Hydrogen fuel cell four-wheel hub motor drive external controller and control method

An in-wheel motor and fuel cell technology, which is applied in the control drive, electric vehicle, control device, etc., can solve the problem of not having braking energy recovery and driving anti-skid functions, increasing the difficulty of controller software development, and consuming controller chip resources, etc. problems, to reduce the risk of load imbalance, save the development cycle, and increase the cruising range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

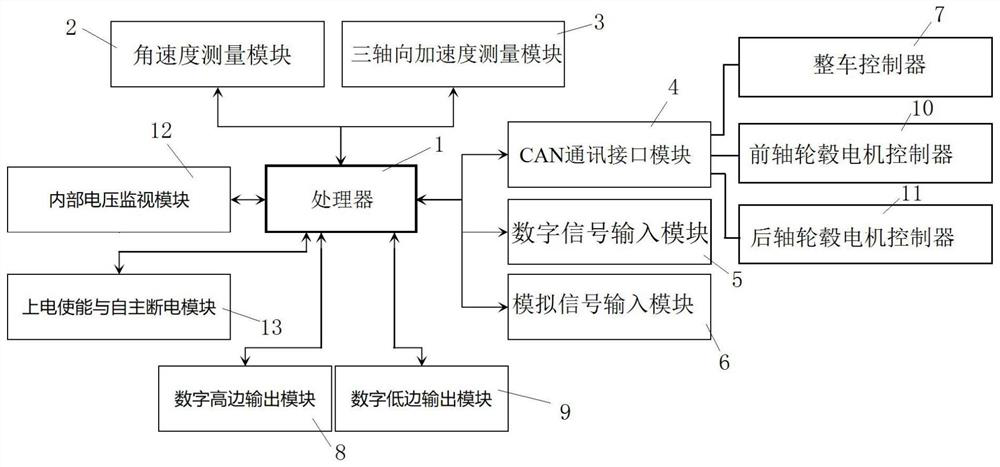

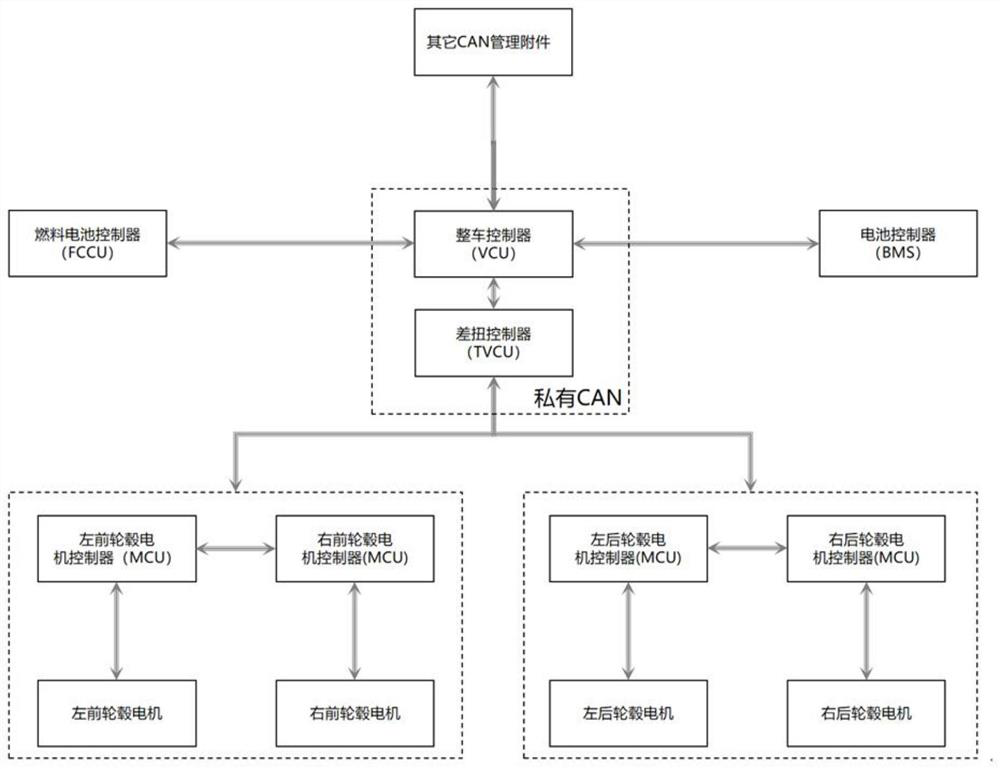

[0020] Such as figure 1 and 2 The shown hydrogen fuel cell four-wheel hub motor drive plug-in controller includes a processor 1, an angular velocity measurement module 2, a triaxial acceleration measurement module 3, a digital signal input module 5, an analog signal input module 6 and a digital high-side output module 8. Among them, the processor 1 can independently perform the self-inspection of the CPU unit, the clock unit, and the storage unit. When a failure occurs, a response interruption will be generated and the application program will be notified for processing. The angular velocity measurement module 2 is used to measure the real-time yaw angular velocity and pitch of the vehicle. Angular velocity and rolling angular velocity, the three-axis acceleration measurement module 3 is used to measure the real-time lateral acceleration, longi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com