A single cell and stack of a wave-shaped fuel cell

A fuel cell and wave-shaped technology, applied in the direction of fuel cells, circuits, electrical components, etc., can solve the problems of limited battery power density increase, difficulty in circulating cooling fluid, high mass production costs, etc., and achieve minimal changes in processing methods and assembly processes , Improve the effective area utilization rate and improve the power density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

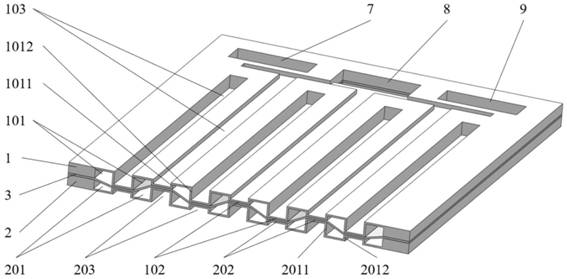

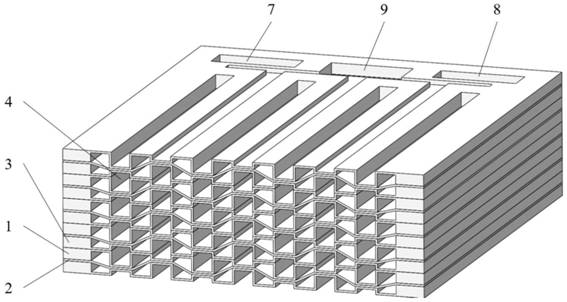

[0037] like figure 1 and figure 2 As shown, a wave-shaped fuel cell single cell, the single cell includes an anode plate 1, a cathode plate 2 and a membrane electrode assembly 3, the anode plate 1 is designed with a wave-shaped structure, on which a number of anode flow channels are arranged alternately in parallel 101 and the anode ridge plate 102, the cathode plate 2 adopts a wave-shaped structure design that meshes with the anode plate 1, on which a number of cathode flow channels 201 and cathode separators 202 are alternately arranged in parallel, and the anode flow channel 101 and the cathode flow channel are arranged alternately. 201 are parallel to each other. The membrane electrode assembly 3 is installed between the anode plate 1 and the cathode plate 2, and the entire single cell presents a wavy structure along the width direction of the flow channel.

[0038]Among them, anode plate 1 and cathode plate 2 are both processed and manufactured by metal sheet stamping ...

Embodiment 2

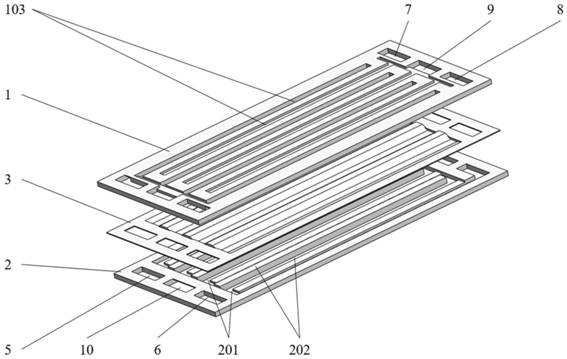

[0046] like Figure 4 and Figure 5 As shown, a wave-shaped fuel cell single cell, the single cell includes an anode plate 1, a cathode plate 2 and a membrane electrode assembly 3, the anode plate 1 is designed with a wave-shaped structure, on which a number of anode flow channels are arranged alternately in parallel 101 and anode ridge plate 102, the cathode plate 2 adopts a wave-shaped structure design that meshes with the anode plate 1, on which a number of cathode flow channels 201 and cathode ridge plates 202 are arranged alternately in parallel, and the anode flow channel 101 and the cathode flow channel are arranged alternately. 201 are parallel to each other. The membrane electrode assembly 3 is installed between the anode plate 1 and the cathode plate 2, and the entire single cell presents a wavy structure along the width direction of the flow channel.

[0047] Among them, anode plate 1 and cathode plate 2 are both processed and manufactured by metal sheet stamping ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com