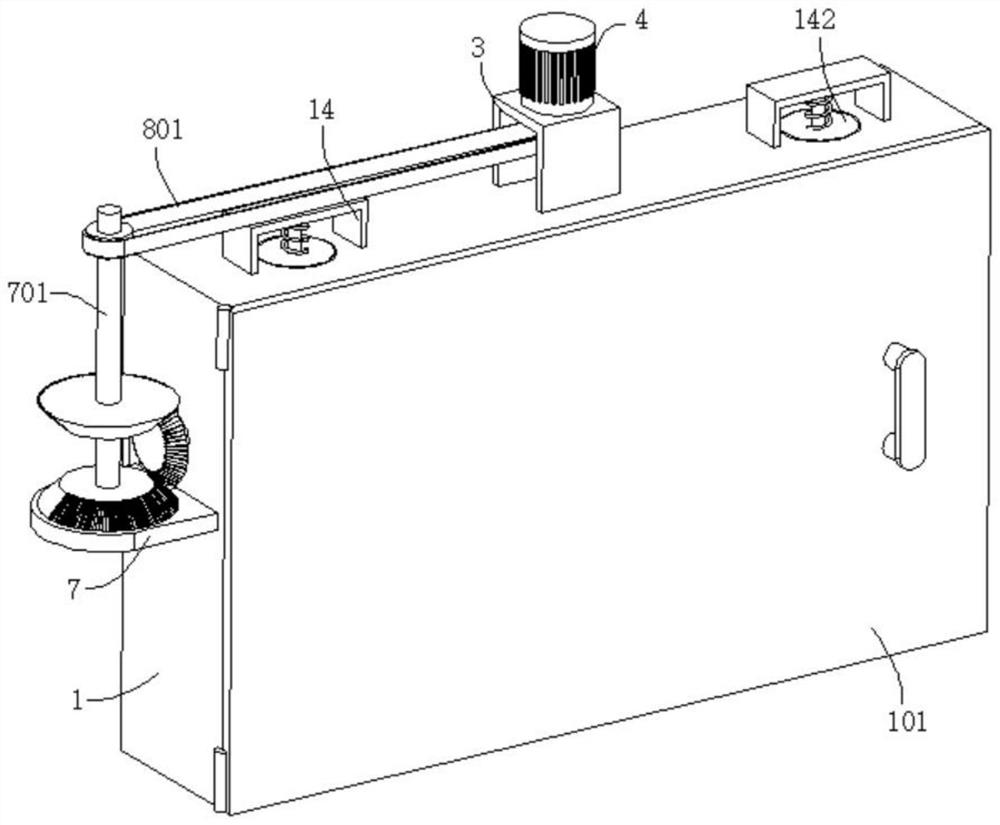

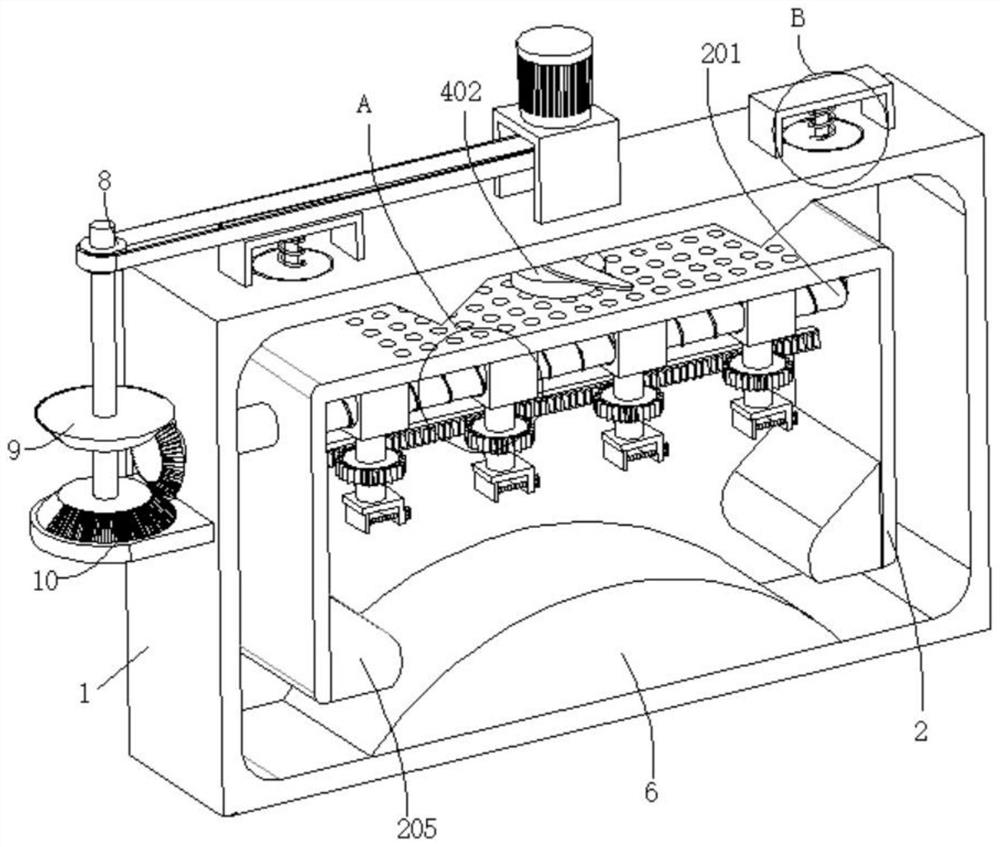

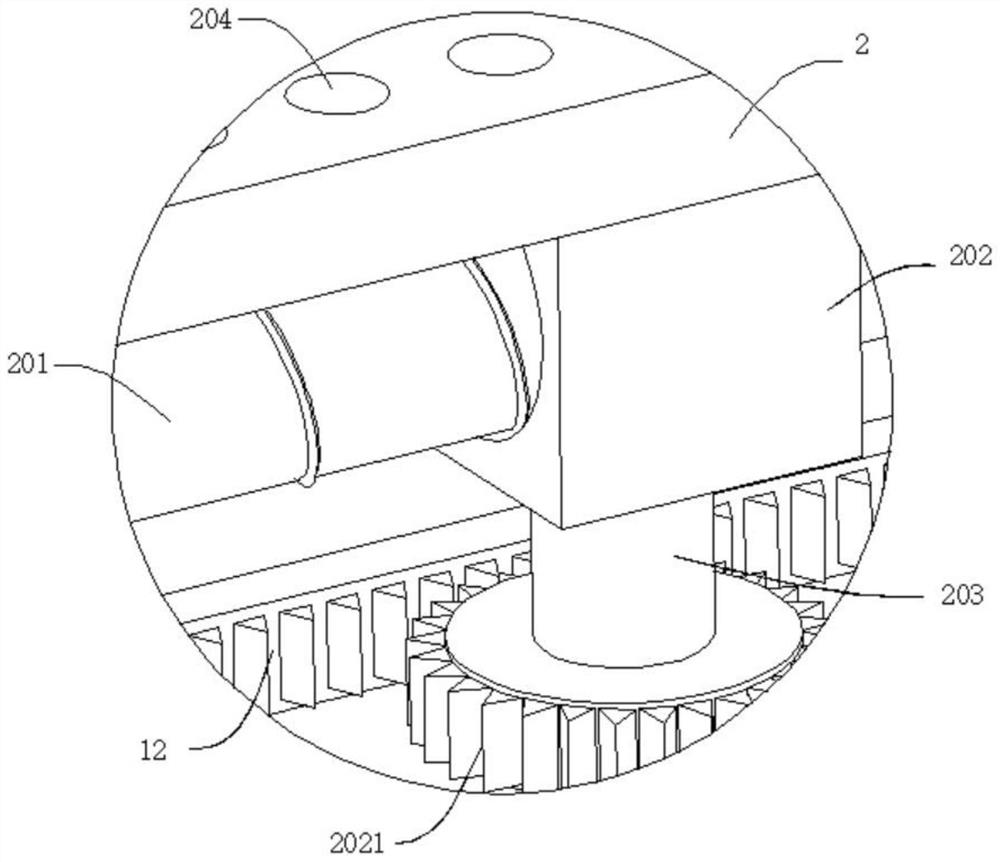

[0034] refer to figure 1 , figure 2 , image 3 and Figure 5 , a drying device for producing dried flowers, comprising a box body 1, the outer wall of the box body 1 is connected with a box door 101 through a hinge, the inner wall of the box body 1 is fixedly connected with a casing 2, and the top of the casing 2 is dug with evenly distributed The circulation hole 204, the inner wall of the housing 2 is connected with a threaded rod 201, the outer wall of the threaded rod 201 is threaded with a moving sleeve 202, the bottom wall of the moving sleeve 202 is connected with a connecting rod 203, and the end of the connecting rod 203 is far away from the moving sleeve 202 The clamping assembly is connected, the top of the box body 1 is connected to the support base 3, the outer wall of the support base 3 is connected to the motor 4, the output end of the motor 4 is connected to the rotating shaft, and the end of the rotating shaft away from the motor 4 passes through the suppor...

Embodiment 2

[0038] refer to figure 1 , figure 2 , image 3 and Figure 5 , a drying device for producing dried flowers, comprising a box body 1, the outer wall of the box body 1 is connected with a box door 101 through a hinge, the inner wall of the box body 1 is fixedly connected with a casing 2, and the top of the casing 2 is dug with evenly distributed The circulation hole 204, the inner wall of the housing 2 is connected with a threaded rod 201, the outer wall