Red mud modification method

A red mud modification technology, applied in the field of industrial waste residue modification, can solve the problems of affecting red mud soil, affecting the aesthetics of buildings, and high red mud bulk density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

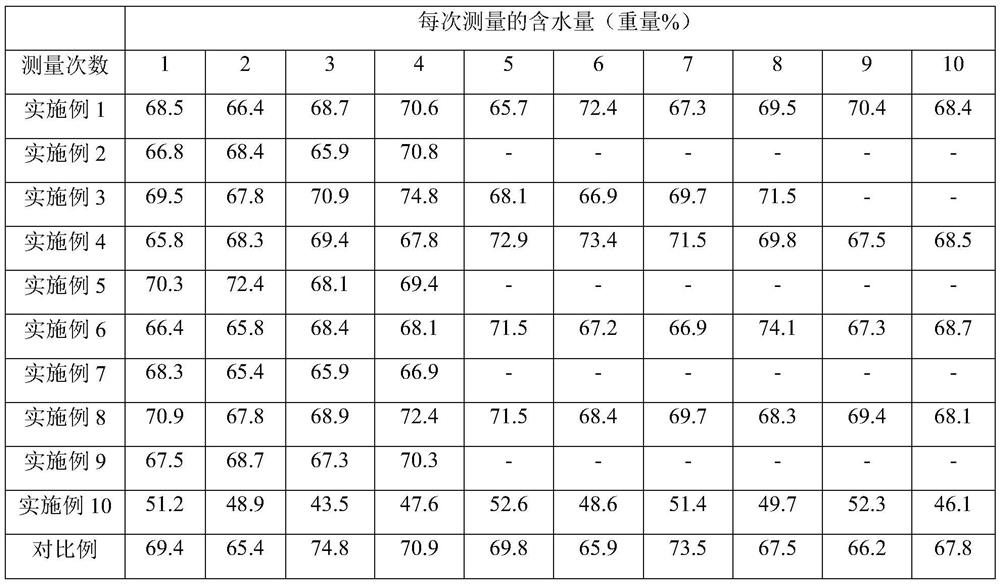

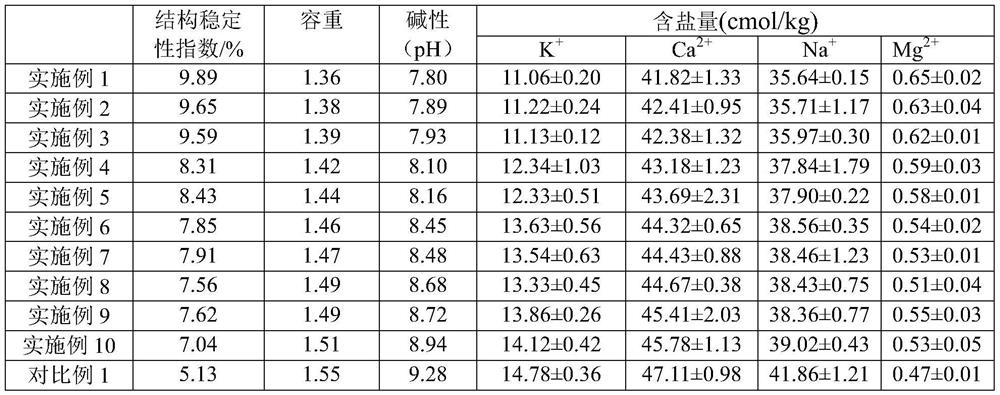

Examples

preparation example Construction

[0037] The mushroom compost can be obtained commercially or prepared. In order to further improve the structural stability of the red mud and increase the microbial activity and species abundance in the red mud, preferably, the preparation method of the mushroom compost comprises:

[0038] (1) mixing straw with livestock and poultry manure and water so that its water content is 40-50% by weight;

[0039] (2) mixing gypsum powder with the mixture obtained in step (1) to obtain base material;

[0040] (3) performing a primary fermentation on the base material to obtain a primary fermentation product;

[0041] (4) performing secondary fermentation on the primary fermentation product to obtain the mushroom compost;

[0042] Wherein, the dry weight ratio of the straw, the livestock manure and the gypsum powder is 1:0.2-2:0.2-2.

[0043] In order to further improve the structural stability of the red mud and increase the microbial activity and bacterial species abundance in the r...

preparation example 1

[0078] (1) Mix 5kg of corn stalks, 2kg of cow dung and 3kg of sheep dung evenly, then pour 8kg of water therein and mix evenly to obtain a mixture;

[0079] (2) Mix 5kg of gypsum-1 with the mixture obtained in step (1) to obtain base material;

[0080] (3) Start the fan so that the wind pressure of the primary fermentation tunnel is 2800Pa, place the base material obtained in step (2) in the primary fermentation tunnel for fermentation, and when the temperature rises above 70°C, keep it for 3 days. During the process, keep the temperature of the base material below 80°C, and then turn the fermentation product once to lower the temperature below 40°C;

[0081] (4) Move the primary fermentation product to the secondary fermentation tunnel for fermentation. When the temperature rises above 55°C, keep it for 10 hours. During this process, keep the temperature of the primary fermentation product below 60°C. After cooling down to below 35°C Decompose for 3 days to get Mushroom Comp...

preparation example 2

[0083] (1) Mix 5kg of corn stalks, 1kg of chicken manure and 1.5kg of sheep manure evenly, then pour 5kg of water therein and mix evenly to obtain a mixture;

[0084] (2) Mix 2.5kg of gypsum-2 with the mixture obtained in step (1) to obtain base material;

[0085] (3) Start the fan so that the wind pressure of the primary fermentation tunnel is 2500Pa, place the base material obtained in step (2) in the primary fermentation tunnel for fermentation, and when the temperature rises above 70°C, keep it for 3 days. During the process, keep the temperature of the base material below 80°C, and then turn the fermentation product once to lower the temperature below 40°C;

[0086] (4) Move the primary fermentation product to the secondary fermentation tunnel for fermentation. When the temperature rises above 55°C, keep it for 8 hours. During this process, keep the temperature of the primary fermentation product below 60°C. After cooling down to below 35°C Decompose for 5 days to get Mu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com