Acidic cleaning agent as well as preparation method and application thereof

An acid cleaning agent and surfactant technology, which can be applied in the direction of surface active detergent composition, detergent composition, detergent compounding agent, etc., and can solve the problems of bluing, scratching, glass corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0064] One embodiment of the present invention also provides a preparation method of the above-mentioned acid cleaning agent, including the following step S10.

[0065] Step S10 , mix water, organic acid, inorganic acid, reducing agent, pH buffering agent, chelating agent and surfactant according to the composition ratio of the above-mentioned acidic cleaning agent to obtain an acidic cleaning agent.

[0066] Specifically, in step S10, organic acid, inorganic acid, reducing agent, pH buffering agent, chelating agent and surfactant are sequentially added to water, stirred and mixed, and diluted 10-15 times for use.

[0067] An embodiment of the present invention also provides the application of the above-mentioned acid cleaning agent in cleaning glass.

[0068] In some of the embodiments, the above glass is polished glass with rare earth polishing powder remaining on its surface.

[0069] Rare earth polishing powder is a rare earth based polishing powder, including but not lim...

Embodiment 1

[0074] Specific steps are as follows:

[0075] 1) Provide 500 pieces of polished glass, the polishing powder used is: cerium oxide.

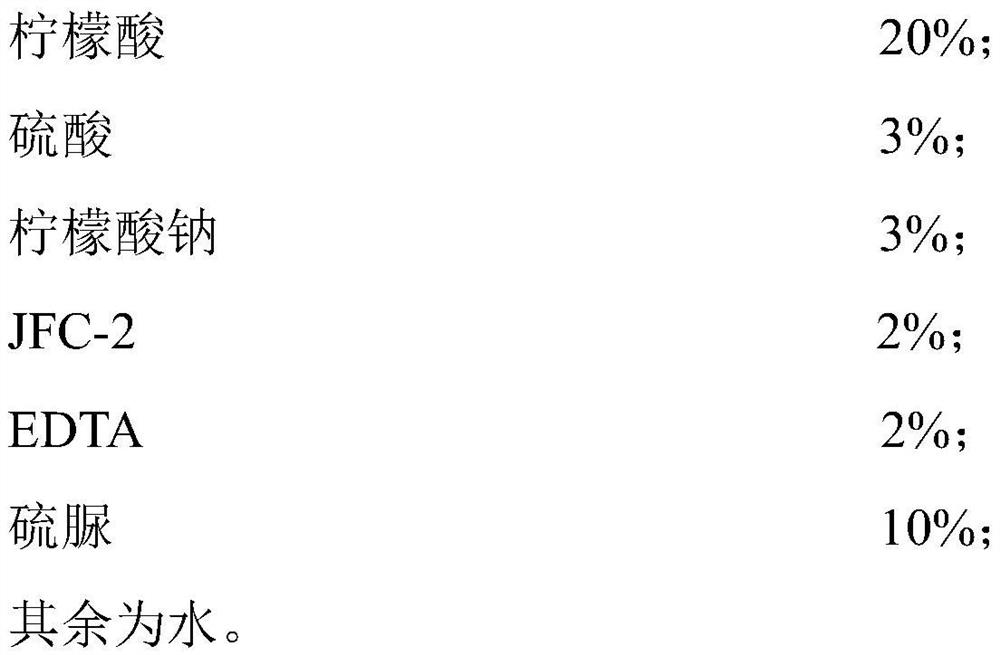

[0076] 2) Provide an acidic cleaning agent comprising the following mass percentage components, and the pH value of the acidic cleaning agent is 0.8.

[0077]

[0078] Dilute the acid cleaning agent provided in step 2) by 10 times with water and set aside.

[0079] 3) The polished glass is placed in a diluted acid cleaning agent, ultrasonically cleaned for 130 s, rinsed and dried after cleaning, and cleaned glass is obtained.

[0080] 4) Detect whether polishing powder remains on the cleaned glass obtained in step 3) and whether there is scratch.

[0081] 5) Take the polished glass of the same batch, and repeat the operation of step 3) in the same cleaning solution that has cleaned the glass in step 3), that is, clean and detect 500 pieces of polished glass in the same cleaning solution in total, and record the process. The number of piece...

Embodiment 2

[0083] Specific steps are as follows:

[0084] 1) Provide 500 pieces of polished glass, the polishing powder used is: cerium oxide.

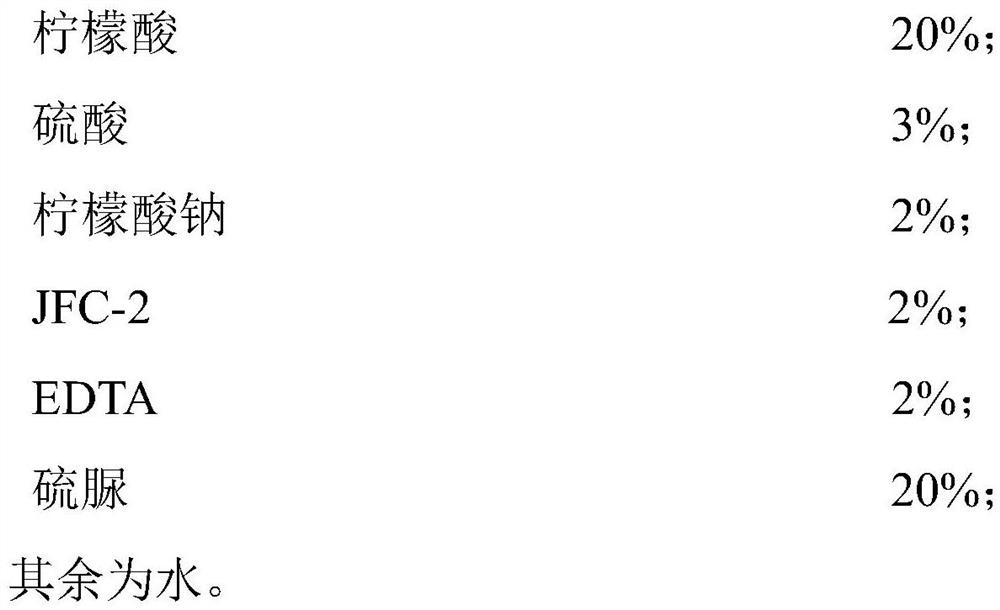

[0085] 2) provide the acid cleaning agent comprising the components of the following mass percentages, and the pH value of the acid cleaning agent is 0.6:

[0086]

[0087] Dilute the acid cleaning agent provided in step 2) by 10 times with water and set aside.

[0088] 3) The polished glass is then placed in a diluted acid cleaning agent, ultrasonically cleaned for 130 s, rinsed and dried after cleaning, and cleaned glass is obtained.

[0089] 4) Detect whether polishing powder remains on the cleaned glass obtained in step 2) and whether there is scratch.

[0090] 5) Take the polished glass of the same batch, and repeat the operation of step 3) in the same cleaning solution that has cleaned the glass in step 3), that is, clean and detect 500 pieces of polished glass in the same cleaning solution in total, and record the process. The numbe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com