Precision casting equipment for automobile parts based on investment casting

An auto parts and precision casting technology, applied in the field of auto parts casting, can solve the problems of low degree of automation, low production efficiency, only natural air drying, etc., and achieves the effects of high production efficiency, convenient operation and improved melt properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

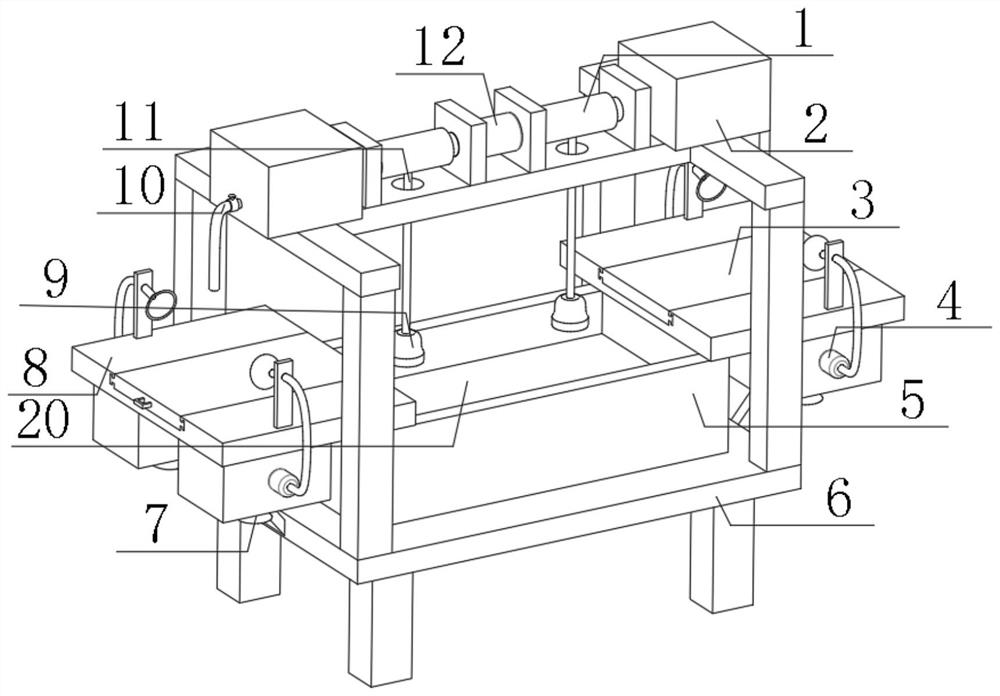

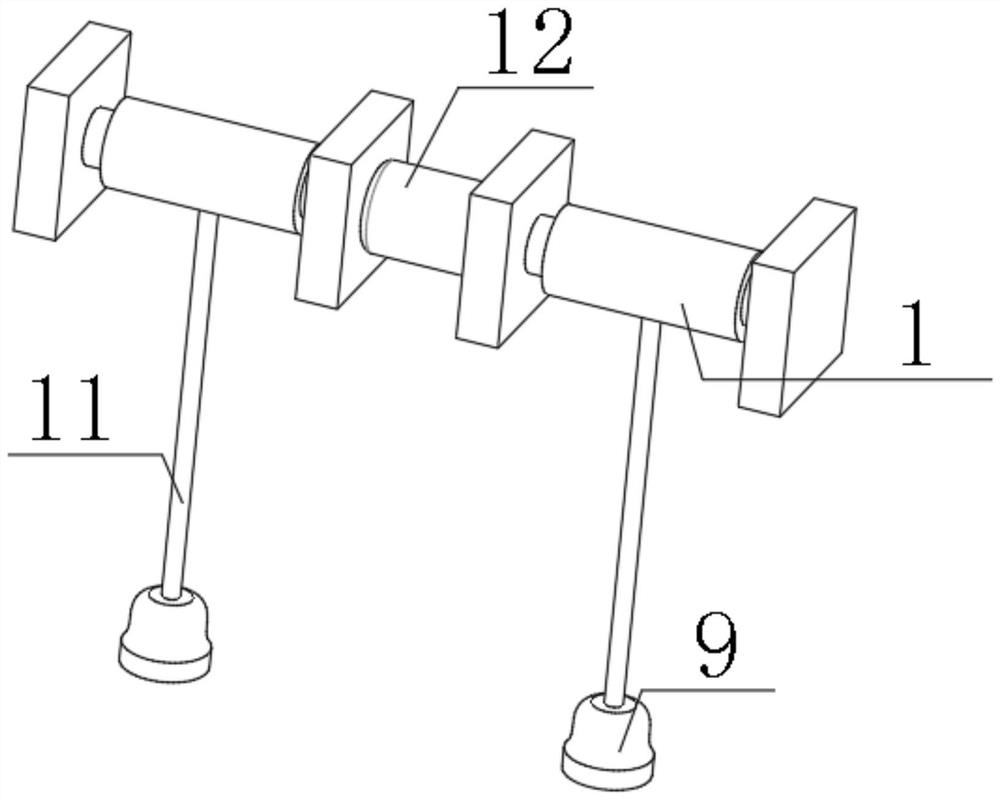

[0030] refer to Figure 1-3 , a precision casting equipment for auto parts based on investment casting, including a workbench 6, the top outer wall of the workbench 6 is fixed with a mud tank 5 by bolts, and the four corners of the top outer wall of the workbench 6 are fixed with installation rods by bolts, and the installation The top outer wall of the bar is fixed with a horizontal plate 17 by bolts, the outer walls of both sides of the top outer wall of the horizontal plate 17 are fixed with side plates by bolts, and the outer wall of one side of the side plate is fixed with a double-axis motor 12 by bolts, and the output of the double-axis motor 12 The shaft is connected with a winding roller 1 through a coupling, the outer wall of the winding roller 1 is bolted with a tension