Tetrahydrofuranoindole compound as well as preparation method and application thereof

A technology of tetrahydrofuran and compounds, applied in the field of medicinal chemistry, to achieve good inhibitory activity, high yield and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

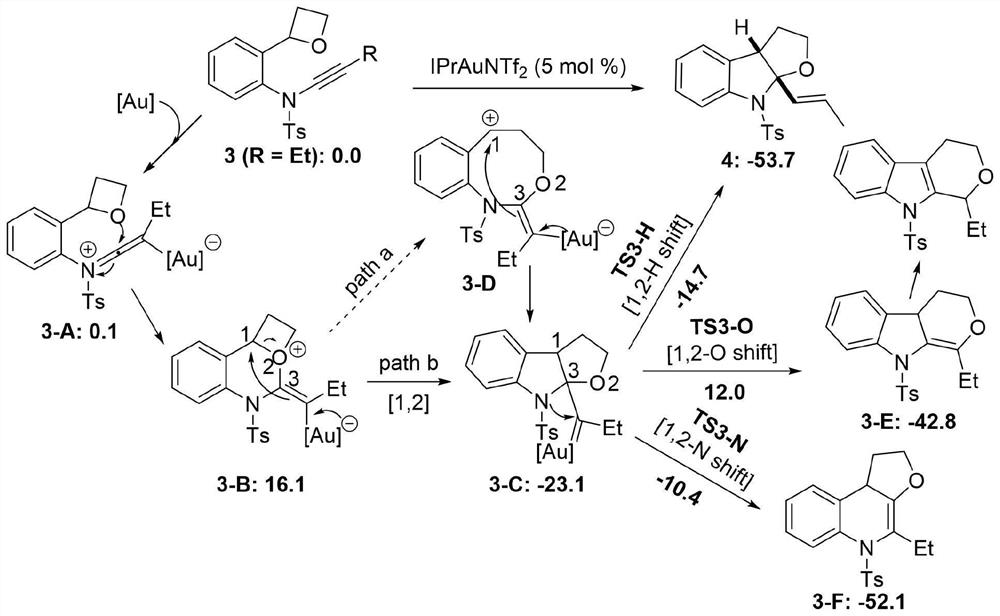

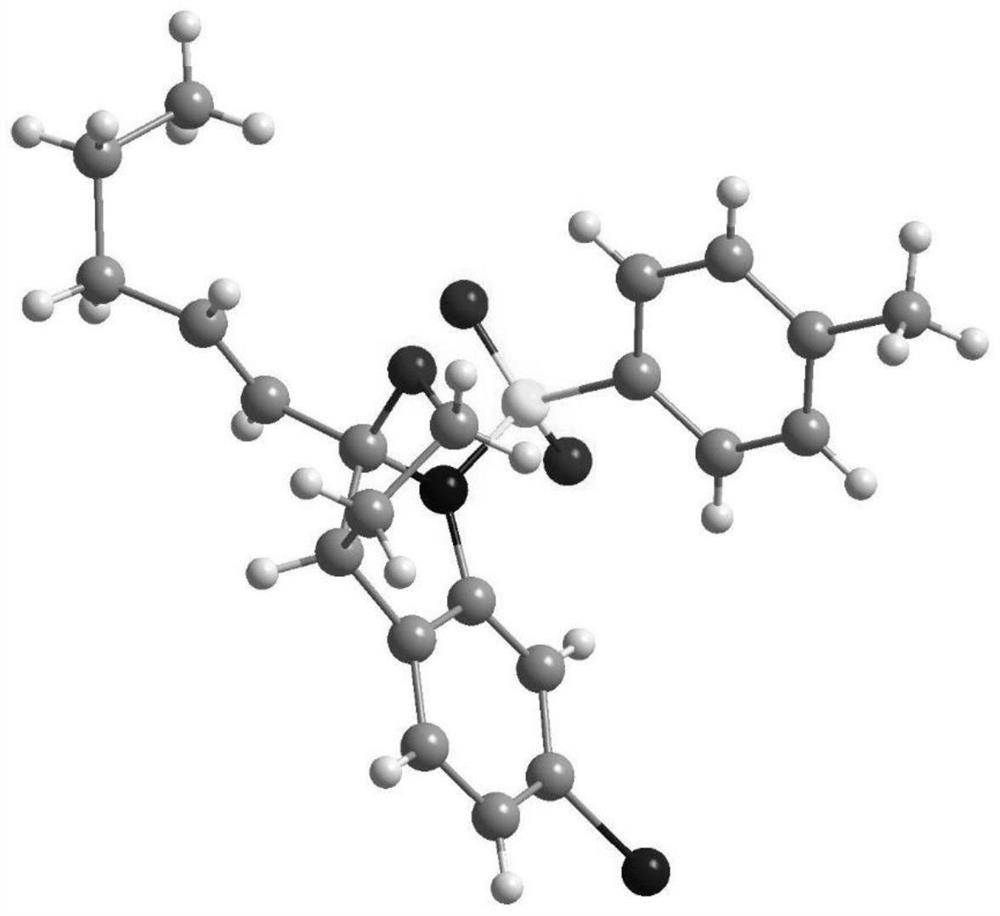

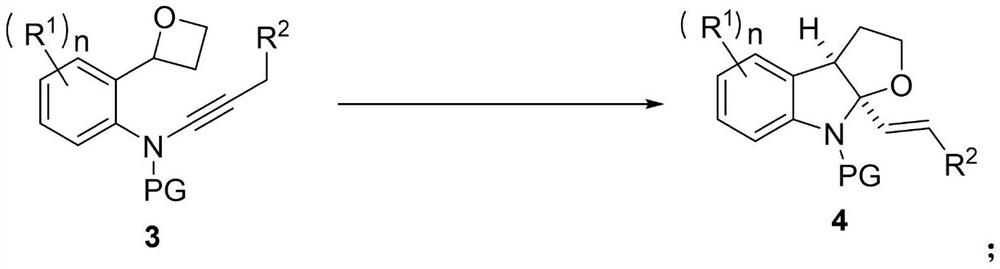

Method used

Image

Examples

Embodiment 1

[0028] The synthesis of embodiment 1 compound 4a

[0029]

[0030] wxya 2 (0.01mmol, 8.7mg) was added to the dichloromethane solution (4mL, 0.05M) of the propargyl amine compound (0.2mmol) shown in formula 3a, and the reaction was protected with nitrogen, and the reaction mixture was stirred at room temperature. Reaction 1 Hours, the raw material of formula 3a was completely consumed through TLC monitoring, then the reaction mixture was concentrated to obtain a residue, and the residue was separated by silica gel column chromatography with n-hexane / ethyl acetate as the eluting solvent to obtain tetrahydrofuran shown in formula 4a and Indole compounds. Yield 99% yield (70.4mg) colorless oily liquid. 1 H NMR (400MHz, CDCl 3 )δ7.92(d, J=8.4Hz, 2H), 7.54(d, J=8.0Hz, 1H), 7.24–7.15(m, 3H), 7.09(d, J=7.2Hz, 1H), 7.00– 6.92(m,1H),6.06–5.82(m,2H),3.92(t,J=7.6Hz,1H),3.67(d,J=8.8Hz,1H),3.06–2.96(m,1H),2.35 (s,3H),2.31–2.22(m,1H),1.90–1.82(m,1H),1.77(dd,J=6.4,1.2Hz,3H); 13 C NMR...

Embodiment 2

[0031] The synthesis of embodiment 2 compound 4b

[0032]

