Feed for fattening beef cattle

A technology for beef cattle and fattening in the later stage, which is applied in the field of animal husbandry and can solve the problems of poor release and absorption of vitamins and amino acids, restrictions on the enthusiasm of beef cattle farmers, and low dry matter absorption and utilization, so as to improve the absorption and utilization rate and increase Effect of daily weight gain and improvement of production performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] A concentrate supplement for reducing rumen acidosis in the later stage of beef fattening, the specific ingredients of which are as follows: 300-400 kilograms of corn, 250-300 kilograms of barley kg, 150-200 kg of soybean meal, 50-150 kg of corn germ meal, 50-80 kg of corn DDGS, 8-15 kg of stone powder, 5-10 kg of calcium hydrogen phosphate, 5-10 kg of table salt, 2-3 kg of organic calcium and magnesium , 2-5 kg of yeast culture, 2-3 kg of active probiotics, 1-2 kg of trace element premix, 0.2-1 kg of rumen-passed vitamins, 1-3 kg of rumen-passed amino acids; among them, organic calcium and magnesium are A blend of calcium alginate and magnesium alginate.

[0018] The processing method of the supplementary concentrate in this embodiment is as follows: all the raw materials are crushed (bulk raw materials), mixed, and processed into a powdery or granular mixture; the supplementary concentrate is mainly used for fattening Angus beef cattle To reduce ruminal acidosis in...

Embodiment 2

[0022] A feed for beef cattle fed without grass during the fattening period. The specific ingredients are as follows: 50-100 kg of alfalfa powder, 50-100 kg of sunflower husks or sunflower discs, sucrose molasses 20-50 kg, corn 200-350 kg, husk barley 250-350 kg, soybean meal 50-150 kg, corn germ meal 30-120 kg, corn DDGS 30-60 kg, stone powder 5-15 kg, calcium hydrogen phosphate 3 ~10 kg, 3-10 kg of salt, 2-5 kg of organic calcium and magnesium, 2-10 kg of yeast culture, 2-5 kg of active probiotics, 1-2 kg of trace element premix, 0.5-5 kg of rumen-passing vitamins 1 kg, 2 to 5 kg of rumen-passed amino acids; among them, organic calcium and magnesium are a mixture of calcium alginate and magnesium alginate.

[0023] The processing method of the feed in this embodiment is that the above raw materials are crushed (bulk raw materials) and then added in a certain order, and the sucrose molasses is sprayed and mixed with a liquid to make a pellet feed with a suitable particl...

