A method for constructing a conductive substrate soft interface, a microelectrode and its application

A conductive substrate, micro-electrode technology, applied in the fields of application, electrolytic organic material coating, medical science, etc., can solve the problems of reducing the electrochemical impedance of electrodes, limiting long-term performance, high time and economic cost, etc., to increase charge storage capacity and The effect of charge injection ability, highly consistent effective surface area, and simple and easy-to-operate construction method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

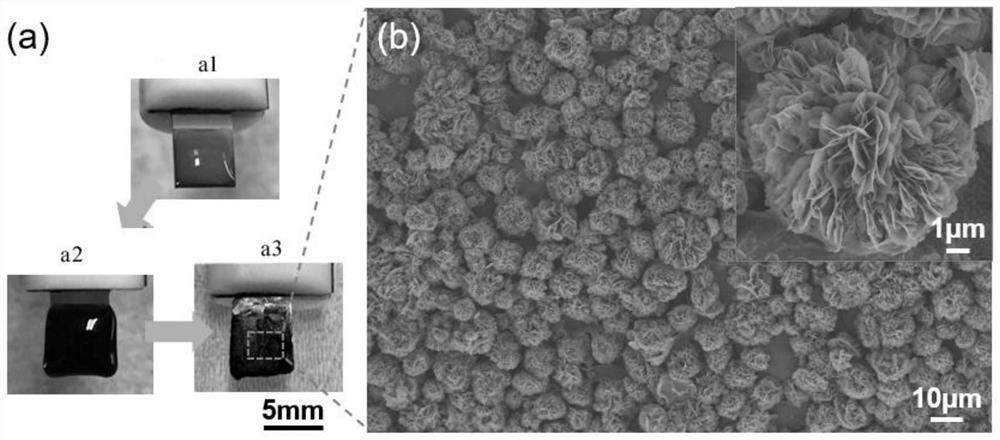

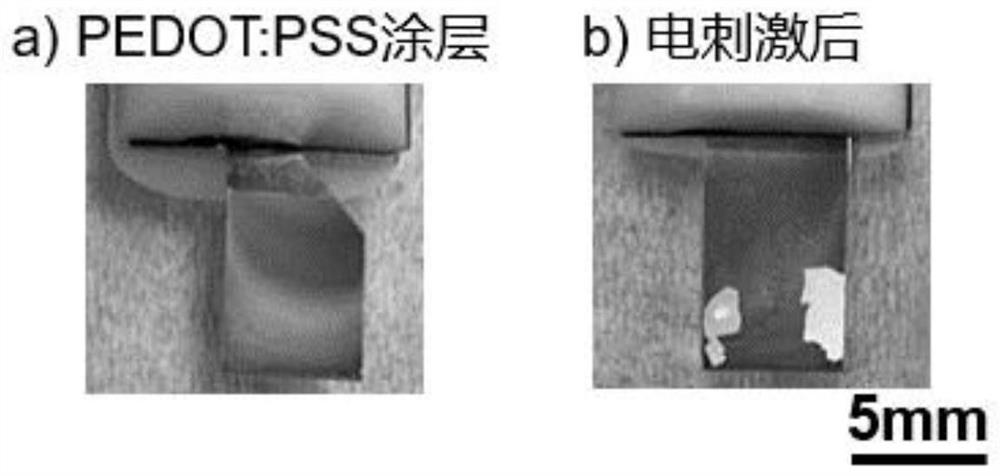

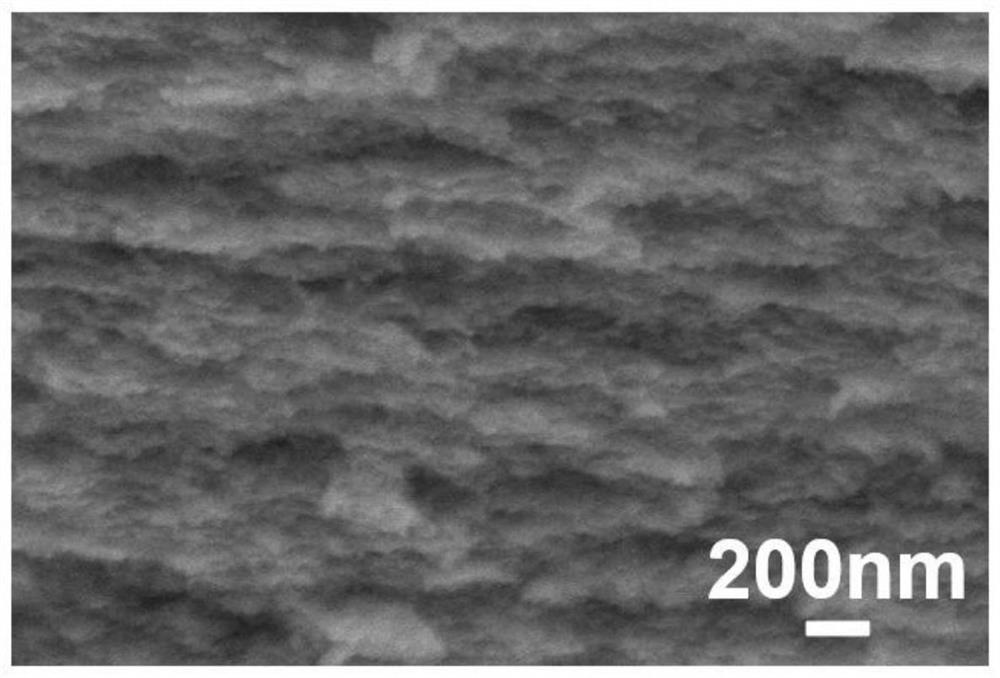

[0035] The present invention exemplarily provides a method for constructing a conductive substrate soft interface, and the method specifically includes the following steps:

[0036] S1. Provide a conductive matrix. Exemplarily, the conductive substrate includes at least one of microelectrode arrays, metal wires, metal sheets, metal rings, conductive plastics and conductive rubbers. Wherein, this embodiment does not limit the size and surface shape of the microelectrode array, metal wire, metal sheet, metal ring, conductive plastic and conductive rubber, that is to say, the surface of the conductive substrate can be flat, curved or other indefinite regular shape.

[0037] S2, forming a sacrificial metal layer on the surface of the conductive substrate. Exemplarily, the metal in the sacrificial metal layer may be copper, magnesium or aluminum, and copper, magnesium or aluminum are cheap and easy to obtain, saving cost.

[0038] S3. Constructing a soft interface on the surface...

Embodiment 2

[0059] The present invention exemplarily provides a microelectrode, comprising a conductive substrate and a soft interface constructed on the conductive substrate, and the soft interface is constructed by the method for constructing a soft interface of a conductive substrate described in Embodiment 1 above.

Embodiment 3

[0061] The present invention exemplarily provides a microelectrode as described in Embodiment 3 in the sensor field, the catalysis field and the neural interface field.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com