Preparation method of moisture-absorbing breathable bottom film

A moisture-absorbing, breathable, bottom film technology, which is applied in the manufacture of rayon, liquid-repellent fibers, and artificial filaments made of viscose, etc., can solve the risk of urine leakage, damp diapers, and breathable membranes To achieve the effect of mild conditions, dry surface and soft hand feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

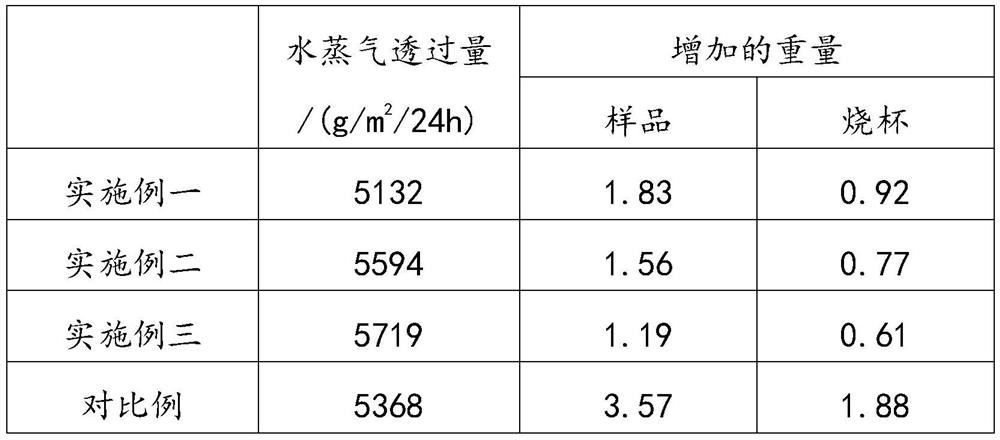

Examples

Embodiment 1

[0039]A method of preparing a moisture absorbent and breathable background, including the following steps:

[0040]a. Preparation of modified viscose fibers

[0041]With cellulose pulp as raw materials, impregnated, press, crush, aging, yellowing, dissolving, and cooked formation of viscose spinning fiber, add microcapsule finishing liquid to viscose fiber spinning liquid, high-speed agitation Defoulating, then obtaining a primary shade by wet spinning, the primary silk bundle was cut off after drafting, post-treatment, and obtained modified viscose fibers;

[0042]The microcapsule finishing solution is prepared by following:

[0043](1) 1 kg of chitosan is added to a 5% acetic acid solution, and the chromorative treatment of 30 min, obtains the chitosanaceous acetate solution, the mass ratio of chitosan and acetic acid solution is 1:50;

[0044](2) 1 kg of Arabic is dissolved in 60 ° C deionized water, the mass ratio of the gum and deionized water is 1:50, and then 1.4 kg composite essential oil ...

Embodiment 2

[0059]A method of preparing a moisture absorbent and breathable background, including the following steps:

[0060]a. Preparation of modified viscose fibers

[0061]With cellulose pulp as raw materials, impregnated, press, crush, aging, yellowing, dissolving, and cooked formation of viscose spinning fiber, add microcapsule finishing liquid to viscose fiber spinning liquid, high-speed agitation Defoulating, then obtaining a primary shade by wet spinning, the primary silk bundle was cut off after drafting, post-treatment, and obtained modified viscose fibers;

[0062]The microcapsule finishing solution is prepared by following:

[0063](1) 1.5 kg chitosan is added to 8% acetic acid solution, and 45 min is ultrasonic treatment to obtain a chitosanaceous acetate solution, and the mass ratio of chitosan and acetic acid solution is 1:50;

[0064](2) 1 kg of Arabic is dissolved in the deionized water of 65 ° C, the mass ratio of the Arabic gum and the deionized water is 1: 50, and 2 kg composite essentia...

Embodiment 3

[0079]A method of preparing a moisture absorbent and breathable background, including the following steps:

[0080]a. Preparation of modified viscose fibers

[0081]With cellulose pulp as raw materials, impregnated, press, crush, aging, yellowing, dissolving, and cooked formation of viscose spinning fiber, add microcapsule finishing liquid to viscose fiber spinning liquid, high-speed agitation Defoulating, then obtaining a primary shade by wet spinning, the primary silk bundle was cut off after drafting, post-treatment, and obtained modified viscose fibers;

[0082]The microcapsule finishing solution is prepared by following:

[0083](1) 2 kg chitosan is added to a 10% acetic acid solution, and 60 min is tested for 60 min to obtain a chitosanacrocetan acid solution, and the mass ratio of chitosan and acetic acid solution is 1: 50;

[0084](2) 1 kg of Arabic is dissolved in 70 ° C deionized water, and the mass ratio of the gum and deionized water is 1:50, then the 3kg composite essential oil and 0....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com