A kind of synthetic gas to make detergent higher alcohol catalyst and its preparation method and application

A technology for catalyst and synthesis gas, which is applied in catalyst activation/preparation, physical/chemical process catalyst, metal/metal oxide/metal hydroxide catalyst, etc. Restricted ASF distribution and other problems, to achieve the effect of good activity, mild reaction conditions, and improved selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

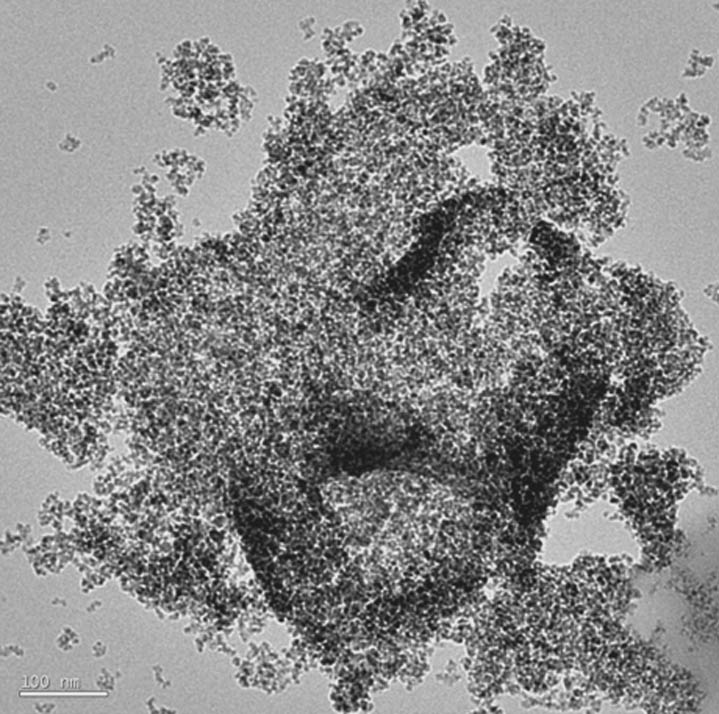

Image

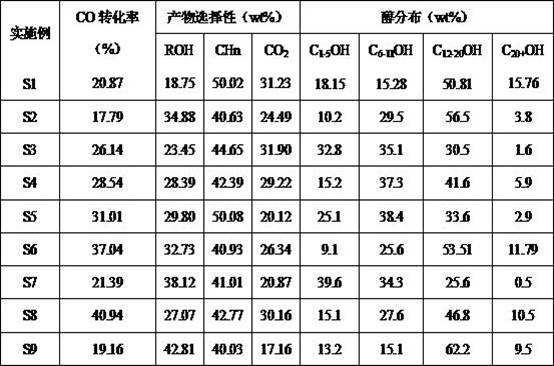

Examples

Embodiment 1

[0028] According to the catalyst composition, 0.242g Cu(NO 3 ) 2 ·3H 2 O, 4.04g Fe(NO 3 ) 3 9H 2 O, 0.291g Co(NO 3 ) 2 ·6H 2 Dissolve O in a mixture of 100mL ethanol and 20mL DMF and stir evenly to make a solution with a total metal molar concentration of 0.1mol / L, add 1.5g polyvinylpyrrolidone and stir evenly, then transfer the solution into a self-pressurized reactor at 170°C Stir and heat the reaction for 5 hours to obtain a well-dispersed nanoparticle suspension after the reaction;

[0029] Add 100mL of ethanol and 100mL of deionized water to disperse the above particle suspension, add 1.5g of cetyltrimethylammonium bromide, adjust the pH value to 9 with ammonia water, slowly add 5g of ethyl orthosilicate while stirring, After reacting for 12 hours, washing 4 times, drying, and roasting at 550°C, the catalyst powder was obtained;

[0030] Weigh the above catalyst powder and use CsNO 3impregnated with an equal volume of aqueous solution, dried at 80°C, and calcine...

Embodiment 2

[0033] According to the catalyst composition, 0.968g Cu(NO 3 ) 2 ·3H 2 O, 2.424g Fe(NO 3 ) 3 9H 2 O, 0.582g Co(NO 3 ) 2 ·6H 2 Dissolve O in a mixture of 100mL ethanol and 20mL DMF and stir evenly to make a solution with a total metal molar concentration of 0.1mol / L, add 1.5g polyvinylpyrrolidone and stir evenly, then transfer the solution into a self-pressurized reactor at 170°C Stir and heat the reaction for 5 hours to obtain a well-dispersed nanoparticle suspension after the reaction;

[0034] Add the above particle suspension to 100mL ethanol and 100mL deionized water to disperse, add 1.5g octadecyltrimethylammonium bromide, adjust the pH value to 9 with ammonia water, slowly add 7g ethyl orthosilicate while stirring, After reacting for 12 hours, washing 4 times, drying, and roasting at 550°C, the catalyst powder was obtained;

[0035] Weigh the above catalyst powder and use K 2 CO 3 impregnated with an equal volume of aqueous solution, dried at 80°C, and calcine...

Embodiment 3

[0038] According to the catalyst composition, 0.726g Cu(NO 3 ) 2 ·3H 2 O, 2.828g Fe(NO 3 ) 3 9H 2 O, 0.582g Ni(NO 3 ) 2 ·6H 2 Dissolve O in a mixture of 100mL ethanol and 20mL DMF and stir evenly to make a solution with a total metal molar concentration of 0.1mol / L, add 1.5g polyvinylpyrrolidone and stir evenly, then transfer the solution into a self-pressurized reactor at 180°C Stir and heat the reaction for 3 hours to obtain a well-dispersed nanoparticle suspension after the reaction;

[0039] Add 100mL of ethanol and 100mL of deionized water to disperse the above particle suspension, add 3g of octadecyltrimethylammonium bromide, adjust the pH value to 9 with ammonia water, slowly add 5g of ethyl orthosilicate under stirring conditions, and react After 12 hours, after washing 4 times, drying, and roasting at 550°C, the catalyst powder was obtained;

[0040] Weigh the above catalyst powder, use Cs 2 CO 3 impregnated with an equal volume of aqueous solution, dried a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com