Embodiment 3

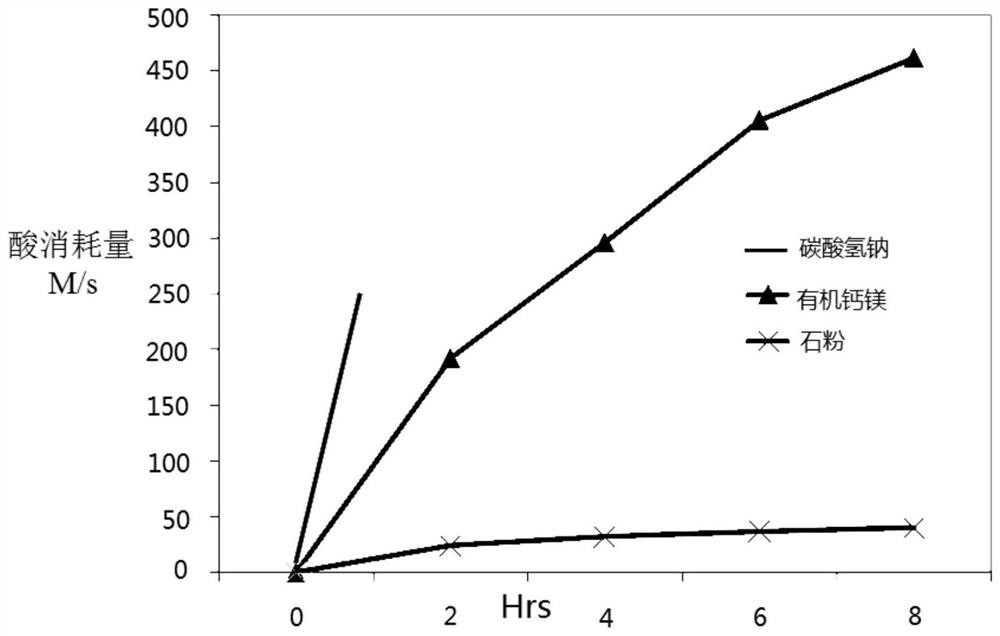

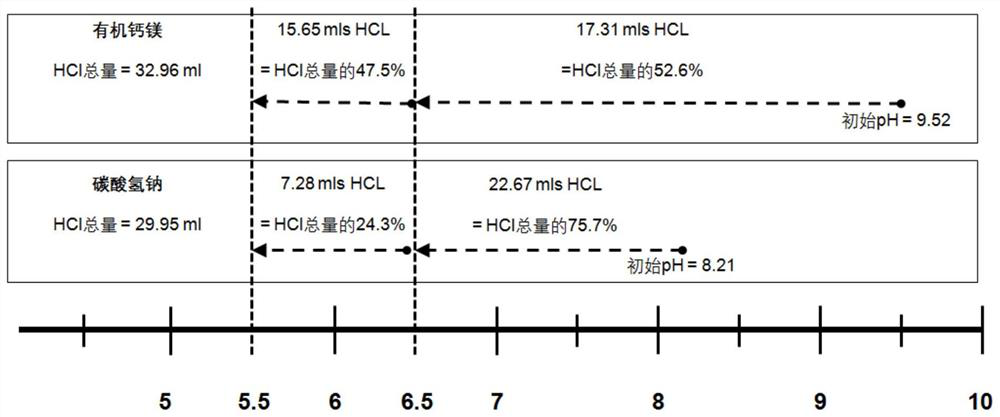

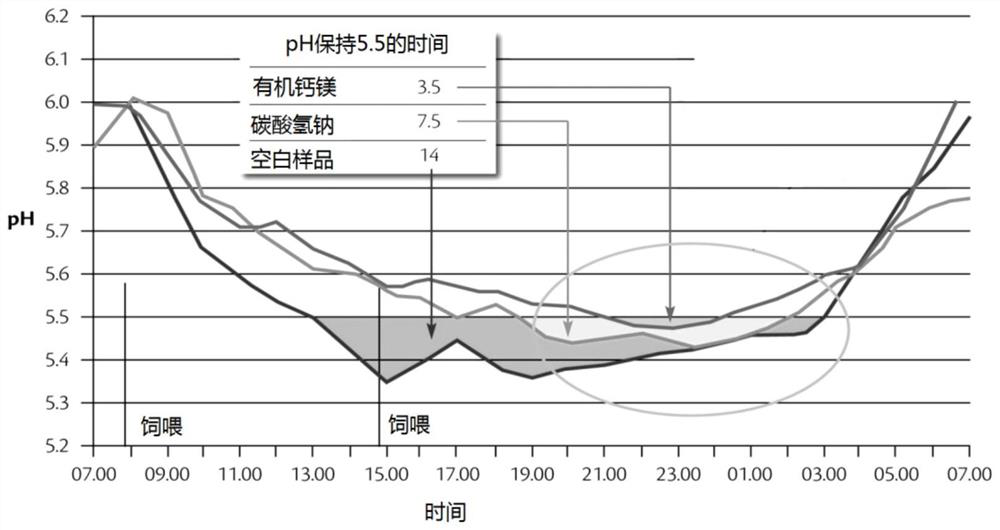

[0027] In the feed formulations of Examples 1 and 2, organic calcium and magnesium were added, and the effects of organic calcium and magnesium are now described as follows.

[0028] At present, sodium bicarbonate (commonly known as baking soda) is widely used in the feed of fattening cattle in China as a rumen buffer to adjust the pH value of the rumen. However, the regulating effect of sodium bicarbonate on the rumen is very limited. It will affect the palatability of the supplementary concentrate; while the organic calcium and magnesium have a better neutralizing effect on acid, which can stimulate the animals to ruminate continuously, keep the animals in a healthy rumen state for a long time, and effectively increase the dry matter intake; therefore, this Apply without the addition of sodium bicarbonate to relieve ruminal acidosis.

[0029] The test results related to the addition of organic calcium and magnesium are as follows.

[0030] figure 1 It is the comparison of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com