Wear-resistant anticorrosive coating and preparation method thereof

A kind of anti-corrosion coating and coating technology, applied in the direction of coating, metal material coating process, fusion spraying, etc., can solve the problems of low production efficiency, environmental pollution, etc., and achieve the improvement of hardness, uniform and dense coating structure, good The effect of resistance to various corrosive media

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

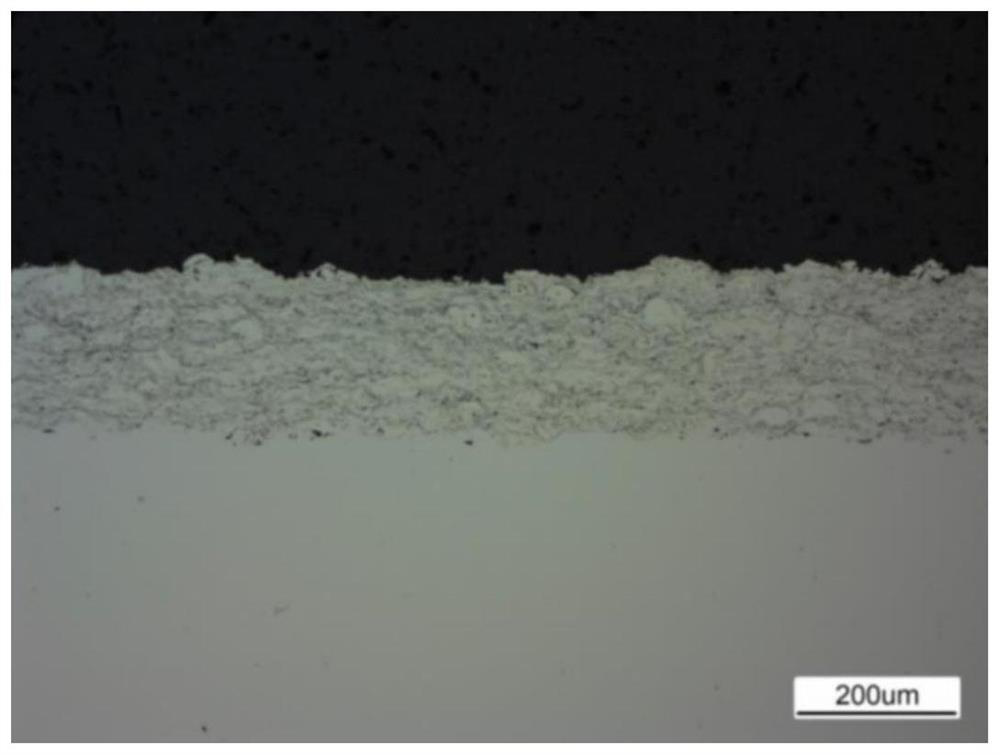

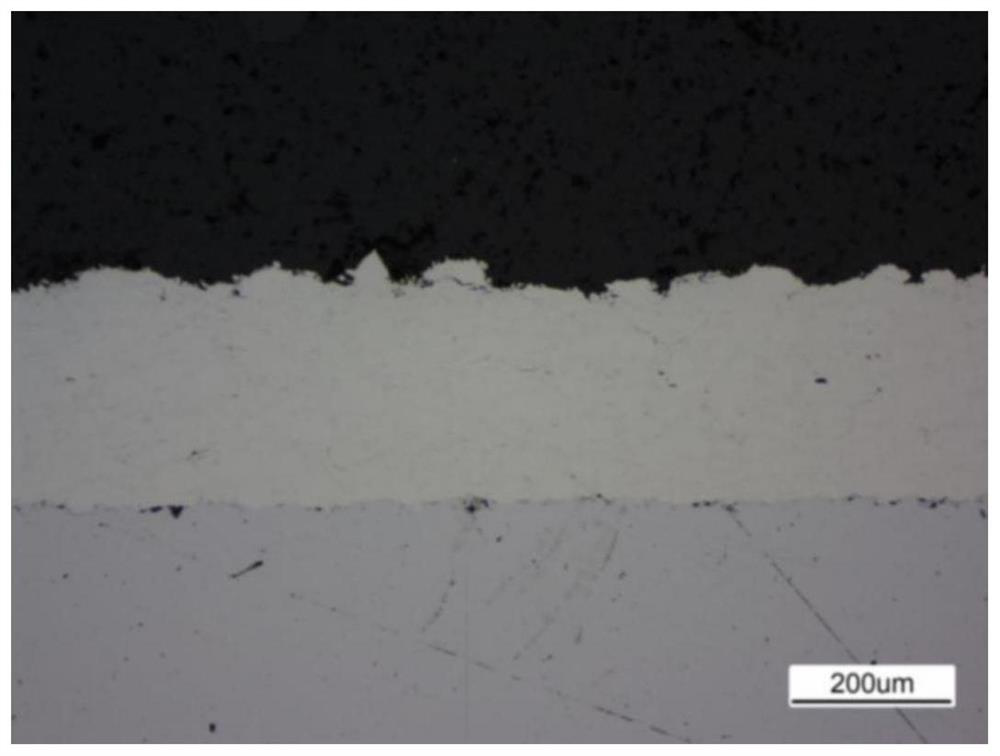

Image

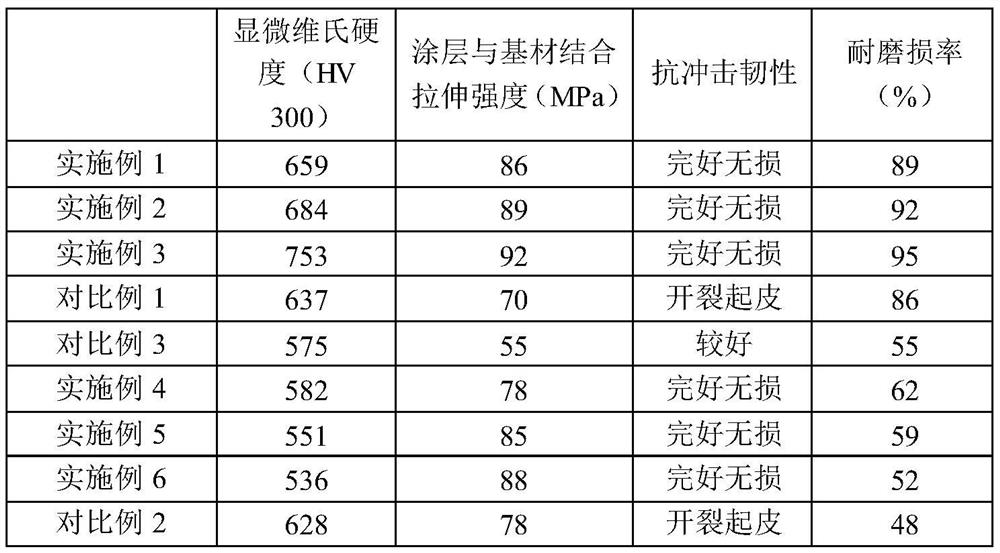

Examples

Embodiment 1

[0032] A wear-resistant and anti-corrosion coating, comprising the following raw materials in weight percentage: 56% nickel, 10% chromium, 12% molybdenum, 12% tungsten, 3% niobium, 6% copper, and 1% boron;

[0033] The preparation method of wear-resistant and anti-corrosion coating is as follows:

[0034] (1) Mix the nickel, chromium, molybdenum, tungsten, niobium, copper, and boron raw material powders of the above formula and use water atomization to make spherical alloy powder with a particle size of 30 μm to 50 μm and a bulk density of about 4.5g / cm 3 ,stand-by;

[0035] (2) Clean the stainless steel base material to be processed by ultrasonic cleaning with acetone and dry it at 80°C, and then perform sandblasting treatment on the surface of the base material. The sandblasting treatment uses compressed air as the power and utilizes high-speed sand flow The impact effect of the substrate is used to roughen the surface of the substrate. The sandblasting material is alumina ...

Embodiment 2

[0037] A wear-resistant and anti-corrosion coating, comprising the following raw materials in weight percentage: 55% nickel, 25% chromium, 6.3% molybdenum, 9.3% tungsten, 1% niobium, 3.2% copper, and 0.2% boron;