rope 11, one end of the tension rope 11 is bolted with a wax mold 9, the outer wall of the installation rod is provided with an air-drying mechanism, and the horizontal plate 17 Both sides of the top...

Embodiment 2

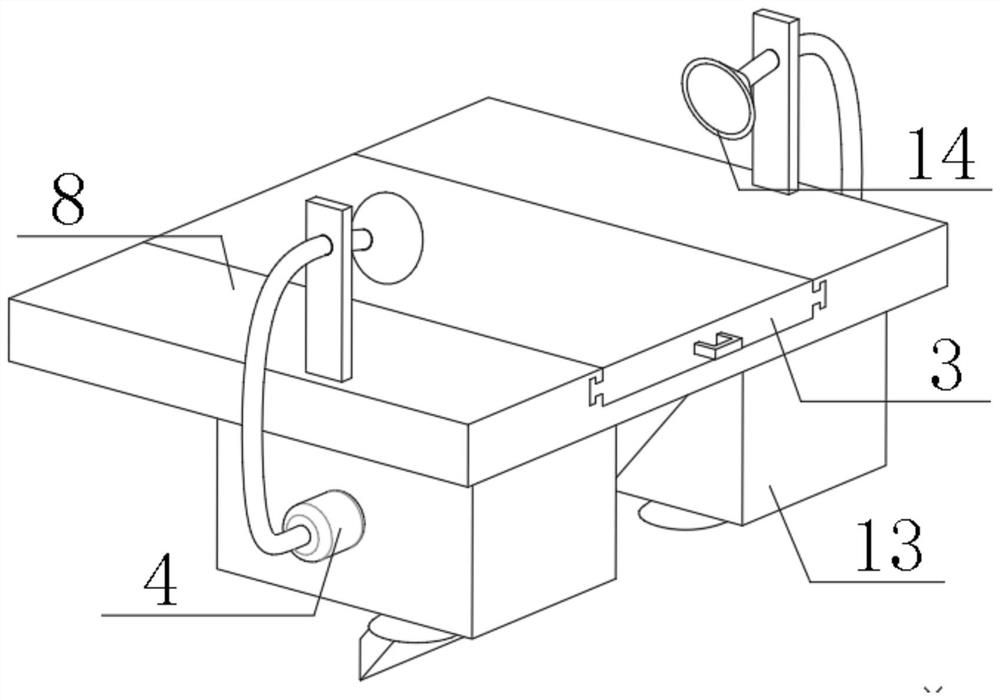

[0038] refer to Figure 4 Compared with Embodiment 1, this embodiment further includes a pull rod 16 slidably connected to the inner wall of the sliding hole, and a pull hook 19 is fixed at one end of the pull rod 16 by a bolt.

[0039] During use, after the wax mold 9 is hung up by the tension rope 11, people can hold the pull rod 16, control the pull hook 19 to enclose the tension rope 11, and then pull the wax mold 9 onto the slide plate 3, which is easy to operate and will not People's hands create pollution.

Embodiment 3

[0041] refer to Figure 5 Compared with Embodiment 2, this embodiment also includes that the bottom outer wall of the horizontal plate 17 is fixed with an illuminating lamp 18 by bolts.

[0042] When in use, when the brightness of the surrounding environment is low, the lighting lamp 18 can be turned on to illuminate the surrounding environment, thereby facilitating people to continue manufacturing auto parts and improving the manufacturing efficiency of parts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com