Polyethylene composition for films

A technology of composition and polyethylene, which is applied in the field of multi-stage polymerization for the preparation of polyethylene composition and the preparation of blown film, can solve the problems of deterioration of processing performance, insufficient balance of dart impact strength and machinability, etc., and achieve high Effect of Mechanical Properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

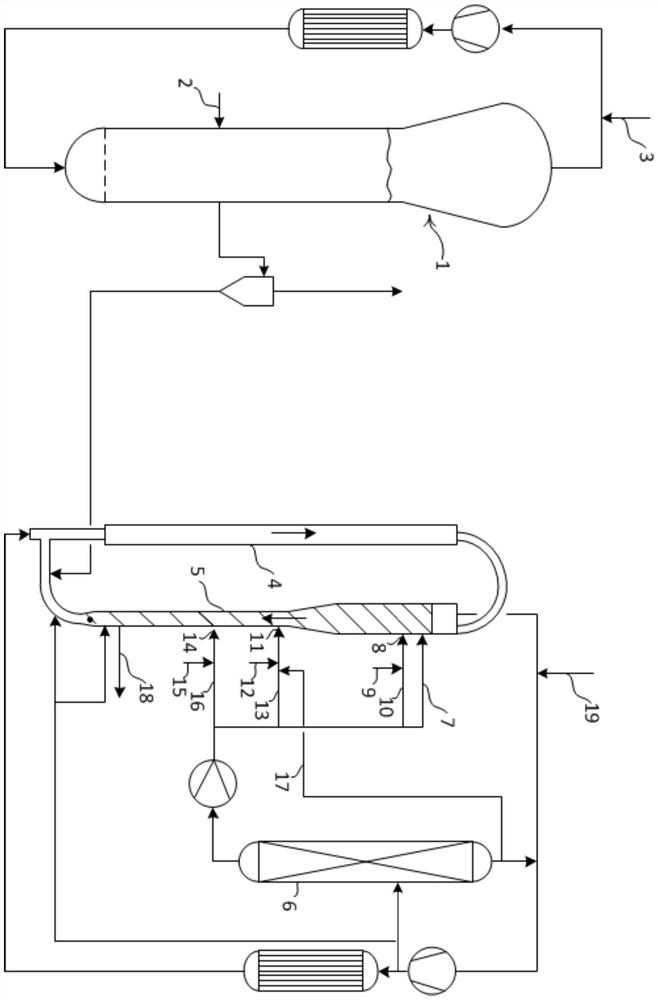

[0210] Polyethylene is produced in a cascade of fluidized bed reactors and multi-zone circulation reactors with two interconnected reaction zones, as shown in Figure 1.

[0211] For the polymerization, 9.5 g / h of the solid catalyst prepared as described above were fed using 1.5 kg / h of liquid propane into a first stirred precontacting vessel, into which triisobutylaluminum (TIBA) was also metered. The weight ratio of aluminum alkyl to Ziegler catalyst is 2:1. The first precontact vessel was maintained at 40°C with an average residence time of 25 minutes. The catalyst suspension of the first precontacting vessel was continuously transferred to a second stirred precontacting vessel, operated with an average residence time of 25 minutes and also maintained at 40°C. The catalyst suspension is then continuously transferred via line (2) into a fluidized bed reactor (FBR) (1 ).

[0212] In the fluidized bed reactor (1), ethylene is polymerized using hydrogen as molecular weight reg...

Embodiment 2

[0222] The conditions remained the same as Example 1 except that 47 kg / h of ethylene, 150 g / h of hydrogen and 11 kg / h of propane were fed to the fluidized bed reactor (1 ) via line 3 . The selected feed rate resulted in an ethylene concentration in the reactor of 6.6 vol.-%, and a hydrogen / ethylene molar ratio in the reactor of 2.7.

[0223] The polyethylene obtained in the fluidized bed reactor (1) has an MFR of 99 g / 10 min and a MFR of 0.968 g / cm 3 Density.

[0224] Feed the monomer in the downcomer in 3 positions. At feed point 1 (8), 25 kg / h of liquid condensate (10), 10 kg / h of ethylene (9) and 450 g / h of 1-hexene (9) were introduced. At feed point 2 (11), 15 kg / h of liquid condensate (13) and 5 kg / h of ethylene (12) are introduced. At feed point 3 (14), 15 kg / h of liquid condensate (16) and 5 kg / h of ethylene (15) are fed. 5 kg / h of propane, 34.8 kg / h of ethylene and 6.5 g / h of hydrogen are fed into the circulation system via line 19 .

[0225] The liquid condensate...

Embodiment 3

[0230] The conditions were kept the same as in Example 1, except that 10.5 g / h of solid catalyst and 0.21 g / h of tetrahydrofuran (THF) were fed into the first stirred precontact vessel using 1.5 kg / h of liquid propane for the polymerization, Triisobutylaluminum (TIBA) was also metered thereinto. The weight ratio of aluminum alkyl to Ziegler catalyst is 2:1.

[0231] 46 kg / h of ethylene, 185 g / h of hydrogen and 11 kg / h of propane are fed via line 3 to the fluidized bed reactor (1). The selected feed rate resulted in an ethylene concentration in the reactor of 7.3 vol.-%, and a hydrogen / ethylene molar ratio in the reactor of 3.4.

[0232] The polyethylene obtained in the fluidized bed reactor (1) has an MFR of 101 g / 10 min and a MFR of 0.968 g / cm 3 Density.

[0233] The multi-zone circulating reactor (MZCR) was operated at a pressure of 2.6 MPa and a temperature of 85°C measured at the gas outlet of the reactor, and in a unimodal setup with only the barrier flushed.

[0234]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com