of the threaded rod 201 is threaded with a moving sleeve 202, the bottom wall of the moving sleeve 202 is connected with a connecting rod 203, and the end of the connecting rod 203 is far away from the moving sleeve 202 The clamping assembly is connected, the top of the box body 1 is connected to the support base 3, the outer wall of the support base 3 is connected to the motor 4, the output end of the motor 4 is connected to the rotating shaft, and the end of the rotating shaft away from the motor 4 passes through the suppor...

Embodiment 3

[0043] refer to figure 1 , figure 2 , image 3 , Figure 5 and Figure 6 , a drying device for producing dried flowers, which is basically the same as that of Embodiment 2, furthermore, the outer wall of the box body 1 is connected with a support plate 7, and the support plate 7 is connected with a rotating rod 701 through the first bearing in rotation, and the rotating rod 701 and the outer wall of the rotating shaft 401 are connected with a matching synchronous wheel 8 , and a synchronous belt 801 is connected between the two synchronous wheels 8 .

[0044] Two first bevel gears 9 and a second bevel gear 10 are respectively connected to the outer wall of the rotating rod 701, the second bevel gear 10 is placed below the first bevel gear 9, and both the first bevel gear 9 and the second bevel gear 10 are meshed A third bevel gear 11 is connected, and the third bevel gear 11 is connected with the threaded rod 201 .

[0045] Both the first bevel gear 9 and the second beve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com