Bio-based amino resin re-tanning agent and preparation method thereof

A technology of amino group and retanning agent, applied in the field of bio-based amino resin retanning agent and its preparation, can solve the problems of poor water solubility, low addition amount of amino compounds, structural transformation, etc., and achieves improved penetration performance, good filling performance, Good retanning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

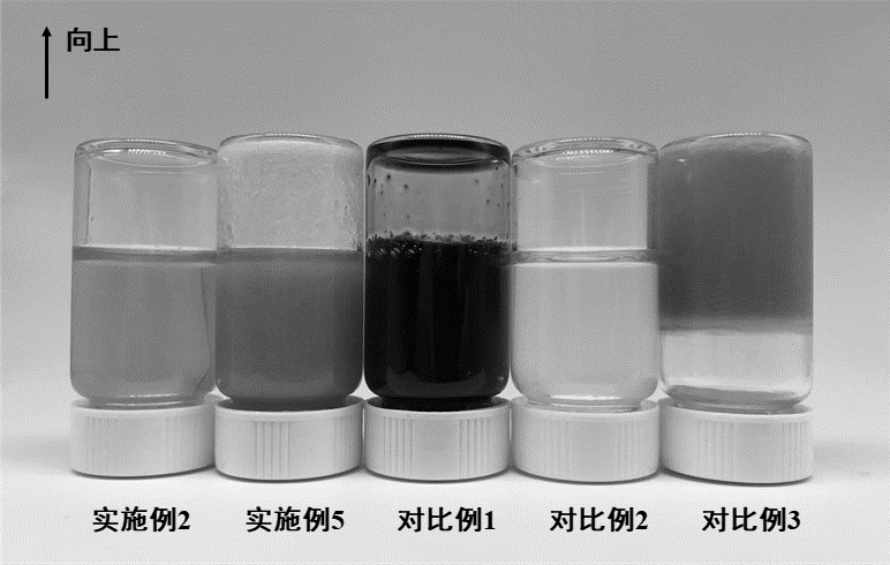

Image

Examples

Embodiment 1

[0036] A kind of preparation of bio-based amino resin retanning agent:

[0037] According to the ratio of parts by weight, take 100 parts of aldehydized starch with a mass concentration of 8%, add it under stirring, then add 5 parts of dicyandiamide, mix well, heat up to 80 ºC, and then add lye dropwise , adjust the pH of the reaction system to be 4.0, and react for 6 hours to obtain the first mixed solution;

[0038] Add 3 parts of sodium bisulfite and 2 parts of glycine to the first mixed solution, adjust the reaction temperature to 90 ºC, and continue the reaction for 0.5 h to obtain a bio-based amino resin retanning agent.

Embodiment 2

[0040] A kind of preparation of bio-based amino resin retanning agent:

[0041] According to the ratio of parts by weight, take 100 parts of alginate sodium alginate with a mass concentration of 8%, add it under stirring, then add 5 parts of melamine, mix well, heat up to 60 ºC, and then add lye dropwise , adjust the pH of the reaction system to be 6.5, and react for 3 h to obtain the first mixed solution;

[0042] Add 8 parts of sodium sulfite to the first mixed solution, adjust the reaction temperature to 70 ºC, and continue the reaction for 1 h to obtain a bio-based amino resin retanning agent.

Embodiment 3

[0044] A kind of preparation of bio-based amino resin retanning agent:

[0045] According to the proportion by weight, take 100 parts of aldylated methyl glucoside with a mass concentration of 25%, add it under stirring, then add 10 parts of benzomelamine, mix well, heat up to 60 ºC, and then drop Add lye, adjust the pH of the reaction system to 6.0, and react for 4 hours to obtain the first mixed solution;

[0046] Add 4 parts of cysteine and 6 parts of alanine to the first mixed solution, adjust the reaction temperature to 50 ºC, and continue the reaction for 2 h to obtain a bio-based amino resin retanning agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com