Composite extractant for extracting oxygen-containing compounds in C5 hydrocarbon raw material and method for treating oxygen-containing compounds in C5 hydrocarbons

A compound extractant and extractant technology, applied in the refining of hydrocarbon oil, petroleum industry and other directions, can solve the problems of easy loss and large loss of olefin, and achieve the effects of simple device, low cost and excellent removal effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The non-alcoholic polar extractant furfural is compounded with the organic alcohol 1,4-butanediol, wherein the furfural is 50% by weight and the 1,4-butanediol is 50% by weight.

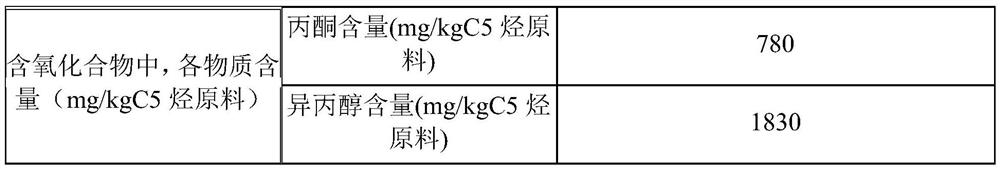

[0041]Put 150mL of the by-product C5 hydrocarbon raw material produced by Fischer-Tropsch naphtha cracking into ethylene, fully mix it with 300mL of composite extractant at a temperature of 10°C and a pressure of 0.05MPa, and put it into a glass reactor with mechanical stirring, and seal the reactor In good condition, the rotation speed is 400r / min. After stirring for 30 minutes, put the mixed material into a pear-shaped separatory funnel and let it stand for 10 minutes to separate. Take out the oil phase and wash it with water equal to the volume of the oil. Remove the carried extractant from the water The phase is carried out, and the upper oil phase is taken for analysis, and the above steps are repeated for 5 times. At the same time, the extractant is recovered by rectification. The rectifi...

Embodiment 2

[0043] Compound non-alcoholic polar extractant dimethyl sulfoxide and organic alcohol ethylene glycol, wherein the weight percentage of dimethyl sulfoxide is 80%, and the weight percentage of ethylene glycol is 20%.

[0044] Put 60mL of the by-product C5 hydrocarbon raw material produced by Fischer-Tropsch naphtha cracking into ethylene, at a temperature of 20°C and a pressure of 0.086MPa, fully mix it with 300mL of a composite extractant, put it into a glass reactor with mechanical stirring, and seal the reactor In good condition, the rotation speed is 600r / min. After stirring for 60 minutes, put the mixed material into the pear-shaped separatory funnel and let it stand for 15 minutes to separate. Take out the oil phase and wash it with water equal to the volume of the oil. Remove the carried extractant from the water The phase is taken out, the upper oil phase is taken for analysis, the extraction method is repeated twice, and the extractant is recovered by rectification. The...

Embodiment 3

[0046] The non-alcoholic polar extractant N-methylpyrrolidone is compounded with organic alcohol methanol, wherein the weight percent of N-methylpyrrolidone is 60%, and the weight percent of methanol is 40%.

[0047] Put 300mL of the by-product C5 hydrocarbon raw material produced by Fischer-Tropsch naphtha cracking into ethylene, fully mix it with 300mL of composite extractant at a temperature of 30°C and a pressure of 0.1MPa, and put it into a glass reactor with mechanical stirring, and seal the reactor In good condition, the rotation speed is 500r / min, after stirring for 90 minutes, put the mixed material into the pear-shaped separatory funnel and let it stand for 20 minutes to separate, take out the oil phase, wash it with water equal to the volume of the oil, and remove the carried extractant from the water The phase is carried out, and the upper oil phase is taken for analysis, and the above steps are repeated for 4 times. At the same time, the extractant is recovered by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com