Welding process method for Q500qENH weather-resistant steel corner joint in alpine region

A fillet joint and welding process technology, applied in welding equipment, welding accessories, manufacturing tools, etc., can solve the problems of poor welding performance and difficulty in conformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] A process method for welding Q500qENH weathering steel fillet joints in alpine regions, said process method comprising:

[0059] (1) Welding surface pretreatment

[0060] (1) Grinding the welding surface and adjacent areas to remove surface rust and other sundries;

[0061] (2) Welding surface cutting treatment

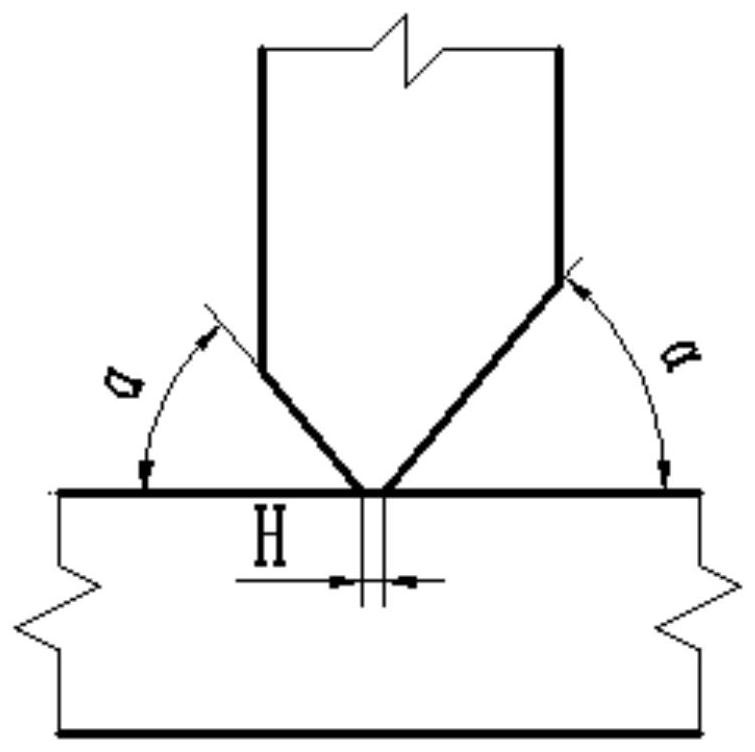

[0062] (2) The weld seam adopts double-sided asymmetric groove, the length of the blunt side is 2mm, the center of the blunt side is located near the center of the welded plate, and the distance from the center of the blunt side to the edge of the far-end welded plate accounts for 10% of the overall thickness of the plate The ratio is 0.55; the groove angle is 45°;

[0063] (3) Grinding again to remove metal debris, and then butt the blunt edge of the welded plate with the substrate;

[0064] (3) Fillet joint welding forming process

[0065] (4) Welding: Use welding wire with a tensile strength of deposited metal ≥ 650MPa to weld the groove;

[0066] (5) T...

Embodiment 2

[0075] A process method for welding Q500qENH weathering steel fillet joints in alpine regions, said process method comprising:

[0076] (1) Welding surface pretreatment

[0077] (1) Grinding the welding surface and adjacent areas to remove surface rust and other sundries;

[0078] (2) Welding surface cutting treatment

[0079] (2) The weld seam adopts double-sided asymmetric groove, the length of the blunt side is 2mm, the center of the blunt side is located near the center of the welded plate, and the distance from the center of the blunt side to the edge of the far-end welded plate accounts for 10% of the overall thickness of the plate The ratio is 0.618; the groove angle is 50°;

[0080] (3) Grinding again to remove metal debris, and then butt the blunt edge of the welded plate with the substrate;

[0081] (3) Fillet joint welding forming process

[0082] (4) Welding: Use welding wire with a tensile strength of deposited metal ≥ 650MPa to weld the groove;

[0083] (5) ...

Embodiment 3

[0092] A process method for welding Q500qENH weathering steel fillet joints in alpine regions, said process method comprising:

[0093] (1) Welding surface pretreatment

[0094] (1) Grinding the welding surface and adjacent areas to remove surface rust and other sundries;

[0095] (2) Welding surface cutting treatment

[0096] (2) The weld seam adopts double-sided asymmetric groove, the length of the blunt side is 2mm, the center of the blunt side is located near the center of the welded plate, and the distance from the center of the blunt side to the edge of the far-end welded plate accounts for 10% of the overall thickness of the plate The ratio is 0.65; the groove angle is 50°;

[0097] (3) Grinding again to remove metal debris, and then butt the blunt edge of the welded plate with the substrate;

[0098] (3) Fillet joint welding forming process

[0099] (4) Welding: Use welding wire with a tensile strength of deposited metal ≥ 650MPa to weld the groove;

[0100] (5) The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com