Transformer production process

A production process and transformer technology, applied in the direction of inductance/transformer/magnet manufacturing, electrical components, circuits, etc., can solve the problems of increasing the labor intensity of operators, and achieve the effect of easy maintenance and lightening rigid contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

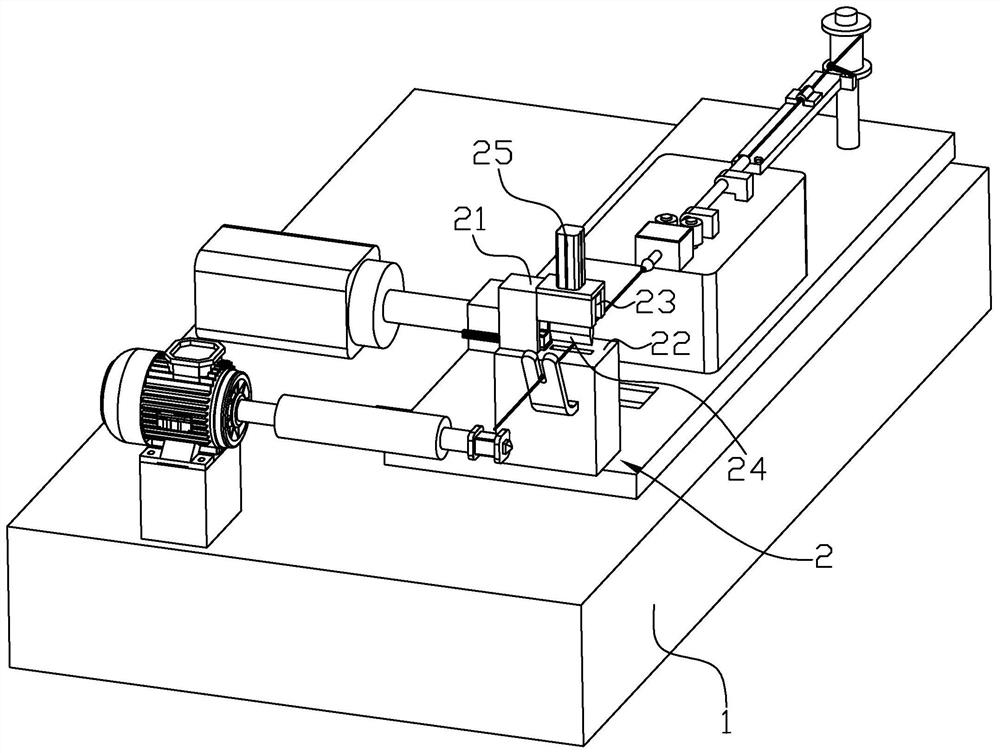

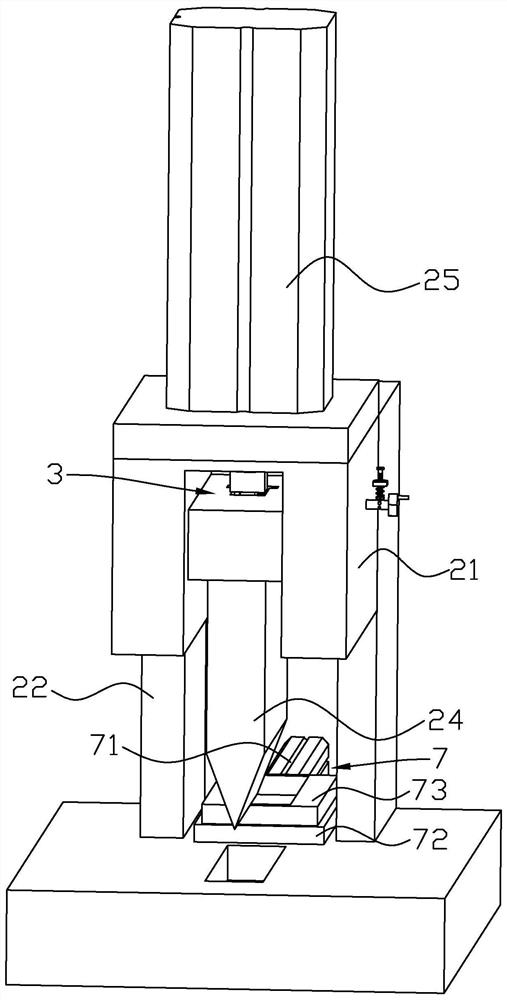

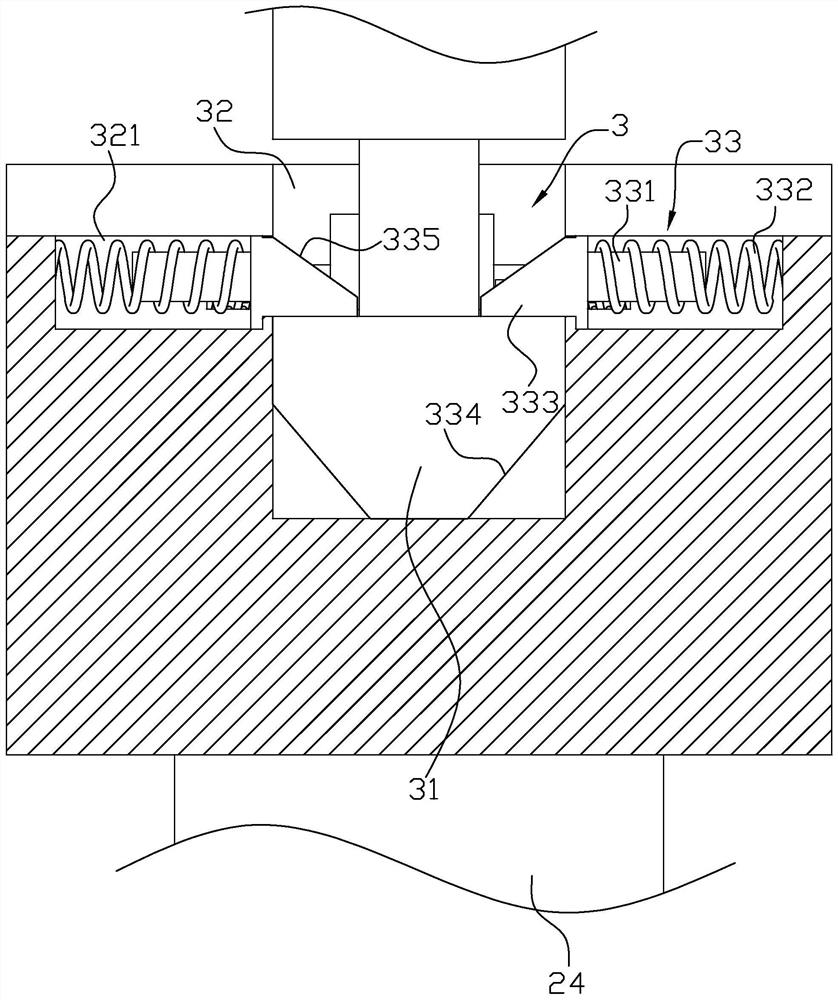

[0038] Embodiment: a kind of transformer production technique, as figure 1 and figure 2 As shown, including: S1, preparation process; S2, winding Ⅰ; S3, winding Ⅱ; S4, glue wrapping; S5, shaping glue wrapping; S6, wire cutting and stripping paint; S7, iron core assembly; High voltage; S9, bundled steel strip, measuring inductance high voltage; S10, appearance inspection, vacuum impregnation; S11, wire trimming, paint stripping, tinning; S12, lead wire twisting; S13, lead wire welding, encapsulation; S14, broken wire, Heat-shrinkable sleeve, wire binding; S15, QC electrical test; S16, paste model logo; S17, appearance inspection; S18, packaging; step S2: first press the reset button of the winding machine, and then make the copper wire pass through the winding machine in turn wire wheel, wire breaking device 2 and winding device; next, the copper wire is wound on the bobbin by the winding device, and when the copper wire on the bobbin is wound to completion, the copper wire i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com