Trench gate type IGBT structure

A trench gate, trench gate technology, applied in semiconductor devices, electrical components, circuits, etc., can solve the problems of trench gate IGBT voltage drop, large transmission capacitance, and large device loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to better understand the present invention, the content of the present invention will be further described below in conjunction with the accompanying drawings and examples.

[0037] In order to overcome the structural defects of existing chips, the invention provides a trench gate IGBT structure.

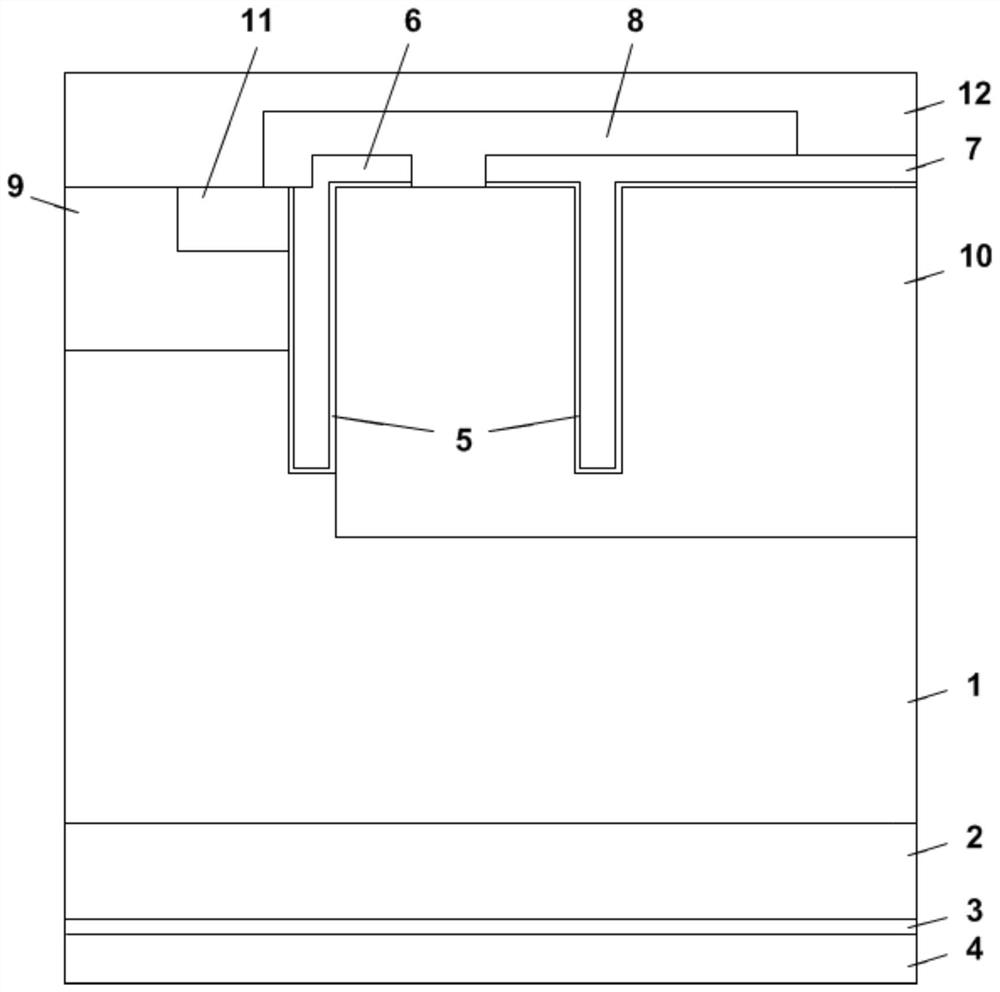

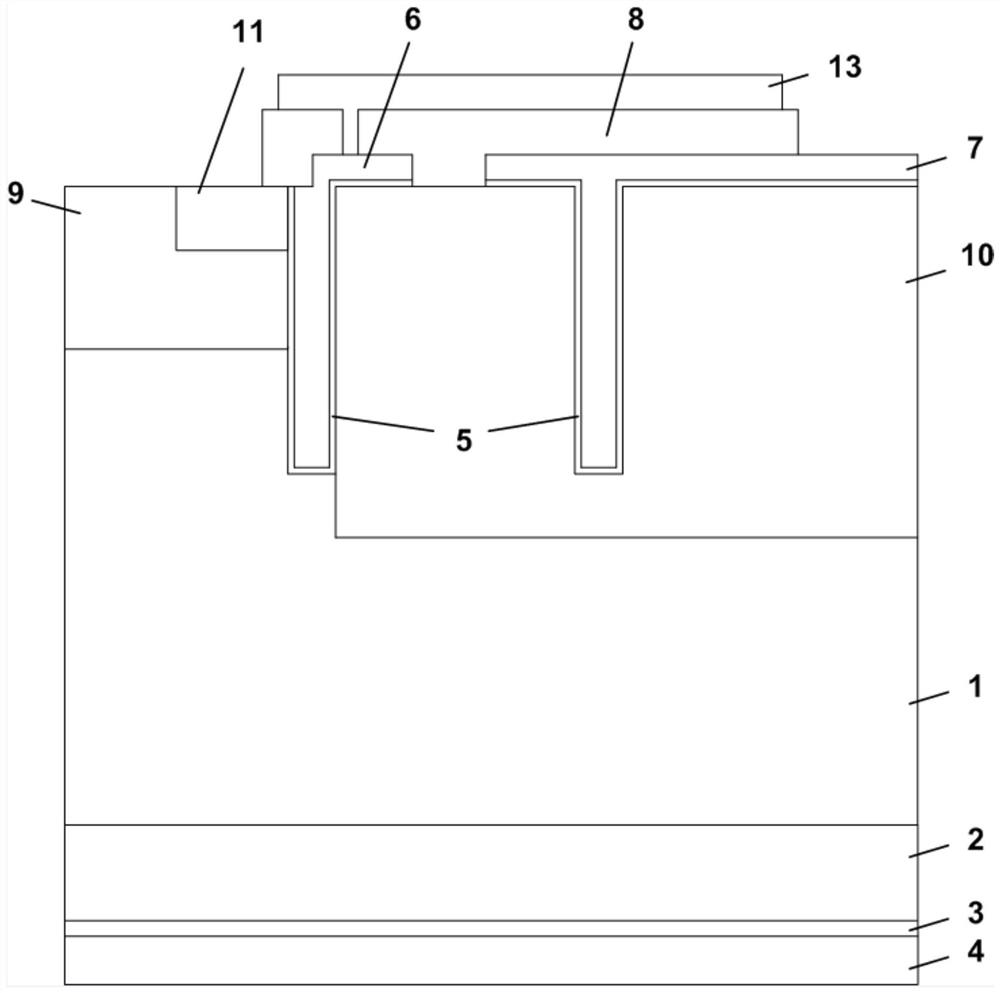

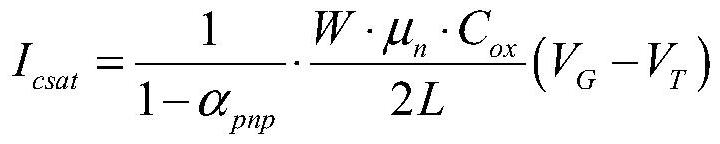

[0038] Such as figure 1 and figure 2 As shown, compared with the ordinary trench gate IGBT chip, this structure separates the gate polycrystalline etching isolation outside the trench to form two parts, the polysilicon trench gate structure 6 and the polysilicon dummy gate structure 7, in which the polysilicon The polysilicon in the trench of the dummy gate structure 7 is not connected to the external electrode to form a dummy gate, and at the same time, the isolation oxide layer 8 is isolated from oxygen and etched to form a contact hole, and the polysilicon dummy gate structure 7 is connected to the N-type dummy gate structure 7 through the front metal electrode ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com