Water-based paint applied to galvanized pipes and preparation method of water-based paint

A water-based paint, galvanized pipe technology, applied in coatings, anti-corrosion coatings, epoxy resin coatings, etc., can solve the problems of paint film peeling, poor adhesion, waste, etc., and achieve improved flexibility, hardness and weather resistance. , The effect of preventing rust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

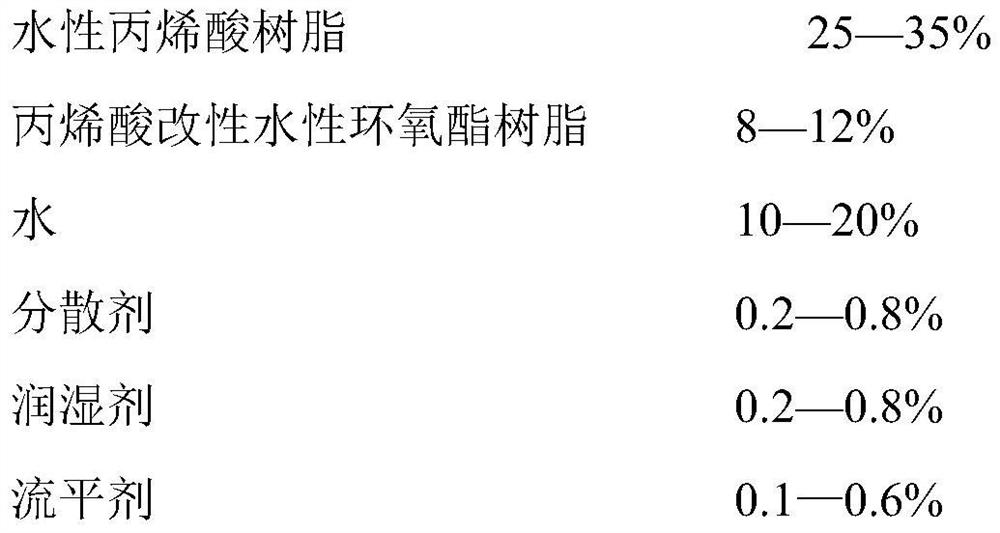

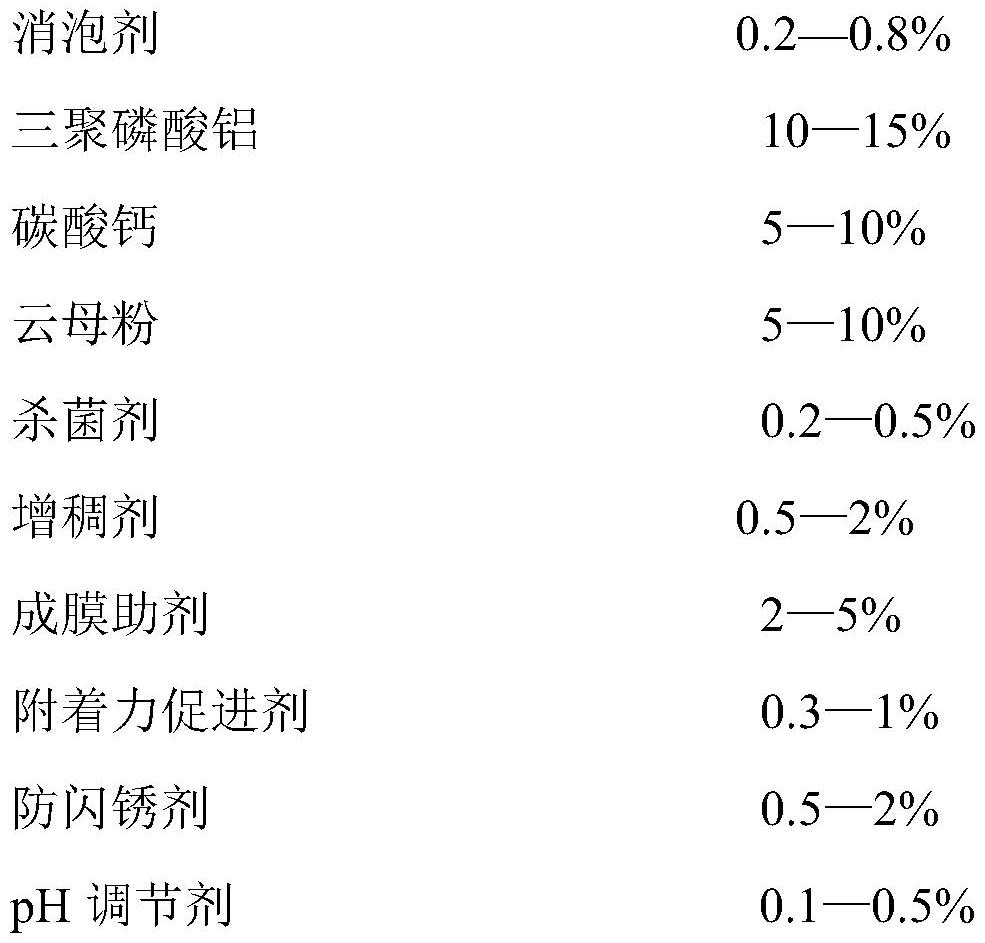

[0041] A water-based anti-rust white paint, comprising the following components, the weight percentage of each component is: water-based acrylic resin: 29%, acrylic modified water-based epoxy ester resin: 8%, composite aluminum tripolyphosphate: 12% ; Calcium carbonate: 5%; Mica powder: 5%; Adhesion promoter: 0.8%; Coating agent: 4%; Anti-flash rust agent: 1.2%; Wetting agent: 0.3%; defoamer: 0.5%; fungicide: 0.3%; PH regulator: 0.2%; thickener: 1.5%, water: 10.6%; water-based titanium white paste: 21%

[0042] Follow the steps below to prepare:

[0043] Put the above-mentioned dispersant, wetting agent, water and 50% defoamer into a high-speed mixing container, stir evenly at a slow speed, and then add composite aluminum tripolyphosphate, calcium carbonate, and mica powder at a constant speed while stirring at a high speed. Disperse until the scraper fineness is below 30 microns;

[0044] 2) Mix the above silicone-modified water-based acrylic resin, acrylic-modified water-b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com