Preparation method and application of hole transport layer nickel oxide film in perovskite battery

A technology of hole transport layer and perovskite battery, which is applied in the field of solar cells, can solve the problems of reducing device efficiency and affecting light transmittance, and achieve the effects of avoiding invalid deposition, easy area enlargement, and improving photoelectric conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

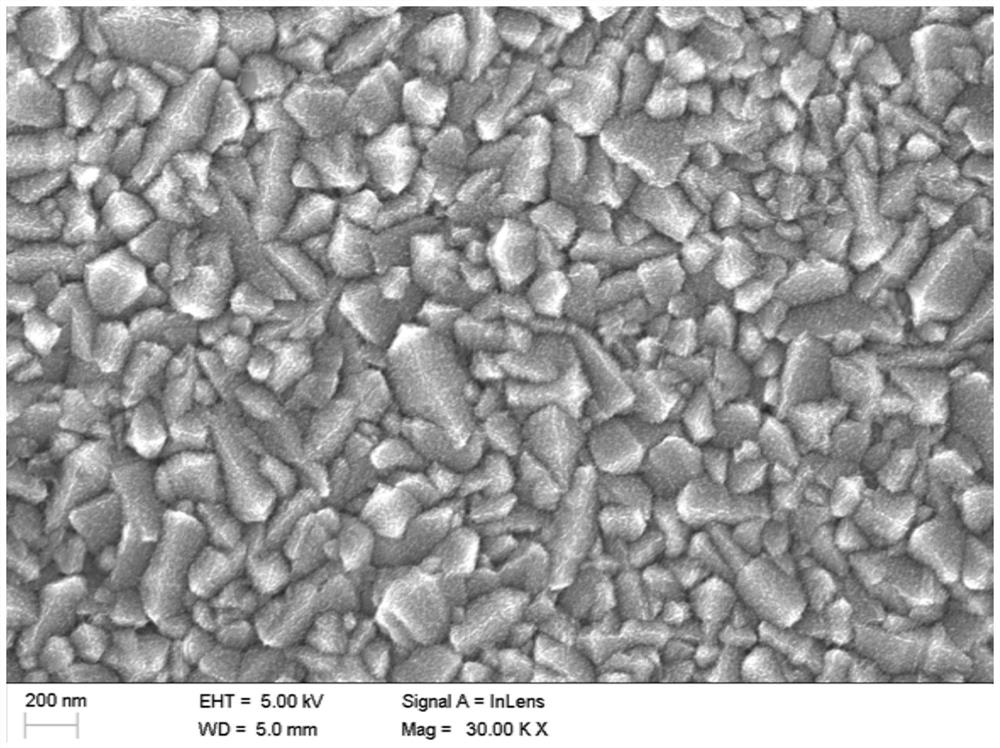

[0050] (1) Clean the conductive glass substrate sequentially with industrial cleaning agent, deionized water, and ethanol, and dry it with compressed air, then treat it with ultraviolet and ozone for 15 minutes.

[0051] (2) Add nickel sulfate and potassium persulfate into deionized water and stir to dissolve to obtain a precursor solution with a nickel source concentration of 0.1 mol / L and a potassium persulfate concentration of 0.018 mol / L.

[0052] (3) Alkali is added to the above precursor solution, and the pH value of the precursor solution is adjusted to 8.2.

[0053] (4) Suspend the conductive glass substrate above the precursor solution, make the conductive surface of the conductive glass substrate contact with the precursor solution, and perform chemical bath deposition for 440 s, so as to form a nickel oxide thin film precursor on the conductive surface of the substrate.

[0054] (5) Rinse the product obtained in step (4) with pure water, dry it with an air gun, put ...

Embodiment 2

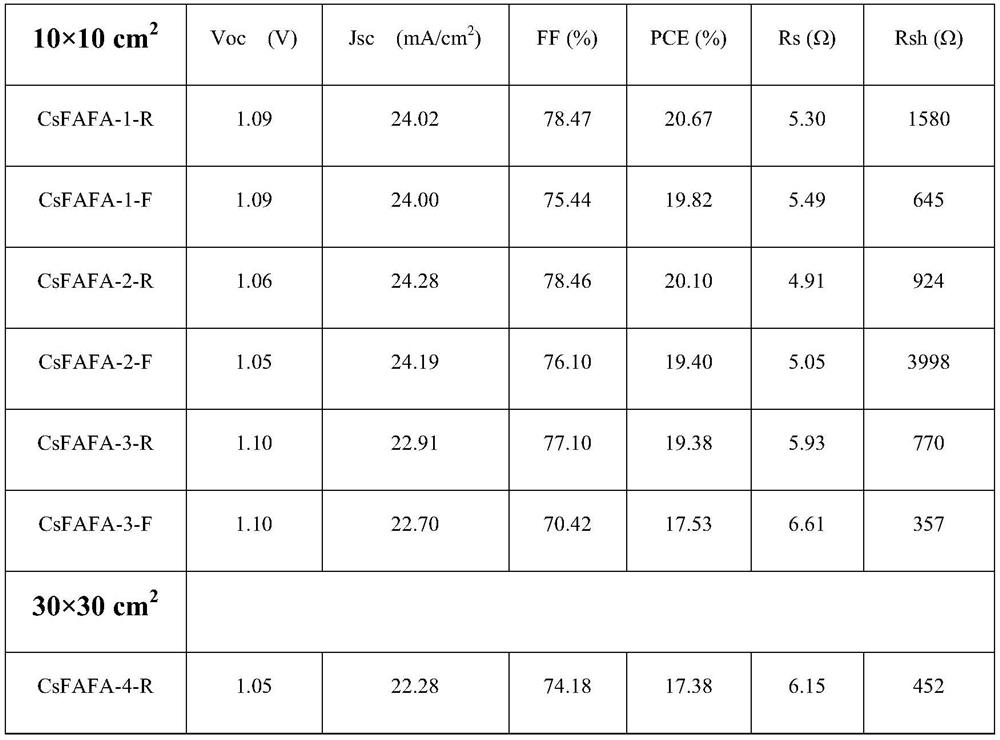

[0057] Multiple groups of conductive glass substrates formed with nickel oxide thin films prepared in Example 1 were taken respectively, and were further used to prepare perovskite batteries by the same method, and the photoelectric performance test of the obtained perovskite batteries was carried out. The results are shown in Table 1 .

[0058] Table 1 Photoelectric performance test results

[0059]

[0060]

[0061] It can be seen from the above table that the nickel oxide film prepared by the present invention is further used to prepare perovskite cells, and the photoelectric conversion efficiency of perovskite cells can be obtained above 20%. The 30cm×30cm large-area film layer was prepared, and the films in different regions were selected to prepare perovskite batteries. The difference in battery performance was small, indicating that the large-area film had good uniformity and was suitable for large-area industrial production applications.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| conversion efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com