[0033] wxya 2 24 Hours, the raw material of formula 3b was completely consumed through TLC monitoring, then the reaction mixture was concentrated to obtain a residue, and the residue was separated by silica gel column chromatography with n-hexane / ethyl acetate as the eluting solvent to obtain tetrahydrofuran shown in formula 4b and Indole compounds. Yield 64% (55.6 mg); white solid (mp 122–123°C). 1 H NMR (400MHz, CDCl 3 )δ7.88(d, J=8.4Hz, 2H), 7.43(d, J=8.8Hz, 1H), 7.32–7.28(m, 1H), 7.25–7.17(m, 3H), 6.02–5.86(m ,2H),3.92(t,J=8.0Hz,1H),3.64(d,J=8.8Hz,1H),3.02–2.93(m,1H),2.37(s,3H),2.33–2.21(m, 1H), 1.88–1.81(m, 1H), 1.77(d, J=5.2Hz, 3H); 13 C NMR (100MHz, CDCl 3 )δ143.7, 141.2, 137.1, 132.1, 132.0, 131.2, 129.1, 127.9, 127.7, 126.6, 115.4, 114.2, 107.0, 67.9, 53.4, 33.5, 21.5, 17.5; HRESIMS Calcd for [C 20 h 20 BrNNaO 3 S] + (M+Na + ) 456.0239, found 456.0238.

Embodiment 3

[0034] The synthesis of embodiment 3 compound 4c

[0035]

[0036] wxya 2 (0.01mmol, 8.7mg) was added to the dichloromethane solution (4mL, 0.05M) of the propargyl amine compound (0.2mmol) shown in formula 3c, and the reaction was protected with nitrogen, and the reaction mixture was stirred at room temperature. Reaction 1 Hours, the raw material of formula 3c monitored by TLC has been completely consumed, then the reaction mixture is concentrated to obtain a residue, and the residue is separated by silica gel column chromatography with n-hexane / ethyl acetate as the eluting solvent to obtain tetrahydrofuran shown in formula 4c and Indole compounds. Yield 99% (73.2 mg); white solid (mp 155–156°C). 1 H NMR (400MHz, CDCl 3 )δ7.90(d, J=8.4Hz, 2H), 7.43(d, J=8.0Hz, 1H), 7.20(d, J=8.4Hz, 2H), 7.03–6.95(m, 1H), 6.90( s,1H),6.03–5.84(m,2H),3.89(t,J=7.6Hz,1H),3.62(d,J=8.4Hz,1H),2.03–2.93(m,1H),2.34(s ,3H),2.31–2.19(m,4H),1.88–1.80(m,1H),1.76(dd,J=6.0,1.2Hz,3H); 13 C NMR (100MH...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com