Crystal cluster type inorganic binding agent and preparation method thereof

An inorganic binder and crystal cluster type technology, which is applied in glass manufacturing equipment, manufacturing tools, glass furnace equipment, etc., can solve the problems of complex process and high energy consumption, and achieve large number of crystal nuclei, easy nucleation and grain size. The effect of control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

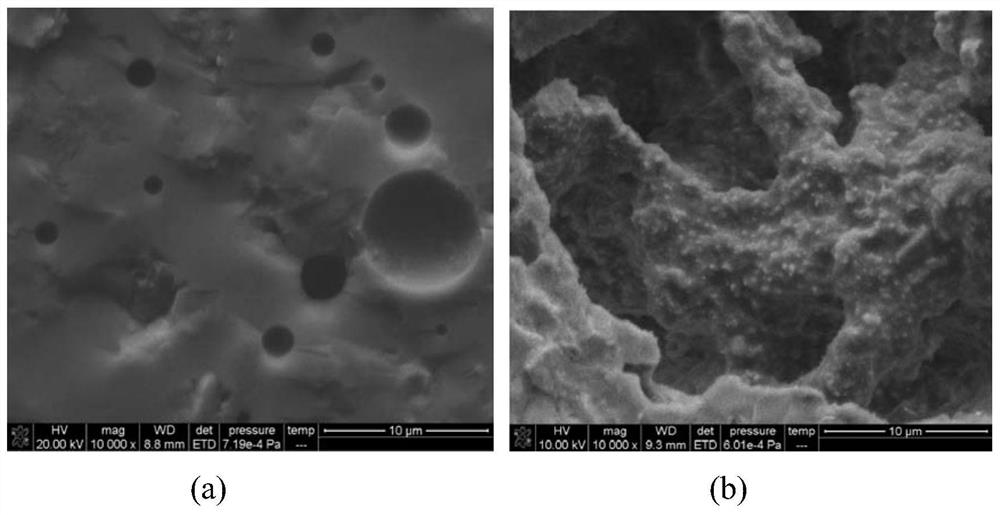

Image

Examples

Embodiment 1

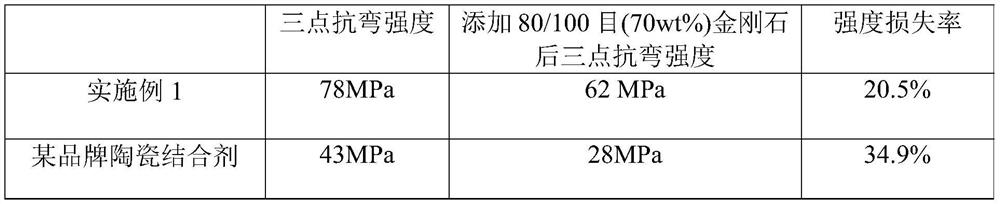

[0022] Embodiment 1: preparation is used for the high silicon type inorganic binder of diamond grinding tool

[0023] ① Formula:

[0024] SiO 2 60wt%, Al 2 o 3 5wt%, B 2 o 3 15wt%, K 2 O 1wt%, Li 2 O 1wt%, Na 2 O 8wt%, ZnO 1wt%, BaO 1wt%, MgO 1wt%, ZrO 2 4wt%, TiO 2 3 wt%.

[0025] ②Preparation method:

[0026] Grind the above raw materials through a 100-mesh screen respectively, then weigh them according to the chemical ratio, stir them evenly and pass through a 100-mesh screen three times, and finally put the raw materials after the sieve into an alumina crucible and put them in a high-temperature melting furnace Melting, the smelting process is as follows: first heat up to 1350°C at a heating rate of 10°C / min, and hold for 60 minutes; then drop to 1200°C at a rate of 15°C / min, quickly pour the material after holding for 30 minutes, quench water, and ball mill to obtain a certain particle size water-quenched binder (50 μm). The ball-milled material is sinte...

Embodiment 2

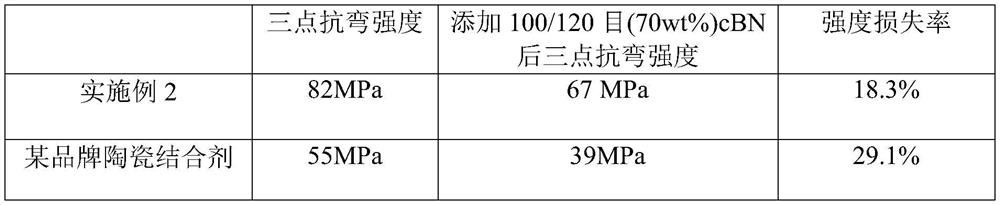

[0032] Embodiment 2: preparation is used for the high aluminum type inorganic binder of cubic boron nitride (cBN) grinding tool

[0033] ① Formula:

[0034] SiO 2 20wt%, Al 2 o 323wt%, B 2 o 3 15wt%, K 2 O 5wt%, Li 2 O 8wt%, Na 2 O 8wt%, ZnO 4wt%, BaO 5wt%, MgO 5wt%, ZrO 2 2wt%, TiO 2 3wt%, P 2 o 5 , 2wt%.

[0035] ②Preparation method:

[0036] Grind the above raw materials through a 100-mesh screen respectively, then weigh them according to the chemical ratio, stir them evenly and pass through a 100-mesh screen three times, and finally put the raw materials after the sieve into an alumina crucible and put them in a high-temperature melting furnace Melting, the melting process is as follows: firstly heat up to 1600°C at a heating rate of 3°C / min, and hold for 180 minutes; Water quenched binder (15 μm). The material after ball milling is sintered. The sintering process is as follows: firstly, the heating rate is 3°C / min to 80°C, and the temperature is kept fo...

Embodiment 3

[0042] Embodiment 3: preparation is used for precision grinding diamond tool vitrified bond

[0043] ① Formula:

[0044] SiO 2 45wt%, Al 2 o 3 15wt%, B 2 o 3 10wt%, K 2 O 1wt%, Li 2 O 4wt%, Na 2 O 5wt%, ZnO 4wt%, BaO 5wt%, MgO 5wt%, ZrO 2 2wt%, TiO 2 4wt%.

[0045] ②Preparation method:

[0046] Grind the above raw materials through a 100-mesh screen respectively, then weigh them according to the chemical ratio, stir them evenly and pass through a 100-mesh screen three times, and finally put the raw materials after the sieve into an alumina crucible and put them in a high-temperature melting furnace Melting, the smelting process is as follows: firstly heat up to 1400°C at a heating rate of 5°C / min, and hold for 120 minutes; Water quenched binder (0.01 μm). The material after ball milling is sintered. The sintering process is as follows: firstly, the heating rate is 2°C / min to 100°C, and the heat preservation is 50 minutes; then the heating rate is 5°C / min to 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com