Acehytisine freeze-drying emulsion and reparation method thereof

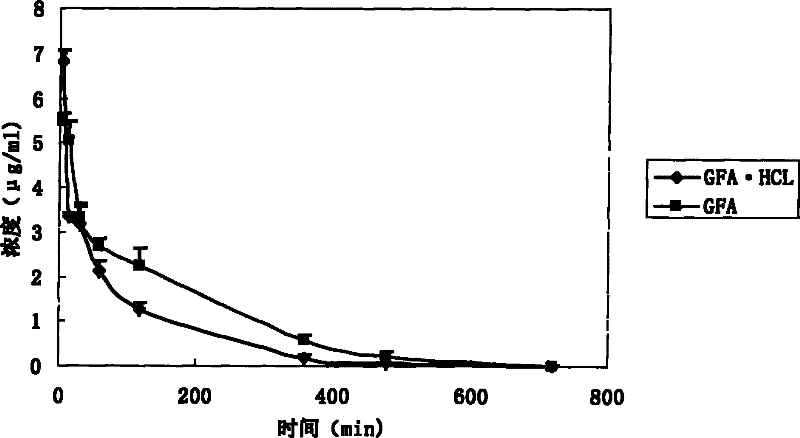

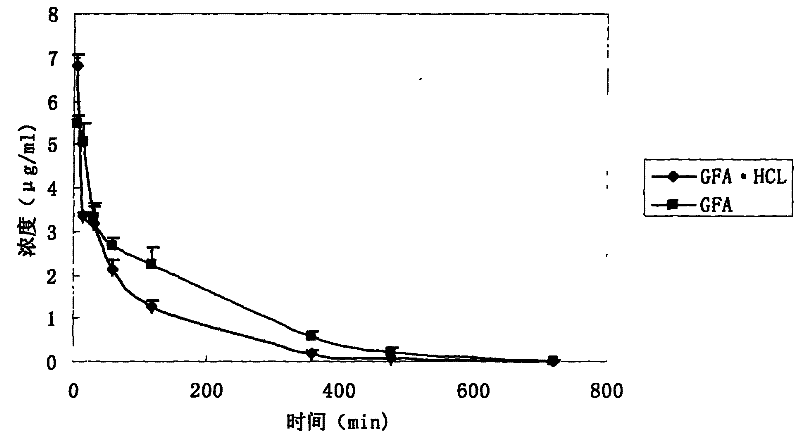

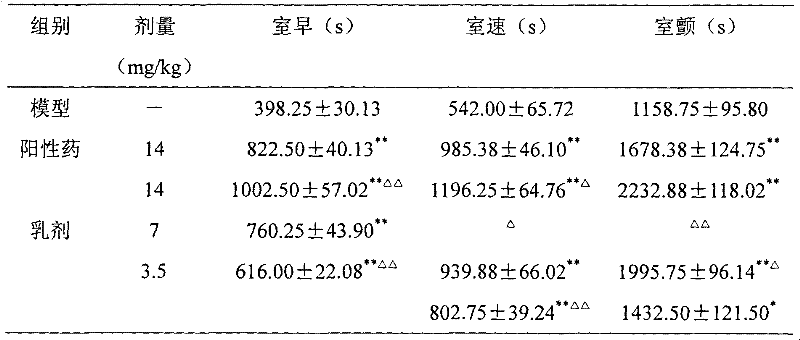

A technology of Guanfu A and freeze-dried emulsion, which is applied in the field of Guanfu A freeze-dried emulsion and its preparation, to achieve the effects of prolonging circulation time, reducing drug dosage and high pharmacological activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Dissolve 0.05 part of Guanfu A in 0.8 part of soybean oil for injection as the oil phase; 0.2 part of soybean lecithin, 0.001 part of vitamin C, 0.125 part of glycerin and 0.25 part of mannitol are dissolved in water for injection; add the oil phase to water In the phase, after high-speed dispersion at 8,000 rpm, the first-stage valve is 1,000 bar, and the second-stage valve is 150 bar high-pressure homogenization to obtain a uniformly dispersed emulsion; after filtration sterilization, pre-freeze at -20°C for 8 hours, and then heat up at a rate of 0.5°C / min Freeze-dried for 12 hours to obtain. After reconstitution into a liquid emulsion, the particle size is between 300-400nm.

Embodiment 2

[0047] Dissolve 0.07 part of Guanfu A in 1 part of medium-chain fatty acid for injection as the oil phase; 0.12 part of soybean lecithin, 0.2 part of poloxamer F-68, 0.005 part of L-cysteine and 0.5 part of glucose In water for injection; add the oil phase to the water phase and disperse at a high speed of 10,000 rpm, and then homogenize at a high pressure of 1500 bar with the first stage valve and 300 bar with the second stage valve to obtain a uniformly dispersed emulsion; after filter sterilization, pre-freeze at -40°C for 12 hours Afterwards, freeze-dry at a rate of 0.3°C / min for 24 hours to obtain the product. After reconstitution into a liquid emulsion, the particle size is between 300-400nm.

Embodiment 3

[0049] Dissolve 0.1 part of Guanfu A in a mixed oil of 0.5 part of soybean oil for injection and 0.5 part of medium-chain fatty acid as the oil phase; 0.1 part of lecithin, 0.15 part of poloxamer F-68, 0.01 part of anhydrous sodium sulfite , 0.12 parts of glycerin and 0.3 parts of sorbitol are dissolved in water for injection; after the oil phase is added to the water phase to disperse at a high speed of 9000 rpm, the first-stage valve is 1300 bar, and the second-stage valve is 200 bar high-pressure homogenization to obtain a uniformly dispersed emulsion; After sterilizing, pre-freeze at -30°C for 10 hours, then freeze-dry at a rate of 0.15°C / min for 20 hours to obtain the product. After reconstitution into liquid emulsion, the particle diameter is between 300-400nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com