Composite modified asphalt and preparation method thereof

A technology of compound modified asphalt and bitumen, applied in building components, building insulation materials, buildings, etc., can solve the problems of reducing the high and low temperature performance of rubber asphalt, application limitations, and high SBS price, and achieves improved compatibility and comprehensive performance. , Improve the effect of high and low temperature performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

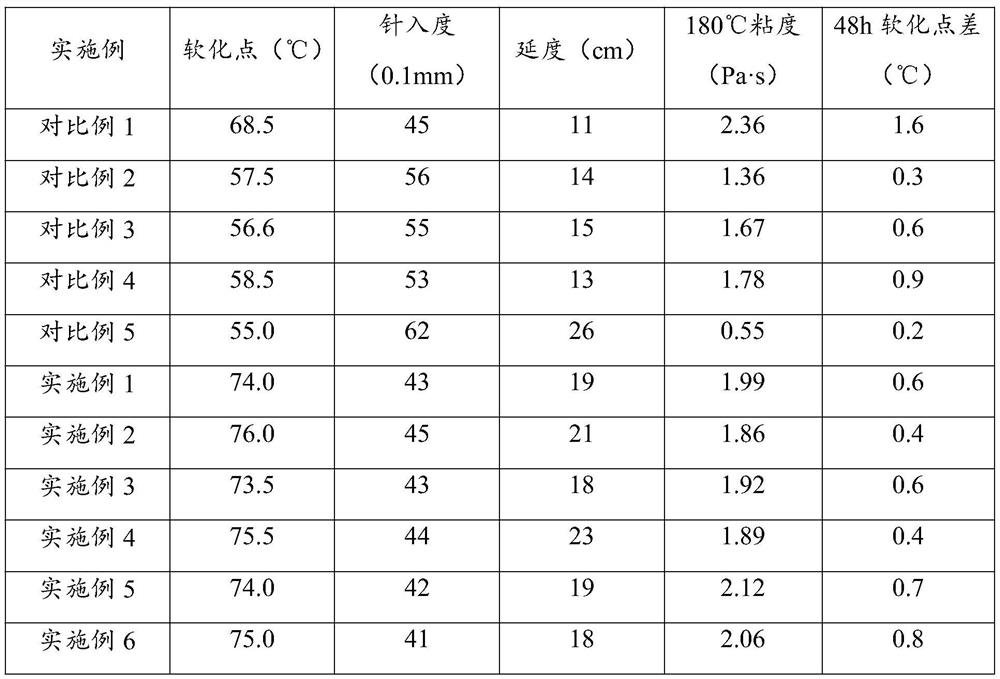

Examples

preparation example Construction

[0043] The present invention also provides a preparation method of the composite modified asphalt described in the above technical scheme, comprising the following steps:

[0044] Swelling after mixing the base asphalt with SBS, stabilizer and anti-aging agent in sequence to obtain swollen asphalt;

[0045] Shearing and developing the swelled asphalt in sequence to obtain developed asphalt;

[0046] The developed asphalt is mixed with the activated rubber powder and the solubilizer in sequence, and then sheared and developed in sequence to obtain the composite modified asphalt.

[0047] In the invention, the matrix asphalt is mixed with SBS, stabilizer and anti-aging agent in sequence, and then swelled to obtain swollen asphalt.

[0048] In the present invention, the base asphalt is preferably placed in an oven at 140-150°C and heated to a fluid state, taken out and placed on a heating device, and then SBS, stabilizer and anti-aging agent are sequentially added under stirring...

Embodiment 1

[0086] Embodiment 1: Activated rubber powder (twin-screw extrusion granulation method) / SBS composite modified asphalt

[0087] The activated rubber powder / SBS composite modified asphalt given in this embodiment is composed of the following raw materials in parts by weight: base asphalt (Maoming 70# base asphalt, softening point is 46 ° C, and penetration at 25 ° C is 70 (0.1 mm), 15°C ductility of 160cm) 79 parts, activated rubber powder 18 parts, SBS (1301 type SBS, produced by Sinopec Baling Petrochemical Company, S / B block ratio is 30:70, non-oil-extended product , molecular weight is 80,000~100,000) 1.5 parts, stabilizer (anhydrous calcium chloride, analytically pure, fineness is 800 mesh~1000 mesh) 0.5 part, solubilizer (the furfural extract oil produced by Hebei Hengshui Diyi Petroleum Company , specific gravity is 0.989-0.995, flash point is 250°C-260°C) 0.5 part and anti-aging agent (anti-aging agent 4010NA, specific gravity is 1.29-1.33, melting point is 100°C-110°C) ...

Embodiment 2

[0099] Embodiment 2: Activated rubber powder (twin-screw extrusion granulation method) / SBS composite modified asphalt

[0100] The difference between this embodiment and the above-mentioned embodiment 1 lies in the ratio of each raw material. The activated rubber powder / SBS composite modified asphalt that present embodiment provides is made up of following raw materials in parts by weight: 80 parts of base asphalt, 16.5 parts of activated rubber powder, 2 parts of SBS, 0.5 part of stabilizer, 0.5 part of solubilizer and 0.5 part of anti-aging agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com