Method for synthesizing high-efficiency adsorbent by using low-grade magnesite through one-pot method

An adsorbent and magnesite technology, applied in the field of adsorbent materials, can solve the problems of limiting the application of magnesite and increasing the cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

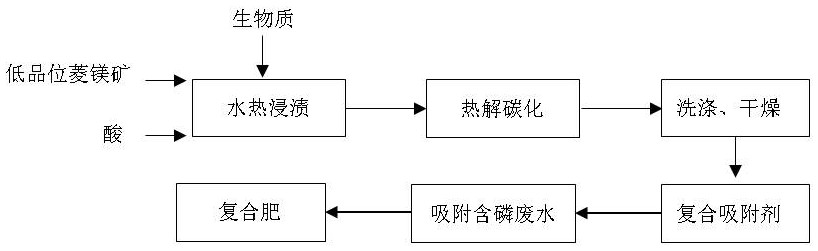

Method used

Image

Examples

Embodiment 1

[0020] (1) Impregnation: Use nitric acid solution to react with 88g of low-grade magnesite powder, control pH=7 to obtain a turbid solution, add 120g of crushed peanut shells to the turbid solution, and immerse at 25°C for 8 hours;

[0021] (2) Water removal: the mixture was further dried in an oven at 80°C to remove water, and the precursor was obtained for future use.

[0022] (3) Pyrolysis: the obtained precursor is placed in a 550°C atmosphere furnace for high temperature treatment for 2 hours;

[0023] (4) Washing: After the material drops to room temperature, wash with deionized water to remove impurities;

[0024] (5) Drying: Remove moisture in a drying oven at 120°C to obtain a composite adsorbent.

[0025] Take 0.1g composite adsorbent for adsorption of 300mg / L, 200mL potassium dihydrogen phosphate-containing solution adsorption, the adsorption capacity of potassium dihydrogen phosphate is 580mg P / g, after adsorption, the adsorbent is filtered, dried and then applied...

Embodiment 2

[0027] (1) Impregnation: use sulfuric acid solution to react with 88g of low-grade magnesite powder, control the pH=6.5 to obtain a turbid solution, add 100g of crushed peanut shells to the turbid solution, and immerse at 25°C for 8 hours;

[0028] (2) Dehydration: the mixture is further dried in an oven at 90°C to remove moisture to obtain a precursor for later use.

[0029] (3) Pyrolysis: the obtained precursor is placed in a 600°C atmosphere furnace for high temperature treatment for 1.5 hours;

[0030] (4) Washing: After the material drops to room temperature, wash with deionized water to remove impurities;

[0031] (5) Drying: Remove moisture in a drying oven at 120°C to obtain a composite adsorbent.

[0032] The composite adsorbent is used to adsorb 300mg / L and 200mL potassium dihydrogen phosphate solution, and the adsorption capacity of potassium dihydrogen phosphate is 563mg P / g. After adsorption, the adsorbent is filtered, dried and then applied to soybean crops. Co...

Embodiment 3

[0034] (1) Impregnation: Use nitric acid solution to react with 88g of low-grade magnesite powder, control pH = 8 to obtain a cloudy solution, add 100g of crushed peanut shells to the cloudy solution, and soak at 25°C for 8 hours;

[0035] (2) Water removal: the mixture was further dried in an oven at 150°C to remove water to obtain a precursor for later use.

[0036] (3) Pyrolysis: the obtained precursor is placed in an 800°C atmosphere furnace for high temperature treatment for 3 hours;

[0037] (4) Washing: After the material drops to room temperature, wash with deionized water to remove impurities;

[0038] (5) Drying: Remove moisture in a drying oven at 120°C to obtain a composite adsorbent.

[0039] The composite adsorbent is used to adsorb 300mg / L and 200mL potassium dihydrogen phosphate solution, and the adsorption capacity of potassium dihydrogen phosphate is 532mg P / g. After adsorption, the adsorbent is filtered, dried and then applied to soybean crops. Compared wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com