Regeneration and utilization system of diamond wire cooling liquid

A technology of coolant and diamond wire, applied in water treatment parameter control, special treatment targets, water/sludge/sewage treatment, etc., can solve problems such as high cost of coolant use, unqualified environmental protection assessment, and excessive COD emissions. Achieve the effect of improving the level of environmental protection, improving the quality of environmental protection, and reducing the amount of waste liquid discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

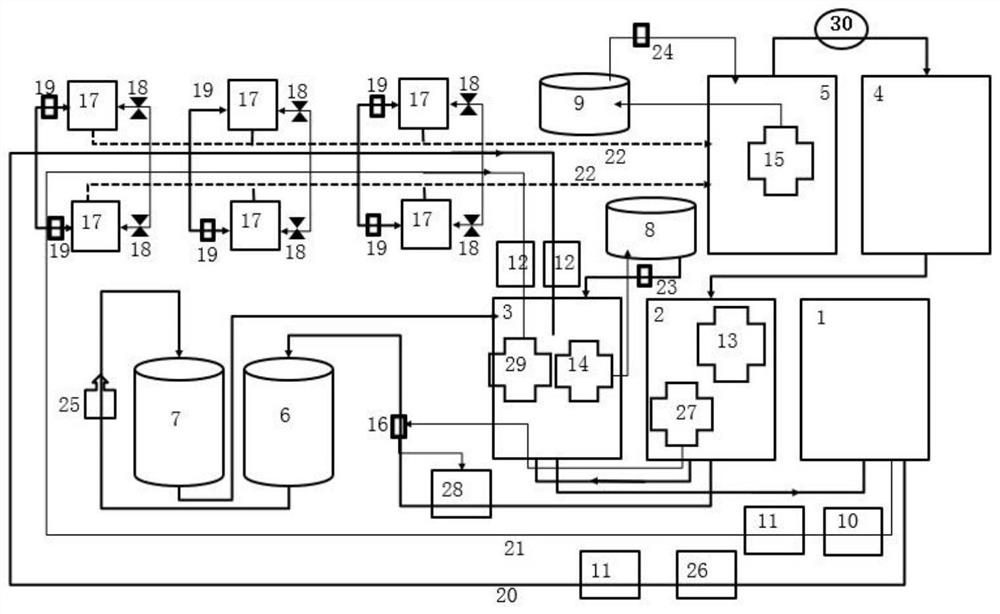

[0016] The present invention will be further described in detail below in conjunction with the accompanying drawings.

[0017] Such as figure 1 As mentioned above, the present invention provides a diamond wire coolant regeneration and utilization system, including a first liquid storage tank 1, the first liquid storage tank 1 is equipped with a configured water-soluble diamond wire cutting coolant; pipelines 20, The liquid inlet ends of 21 and 21 are respectively connected with the first liquid storage tank 1 , and the liquid outlet ends are respectively connected with the third liquid storage tank 3 . The pipeline 20 is used to replenish the prepared coolant to the third liquid storage tank 3 , and the pipeline 21 is used to replace the waste coolant in the third liquid storage tank 3 . Pipelines 20 and 21 are respectively provided with branches for delivery to the slicer slurry cylinder 17, and the slicer slurry cylinder 17 is provided with multiple, every two as a group, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com