[0038]The preparation method of wear-resistant and anti-corrosion coating is as follows:

[0039] (1) Mix the nickel, chromium, molybdenum, tungsten, niobium, copper, and boron raw material powders of the above formula and use water atomization to make spherical alloy powder with a particle size of 30 μm to 50 μm and a bulk density of about 4.5g / cm 3 ,stand-by;

[0040] (2) The stainless steel substrate to be processed is manually wiped clean with alcohol and dried at 50° C., and then the surface of the substrate is subjected to sandblasting treatment. The sandblasting treatment uses compressed air as power and utilizes high-speed sand flow The impact effect of the substrate is used to roughen the surface of the substrate. The sandblasting material is alumina sand, ...

Embodiment 3

[0042] A wear-resistant and anti-corrosion coating, comprising the following raw materials in weight percentage: 52% nickel, 22% chromium, 9.5% molybdenum, 10.5% tungsten, 2% niobium, 3.3% copper, and 0.7% boron;

[0043] The preparation method of wear-resistant and anti-corrosion coating is as follows:

[0044] (1) Mix the nickel, chromium, molybdenum, tungsten, niobium, copper, and boron raw material powders of the above formula and use water atomization to make spherical alloy powder with a particle size of 30 μm to 50 μm and a bulk density of about 4.5g / cm 3 ,stand-by;

[0045] (2) Clean the stainless steel base material to be processed by ultrasonic cleaning with acetone and dry it at 80°C, and then perform sandblasting treatment on the surface of the base material. The sandblasting treatment uses compressed air as the power and utilizes high-speed sand flow The impact effect of the substrate is used to roughen the surface of the substrate. The sandblasting material is a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com