N-type monocrystalline silicon HBC solar cell structure and preparation method thereof

A technology for solar cells and monocrystalline silicon, applied in circuits, electrical components, photovoltaic power generation, etc., can solve problems such as high production costs and difficult manufacturing processes, reduce minority carrier recombination, improve passivation effects and anti-reflection effects, and increase The effect of n+ front field area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

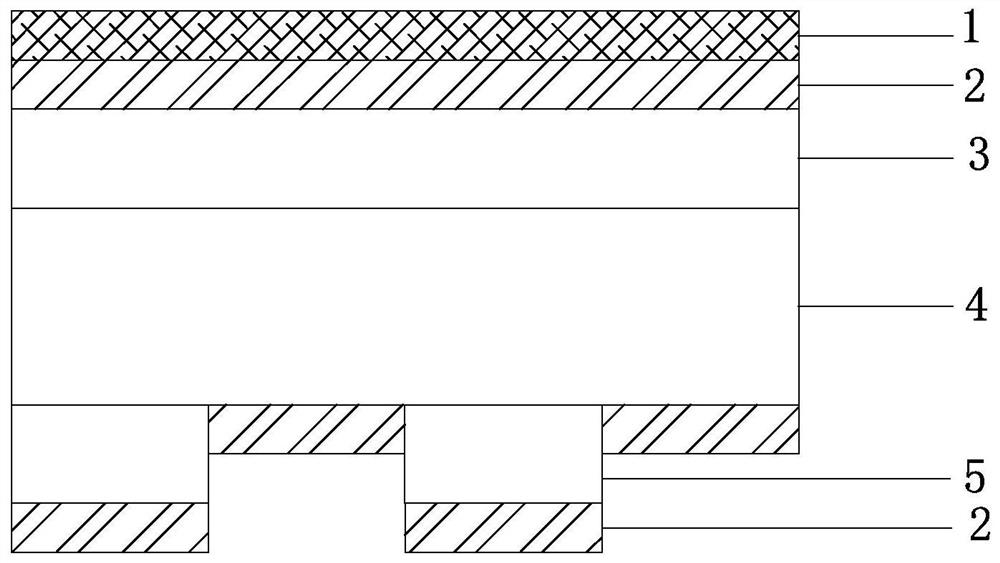

[0055] The preparation method of the above-mentioned N-type monocrystalline silicon HBC solar cell structure of the present invention comprises the following steps:

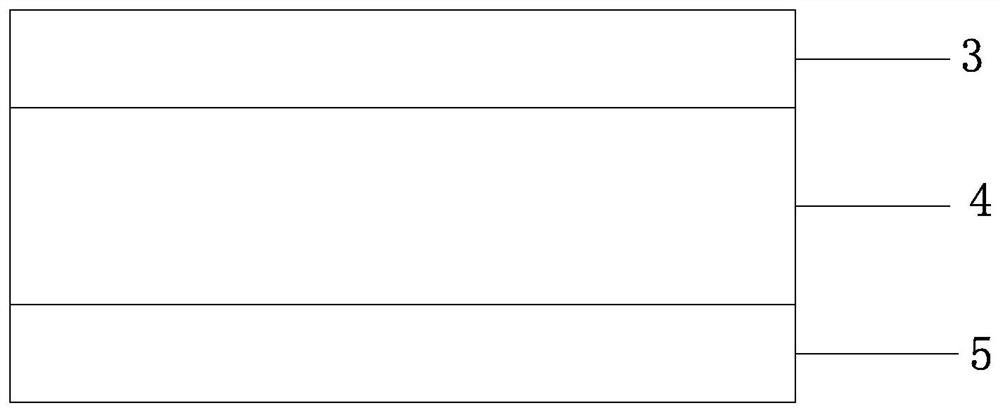

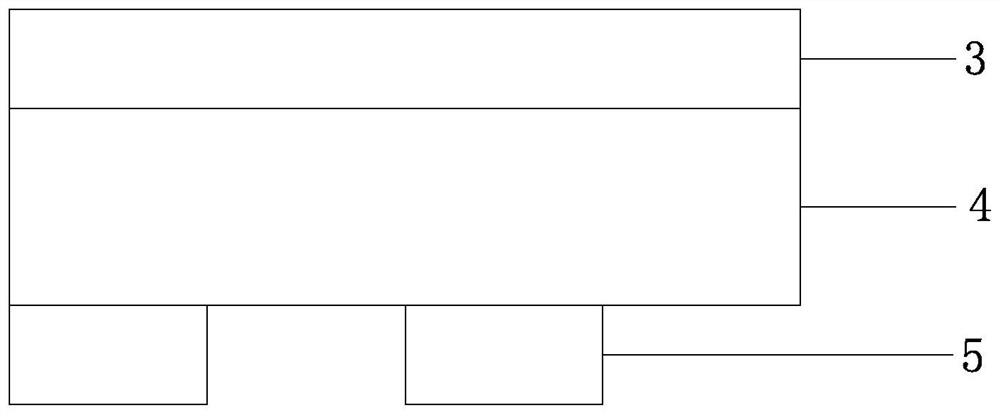

[0056] Step (1): Select an N-type single crystal silicon wafer, use the existing conventional method to carry out texturing on the front and polishing on the back to obtain a silicon wafer with a front reflectivity of 9%-15% and back polishing, and the obtained silicon wafer is The single crystal silicon substrate 4 of the battery; the polishing technology adopts chemical liquid polishing, and physical polishing can also be used;

[0057] Step (2): Place the silicon wafer obtained in step (1) in a furnace tube at 950°C for boron diffusion. The silicon wafers are placed face to face, and the diffusion time is 65 minutes. The diffusion time can also be selected within the range of 60-70 minutes , diffused on the back of the silicon wafer to form a p+-type crystalline silicon layer 5, with a diffusion square resista...

Embodiment 2

[0074] The preparation method of the above-mentioned N-type monocrystalline silicon HBC solar cell structure of the present invention comprises the following steps:

[0075] Step (1): Select an N-type single crystal silicon wafer, use the existing conventional method to carry out texturing on the front and polishing on the back to obtain a silicon wafer with a front reflectivity of 9%-15% and back polishing, and the obtained silicon wafer is The monocrystalline silicon substrate 4 of the battery;

[0076] Step (2): place the silicon wafer obtained in step (1) in a furnace tube at 950°C for boron diffusion, place the silicon wafers face to face, and diffuse for 70 minutes to form a p+ type crystalline silicon layer 5 on the back of the silicon wafer. Diffusion square resistance 150Ω±10Ω;

[0077] Step (3): Place the silicon wafer obtained in step (2) in a furnace tube at 850°C for boron diffusion. The silicon wafers are placed back to back, and the diffusion time is 70 minutes...

Embodiment 3

[0092] The preparation method of the above-mentioned N-type monocrystalline silicon HBC solar cell structure of the present invention comprises the following steps:

[0093] Step (1): Select an N-type single crystal silicon wafer, use the existing conventional method to carry out texturing on the front and polishing on the back to obtain a silicon wafer with a front reflectivity of 9%-15% and back polishing, and the obtained silicon wafer is The single crystal silicon substrate 4 of the battery; the polishing technology adopts chemical liquid polishing, and physical polishing can also be used;

[0094] Step (2): Place the silicon wafer obtained in step (1) in a furnace tube at 950°C for boron diffusion. The silicon wafers are placed face to face, and the diffusion time is 65 minutes. The diffusion time can also be selected within the range of 60-70 minutes , diffused on the back of the silicon wafer to form a p+-type crystalline silicon layer 5, with a diffusion square resista...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com