Waterproof and radiation-proof fabric and preparation method thereof

A technology of anti-radiation and fabrics, applied in the field of textile fabrics, can solve the problems of further improvement in mechanical properties and poor durability of the waterproof layer, etc., and achieve the effects of remarkable anti-electromagnetic radiation performance, small equipment investment, and high product qualification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

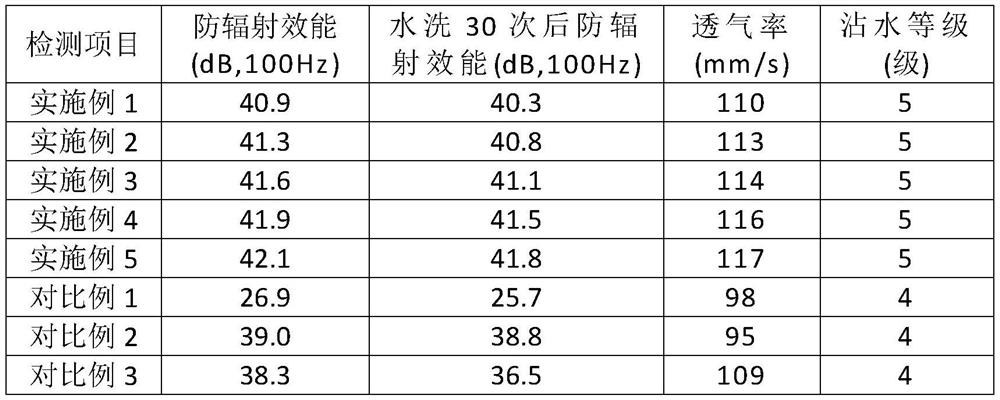

Examples

Embodiment 1

[0034] A waterproof and anti-radiation fabric, which is made of the following components by weight: 10 parts of polythiophene with alcohol amine groups in the side chain, 2,3,5,6-tetrafluoro-terephthalenedimethanol / isocyanate-terminated polyurethane 45 parts of polycondensate, 3 parts of fluorinated graphene modified by isocyanate propyltriethoxysilane, and 1 part of triethylamine.

[0035] The 2,3,5,6-tetrafluoro-tere-phenylenedimethanol / isocyanate-terminated polyurethane prepolymer polycondensate is prepared by the following steps: adding the vacuum-dehydrated isocyanate-terminated flask to a three-necked flask with a stirring device Add the base polyurethane prepolymer, 2,3,5,6-tetrafluoro-tere-phenylenedimethanol and the catalyst into the high-boiling point solvent, stir and react at 85°C for 9 hours under an inert gas atmosphere, and then add the end-capping agent to it, Continue to keep warm and stir to react for 1 hour. After the reaction is completed, the solvent is re...

Embodiment 2

[0043] A waterproof and radiation-proof fabric, which is made of the following components by weight: 12 parts of polythiophene with alcohol amine groups in the side chain, 2,3,5,6-tetrafluoro-terephthalenedimethanol / isocyanate-terminated polyurethane 50 parts of polycondensate, 3.5 parts of fluorinated graphene modified by isocyanate propyltriethoxysilane, and 1.5 parts of triethylamine.

[0044] The 2,3,5,6-tetrafluoro-tere-phenylenedimethanol / isocyanate-terminated polyurethane prepolymer polycondensate is prepared by the following steps: adding the vacuum-dehydrated isocyanate-terminated flask to a three-necked flask with a stirring device Add the base polyurethane prepolymer, 2,3,5,6-tetrafluoro-tere-phenylenedimethanol and the catalyst into the high-boiling point solvent, stir and react at 87°C for 10 hours under an inert gas atmosphere, and then add the end-capping agent to it, Continue to heat and stir the reaction for 1.2 hours. After the reaction is completed, the solv...

Embodiment 3

[0052] A waterproof and anti-radiation fabric, made of the following components by weight: 13 parts of polythiophene with alcohol amine groups in the side chain, 2,3,5,6-tetrafluoro-terephthalenedimethanol / isocyanate-terminated polyurethane 55 parts of polycondensate, 4 parts of fluorinated graphene modified by isocyanate propyltriethoxysilane, and 2 parts of triethylamine.

[0053] The 2,3,5,6-tetrafluoro-tere-phenylenedimethanol / isocyanate-terminated polyurethane prepolymer polycondensate is prepared by the following steps: adding the vacuum-dehydrated isocyanate-terminated flask to a three-necked flask with a stirring device Add the base polyurethane prepolymer, 2,3,5,6-tetrafluoro-tere-phenylenedimethanol and the catalyst into the high-boiling solvent, stir and react at 90°C for 11 hours under an inert gas atmosphere, and then add the end-capping agent to it, Continue to heat and stir the reaction for 1.5 hours. After the reaction is completed, the solvent is removed by ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com