Cooling device for aluminum alloy machining

A cooling device and technology of aluminum alloy, applied in the field of aluminum alloy processing, can solve the problems of reducing the cooling efficiency of aluminum alloy liquid and high temperature, and achieve the effects of improving cooling effect, improving cooling efficiency and releasing magnetic shielding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

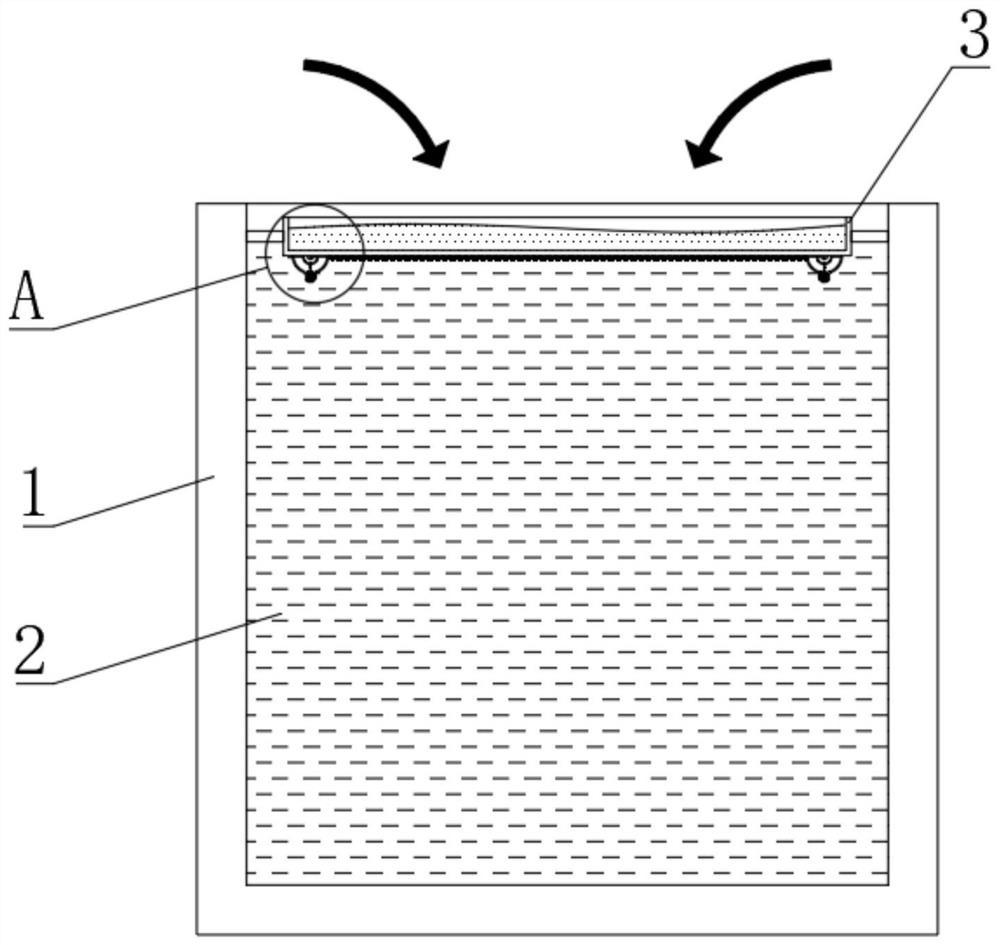

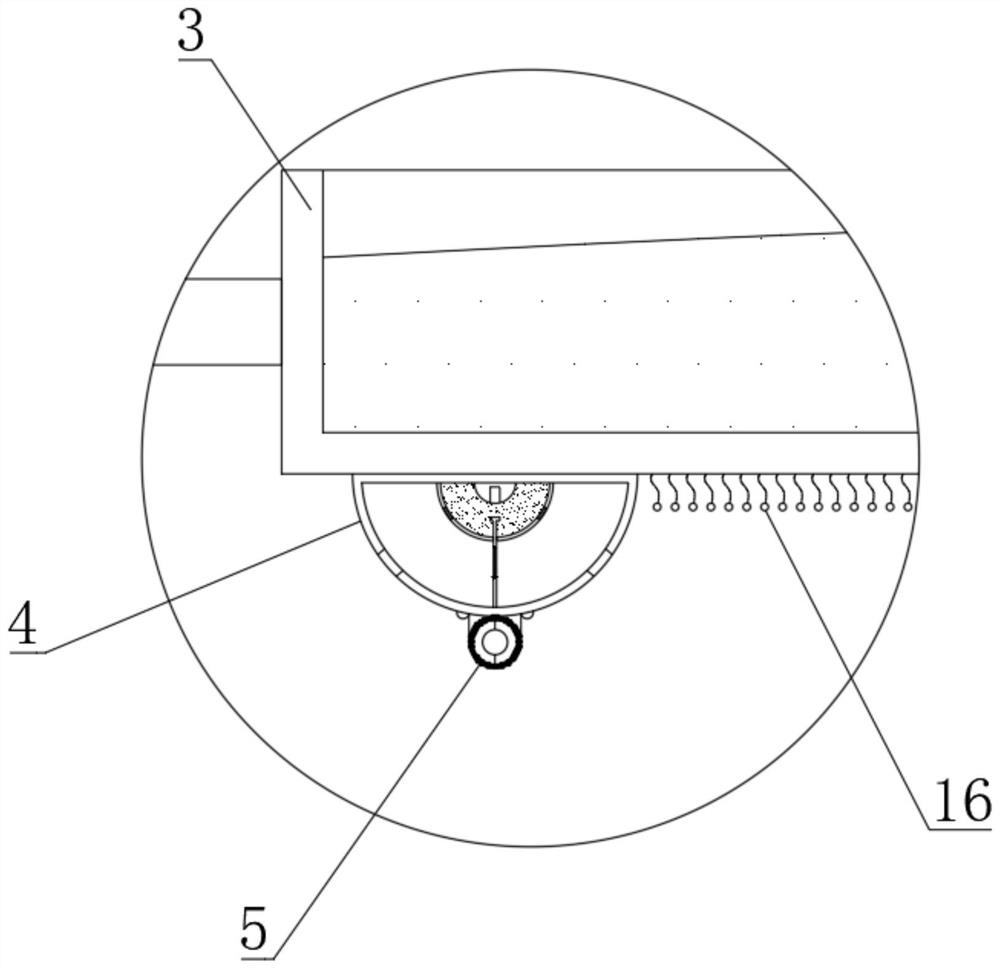

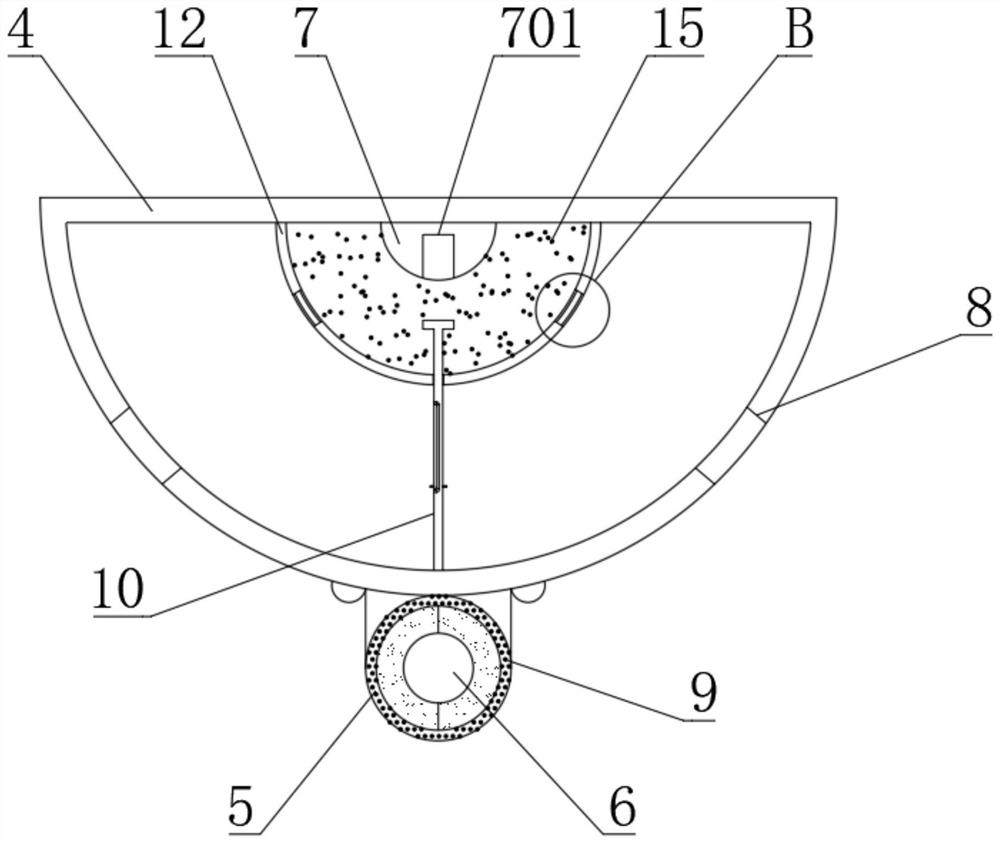

[0046] see Figure 1-3 , a cooling device for processing aluminum alloys, comprising a cooling box 1 filled with a cooling liquid 2, those skilled in the art can select a suitable cooling liquid 2, where the cooling liquid 2 is water, and the inner wall of the cooling box 1 is connected to There is a bearing mold 3, the bearing mold 3 is located on the liquid surface of the cooling liquid 2, a plurality of pairs of evenly distributed bubbling hemispheres 4 are glued to the bottom of the bearing mold 3, and two raised strips are arranged on the outer ends of the bubbling hemispheres 4. The strips are located on both sides of the phase-change heat dissipation hose 5, and the outer end of each bubbling hemisphere 4 is provided with a phase-change heat dissipation hose 5 connected to the bottom end of the carrying mold 3, and the inner wall of the phase-change heat dissipation hose 5 is connected with a built-in magnetic The ball 6 and the inner top of the bubbling hemisphere 4 ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com