High-speed cap screwing device and cap screwing machine

A high-speed, capping technology, applied in the direction of screw caps, etc., can solve the problems of damaging caps or bottles, affecting the speed of capping, and not working properly, and achieves the effects of increasing speed, saving pipelines, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

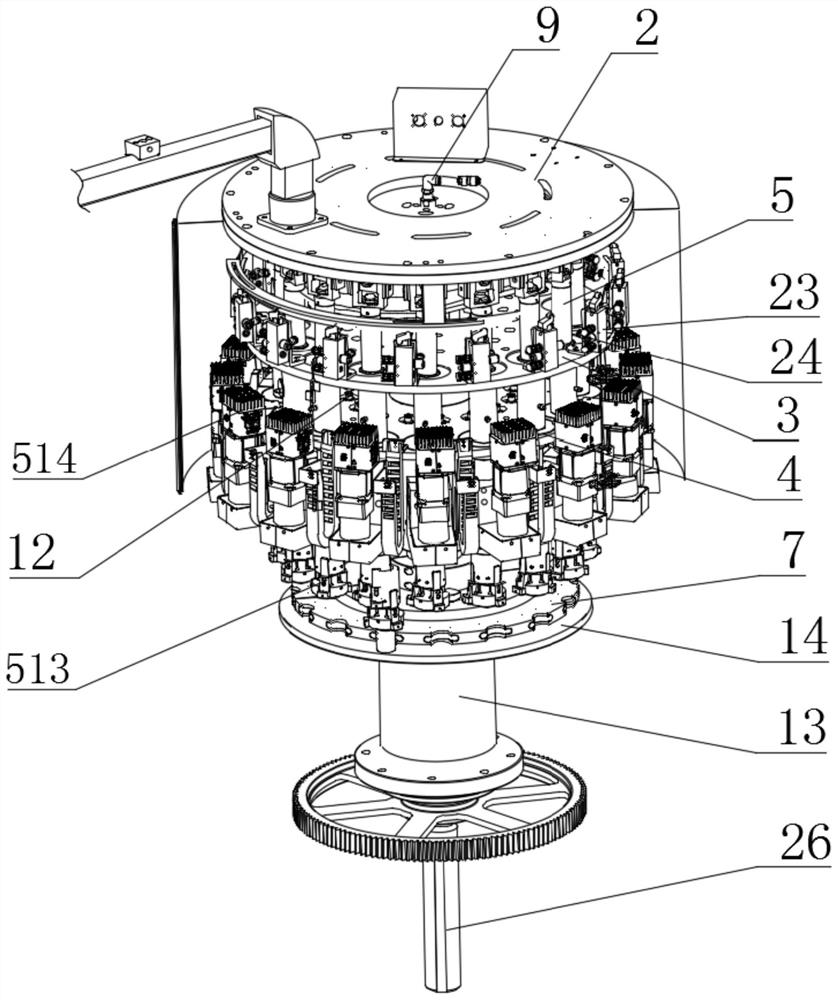

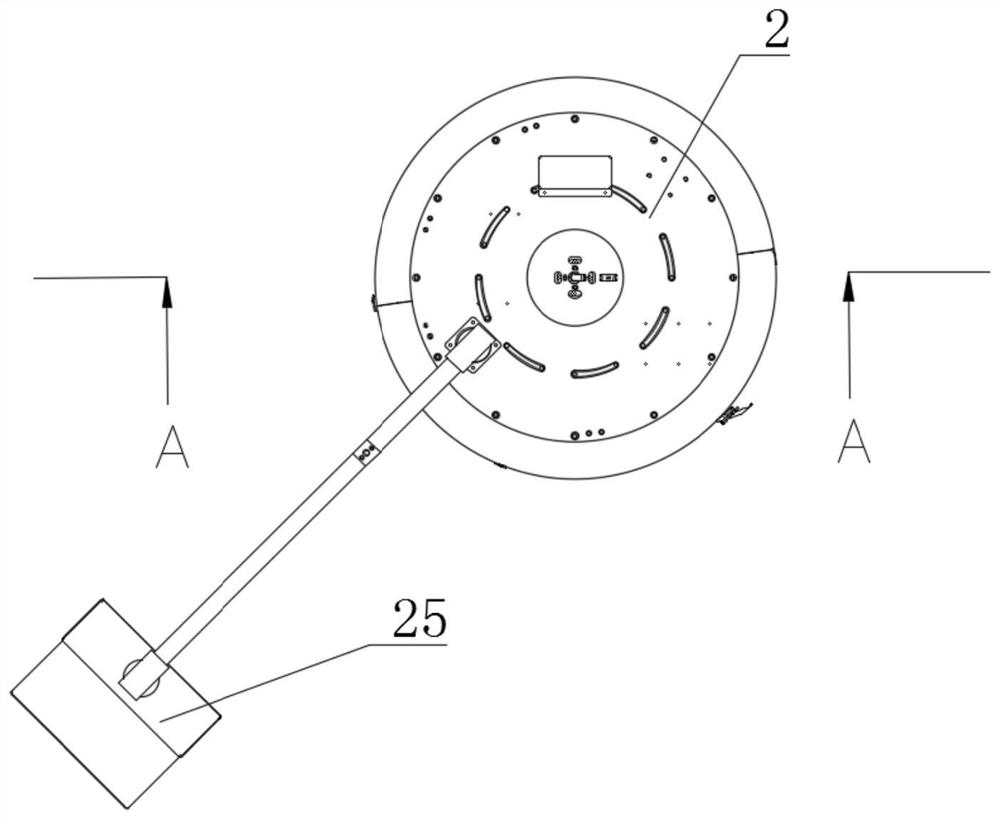

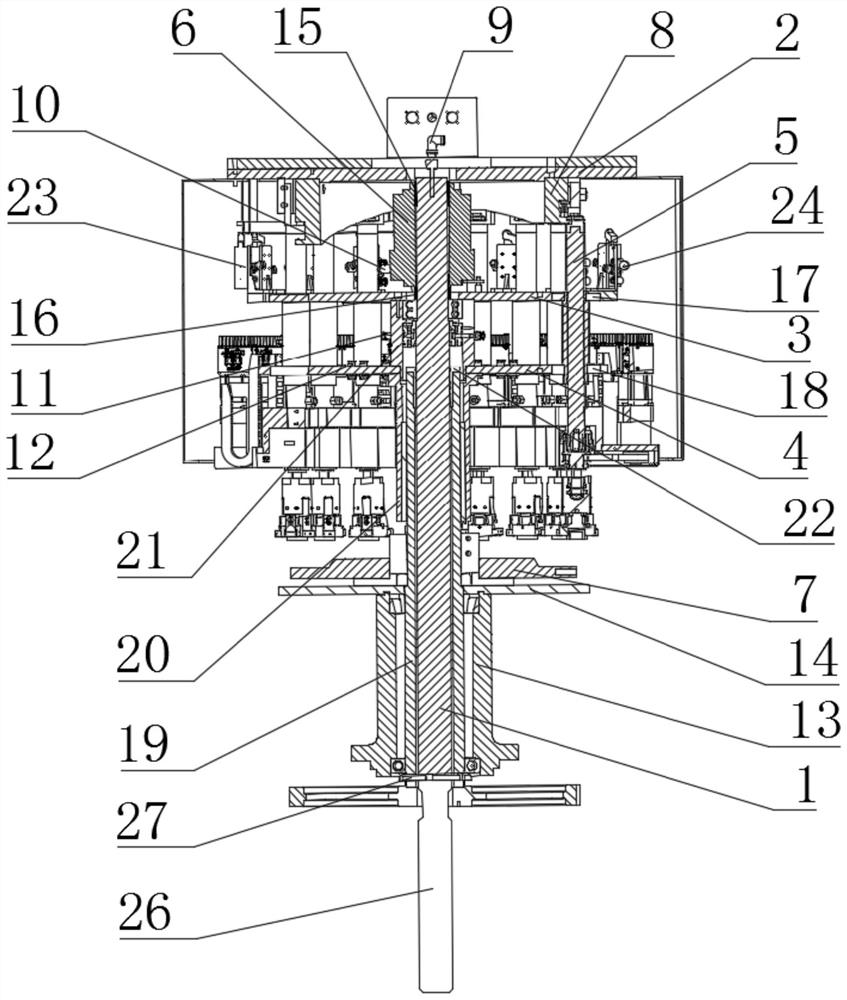

[0027] A high-speed capping device 1-1, such as Figure 1 to Figure 3As shown, it includes a main body panel 2 , a rotating shaft 1 , a rotating support frame, a main astrolabe 7 , a slip ring 6 and a screw cap assembly 5 , and a control panel 25 is also connected to the main body panel 2 . The main body panel 2 is fixed on the frame, the main body panel 2 is provided with a cover cam 8, the upper end of the rotating shaft 1 is rotatably connected with the main body panel 2, and the rotating shaft 1 is connected to the rotating shaft The support frames are fixedly connected to drive the rotating support frame to rotate. There are various forms and structures of the rotating support frame. As one of the implementations, the rotating support frame of this embodiment includes an upper rotating disk 3, a lower rotating disk 4 and a support assembly arranged at intervals along the rotating shaft 1. .

[0028] There are several screw cap assemblies 5, and several of the screw cap ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com