Fermentation method of L-lysine

A fermentation method, lysine technology, applied in the direction of microorganism-based methods, fermentation, biochemical equipment and methods, etc., can solve the problems of slow growth, reduced economic benefits, slow growth of bacteria, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

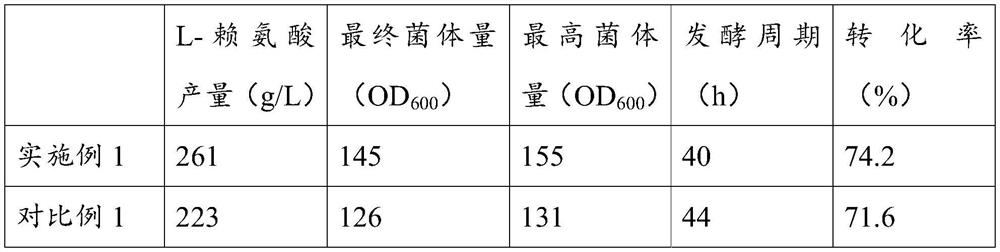

Examples

Embodiment 1

[0024] A method for producing L-isoleucine by fermentation, the specific method is as follows:

[0025] (1) Inoculate the L-lysine-producing bacteria Corynebacterium glutamicum in a bacterial preservation tube stored at -80°C on a slant medium for activation, and culture at a constant temperature of 32°C for 12 hours.

[0026] (2) Inoculate the bacteria on the slope into three 1L Erlenmeyer flasks, which contain 100mL of primary seed medium, adjust the pH to 7.0-7.2 with ammonia water, shake at 220rpm / min, and cultivate at a constant temperature of 32°C for 8-9h. OD 600 Get to around 20.

[0027] (3) Connect three 100mL primary seed liquids and 100mL 80% glucose into a 5L fermenter, which contains 2.6L seed culture medium, and control the fermentation temperature at 32°C, dissolved oxygen at 30-50%, and pH7. 0, when the dissolved oxygen is lower than 30%, increase the speed and air volume. Grow to OD 600 ≥25, seed age 21-23h.

[0028] (4) Release the seed liquid to the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com