Sensorless control method for high-speed permanent magnet synchronous motor

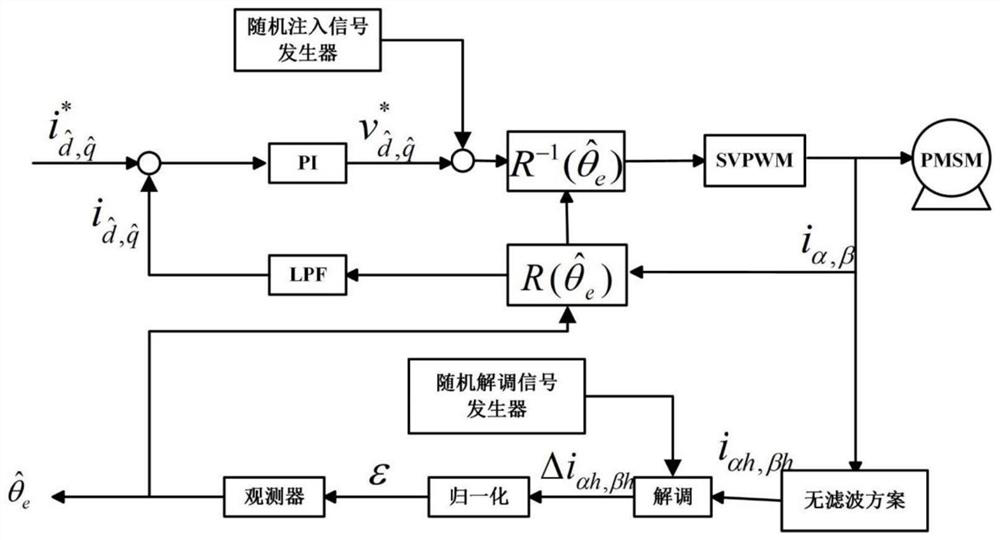

A technology of permanent magnet synchronous motor and control method, applied in motor control, motor generator control, electronic commutation motor control and other directions, can solve the problems of affecting the dynamic performance of the system, difficulty in implementation, and inaccuracy, and reduce inverter nonlinear effects of the device, avoid the system bandwidth limitation, and broaden the power spectral density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0170] In the present invention, the random square wave signal injection used has a more significant effect on reducing the noise of the permanent magnet synchronous motor than the fixed frequency frequency signal injection, as follows:

[0171] 1) Spectrum diagram of motor current injected by fixed frequency square wave signal

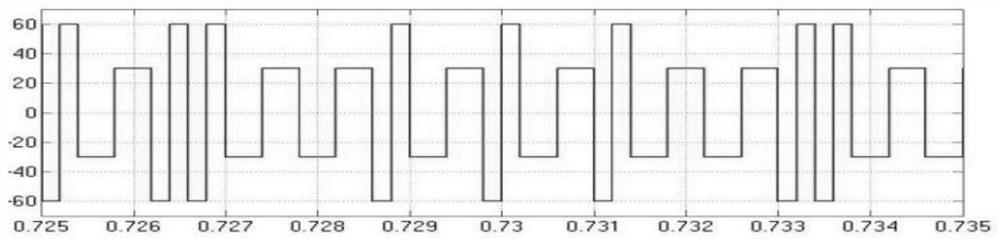

[0172] inject as Figure 12 The fixed frequency square wave signal shown is a square wave signal with a square wave amplitude of 60V, a frequency of 2.5kHz, and a period T of 0.004s.

[0173] According to formula (15), the discrete spectral density can be obtained,

[0174]

[0175] Calculated by the above formula, the motor current spectrum diagram is as follows: Figure 14 As shown in (a), there are obvious peaks in the motor current spectrogram, and their amplitudes are: 7.2dB, -0.1dB, -6.2dB; the peaks of the motor current spectrogram represent noise. The larger the amplitude of the spike, the correspondingly larger the noise.

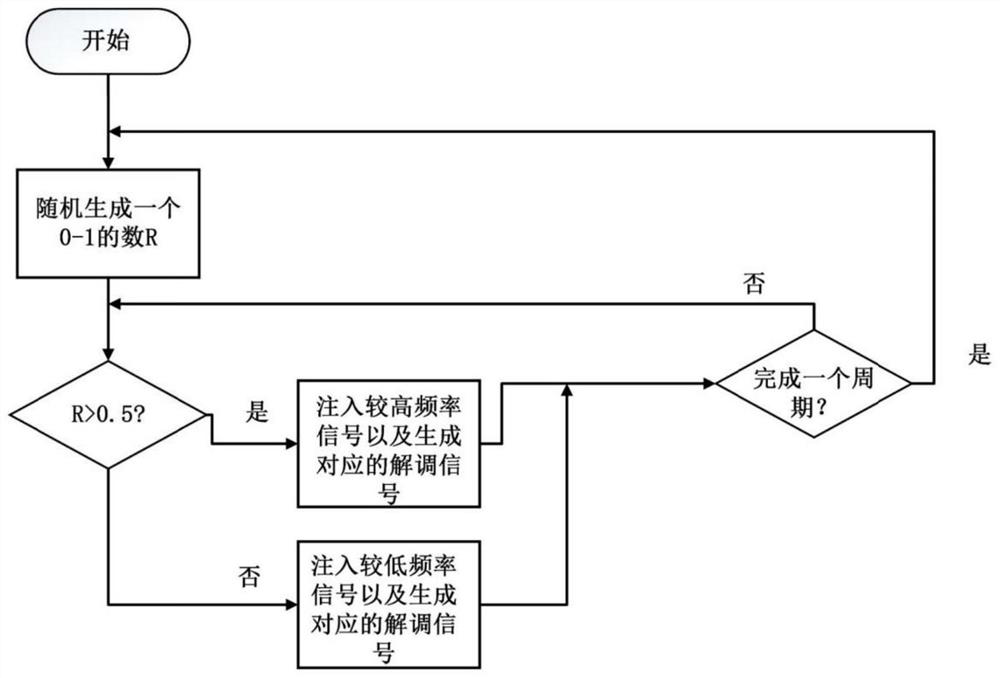

[0176] 2) S...

Embodiment 2

[0184] In another preferred embodiment of the present invention, due to the nonlinearity of the inverter, the actual high-frequency voltage signal is distorted. Taking the d-axis as an example, the d-axis appears as δu dh voltage error, so that the injected voltage Step-like, resulting in induced current produce non-linear effects such as Figure 15 (a) shown.

[0185] Therefore, based on Figure 6 The principle of the high-frequency injection method for real-time adjustment of the amplitude shown in the figure, K in the figure ph is the proportional coefficient of the PI regulator; K ih is the integral coefficient; Tsamp is the sampling time; z is the discretization operator; the error is eliminated by constructing the regulator, as shown in the following formula (29):

[0186]

[0187] In the formula, Indicates the error between the actual angle and the estimated angle; Δi qh Indicates the change value of the q-axis current; Δi dh Indicates the d-axis current c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com