Laser welding machine multi-station welding workbench

A laser welding machine, laser welding machine technology, applied in laser welding equipment, welding equipment, welding equipment and other directions, can solve the problems of low operation efficiency, high moving frequency, not suitable for batch processing of small spot welding parts and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

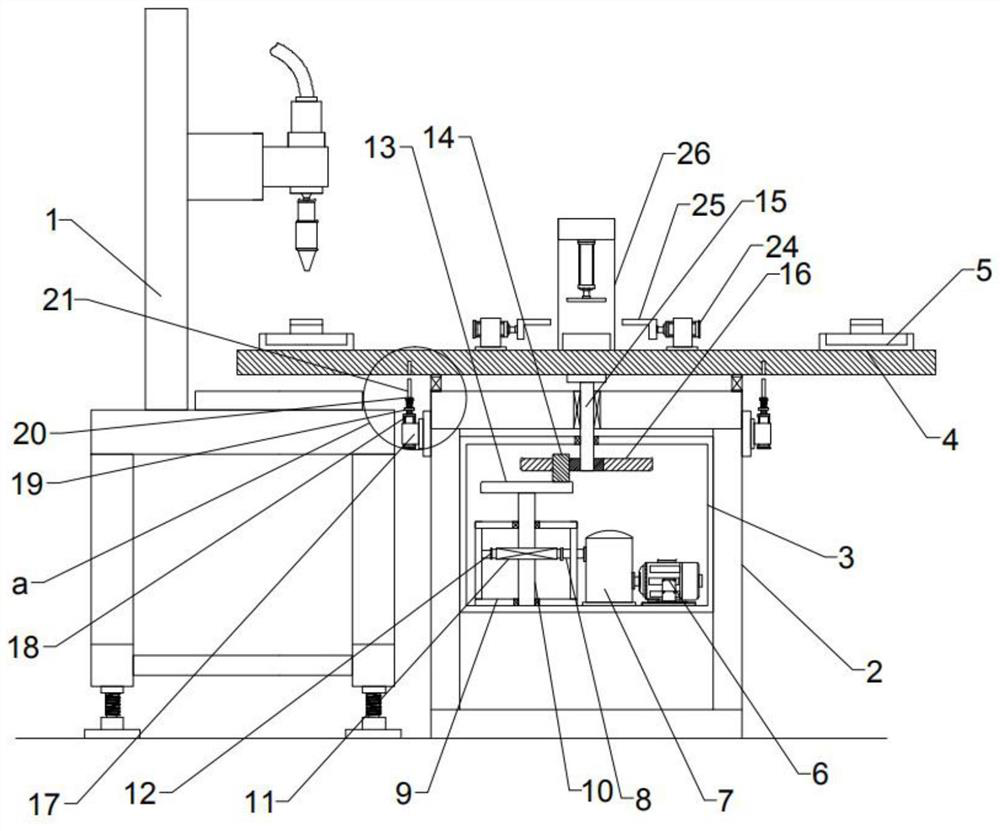

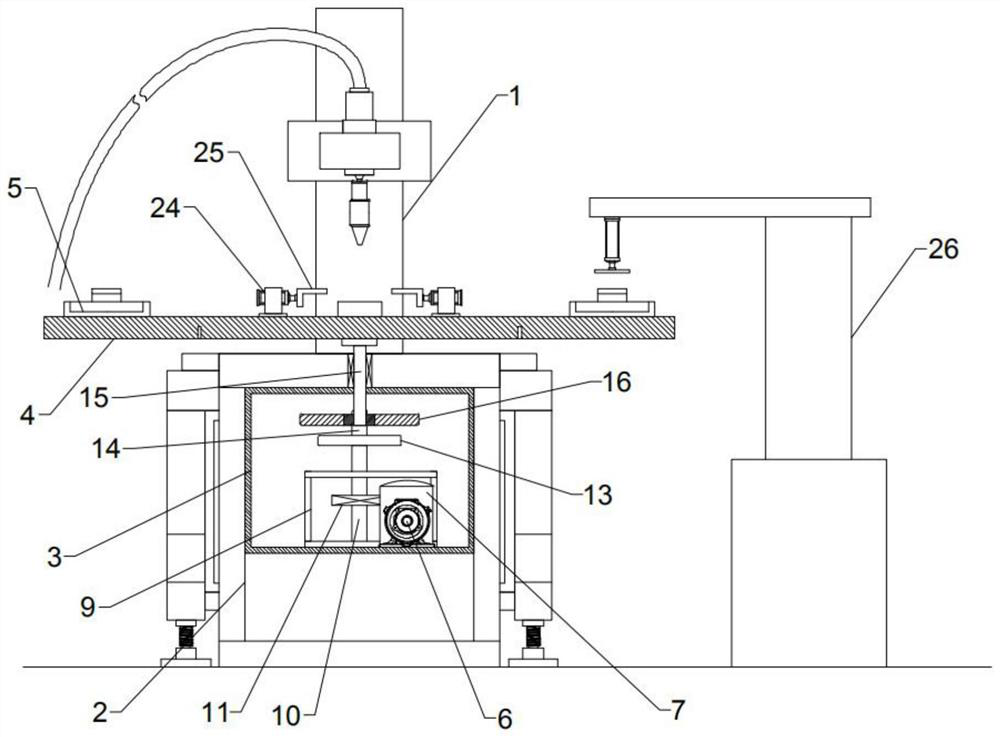

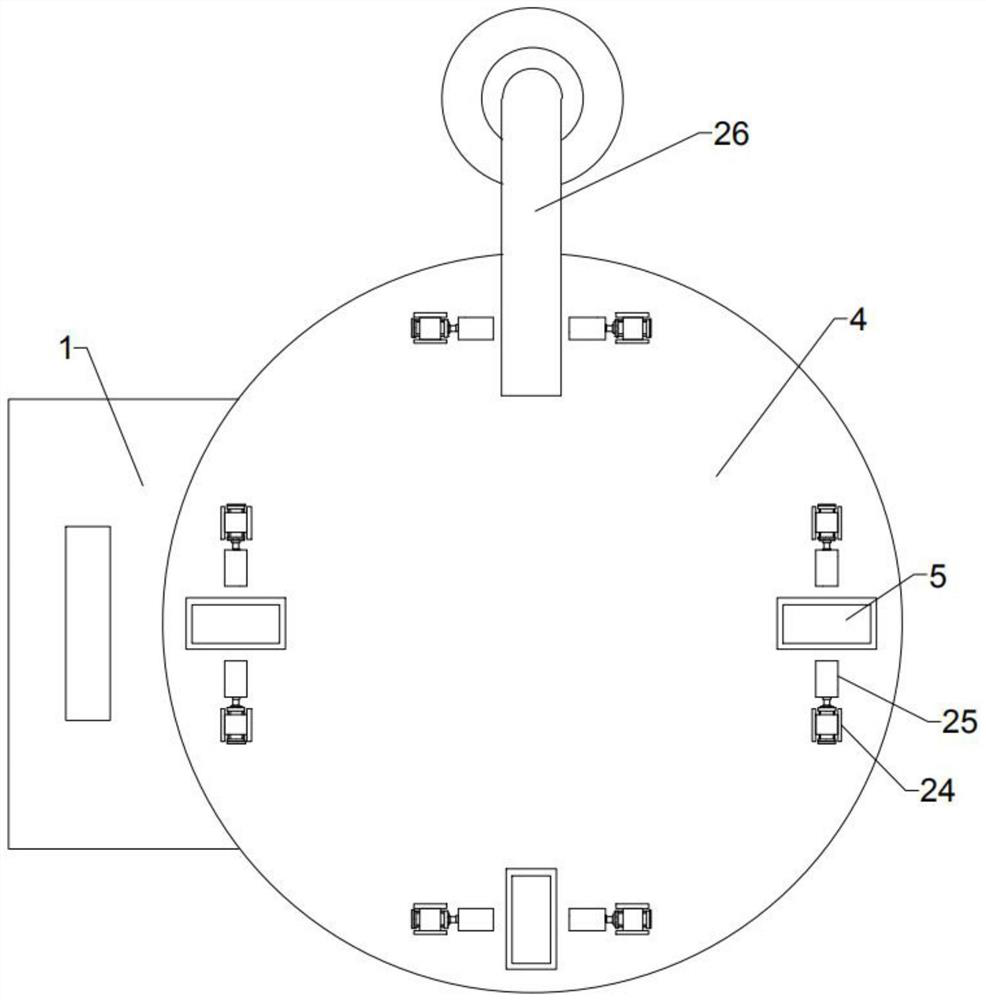

[0026] Embodiment: attached by specification Figure 1-7 It can be seen that this scheme includes the main body 1 of the laser welding machine, the side of the main body 1 of the laser welding machine is provided with a fixed frame 2, the fixed frame 2 is provided with an intermittent feeding mechanism, and the intermittent feeding mechanism is provided with a combined clamping mechanism, One side of the intermittent feeding mechanism is provided with a mechanical arm 26; the above-mentioned intermittent feeding mechanism includes: a box body 3, a drive control assembly, a transmission connection assembly and a turntable 4, and its positional relationship and connection relationship are as follows. The box body 3 is arranged on In the fixed frame 2, the drive control assembly is arranged in the box body 3, the transmission connection assembly is arranged in the box body 3, and one end is connected with the drive control assembly, and the other end extends out of the box body 3,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com