Grating structure writing method of short-wave range reflective volume grating

A grating structure and reflective technology, which is applied in the field of diffractive optical element preparation, can solve problems such as difficulties in short-wave preparation, and achieve the effects of ensuring stability, low processing cost, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

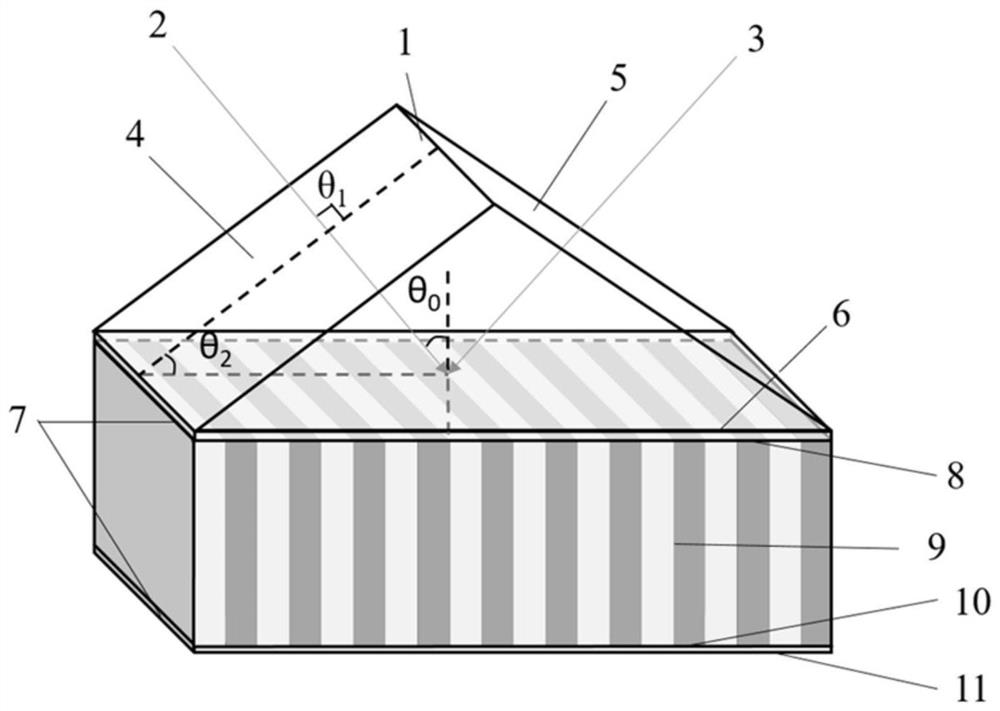

[0037] Embodiment 1: The preparation wavelength of the prism coupling exposure method is 450±0.5nm reflective volume grating, the specific steps are as follows:

[0038] (1) The exposure wavelength λ of the provided parallel UV light 2,3 曝 = 325nm.

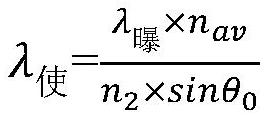

[0039] (2) The incident surface 8 and the outgoing surface 10 of the PTR glass 9 to be exposed are polished, and the refractive index of the PTR glass 9 is n under the exposure wavelength 325nm 1 =1.528, the refractive index n at the grating wavelength of 450nm av =1.512

[0040] (3) Calculate the exposure angle θ 0 is 45.6°. Choose base angle θ 2 isosceles prism 1 of 45.6°, its refractive index is n 2=1.528, the two isosceles surfaces 4 and 5 of the triangular prism 1 are plated with a 325nm ultraviolet anti-reflection coating to increase the transmittance of 325nm.

[0041] (3) Use matching liquid 7 to bond the bottom edge 6 of the triangular prism with the incident surface 8 of the PTR glass to prevent light reflection a...

Embodiment 2

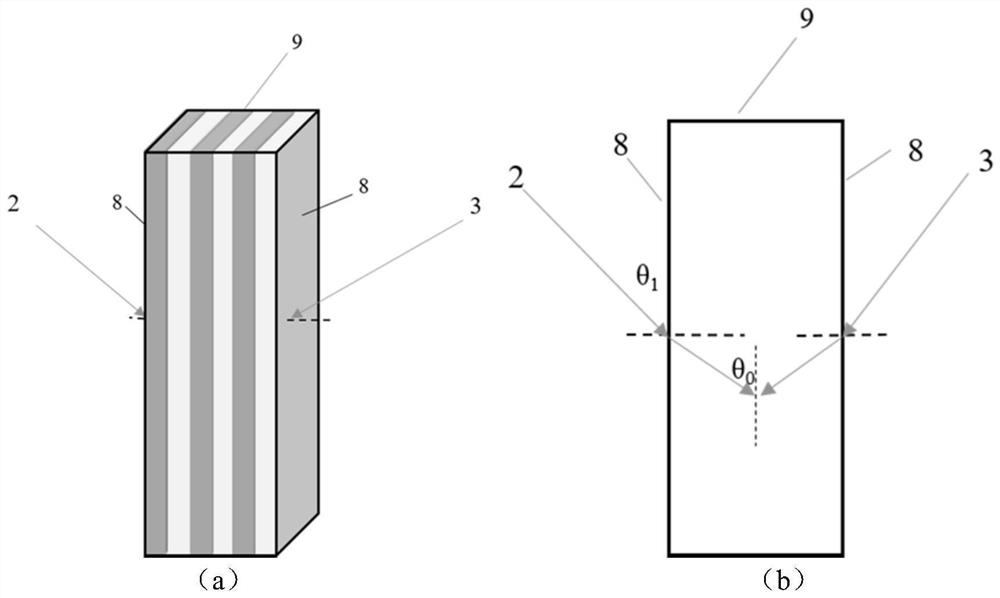

[0044] Embodiment 2: Prepare a reflective volume grating with a central wavelength of 376±0.5 nm by means of through-beam exposure.

[0045] (1) Polish the two incident surfaces 8 of the PTR glass 9 to be exposed.

[0046] (2) The refractive index n of PTR glass 9 at the use wavelength of 376nm av =1.52, calculate the exposure angle θ 0 is 59.8°, according to the refractive index, the incident angle θ 1 =49.85°.

[0047] (3) Use two beams of ultraviolet parallel light 2,3 with θ 1 The angle of =49.85° is directed onto the PTR glass 9, and after a certain dose of ultraviolet exposure, the exposure is stopped.

[0048] (4) After subsequent heat treatment and cutting, the first sample of the reflective volume grating is prepared, and its central wavelength is tested, and the steps (2) to (4) are continuously operated to adjust the exposure angle and the central wavelength test, so that the central wavelength falls within range of needs.

[0049] The method of the present in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com