A kind of water reducing agent and preparation method thereof

A technology of water reducing agent and mixing water, which is applied in the field of water reducing agent and its preparation, which can solve the problems of poor adaptability, formaldehyde generation, and low sensitivity, and achieve excellent slump retention performance, strong mud resistance, and low sensitivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

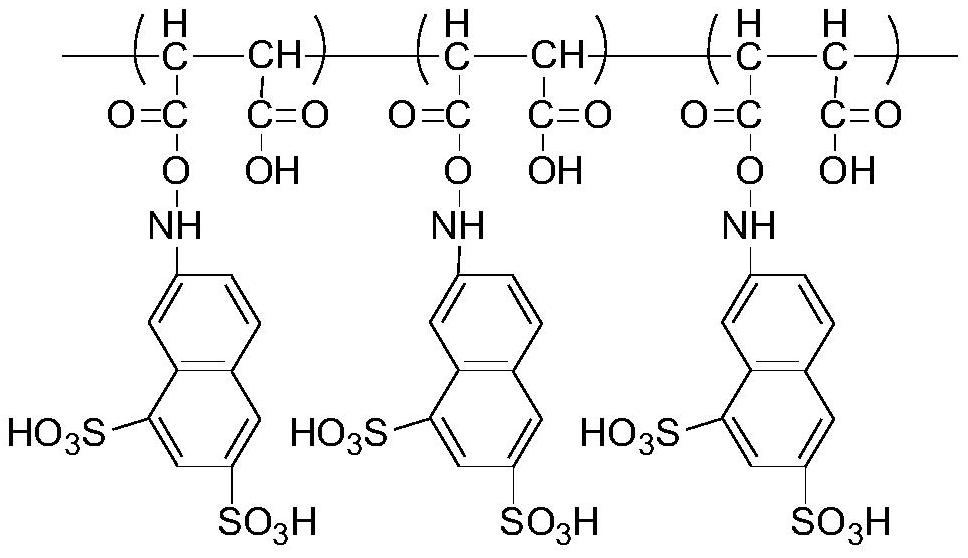

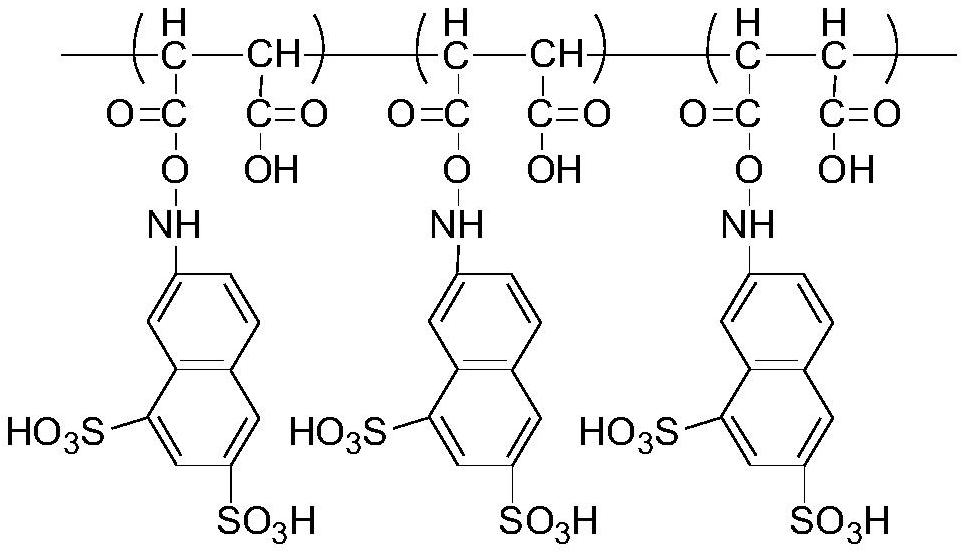

Method used

Image

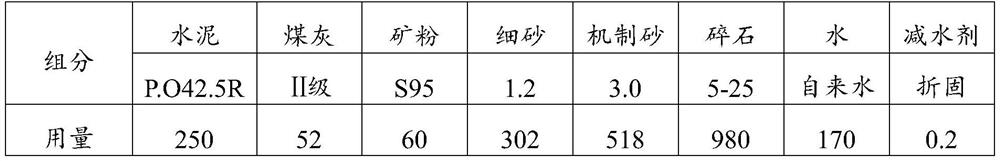

Examples

preparation example Construction

[0046] The present invention also provides a method for preparing a water reducing agent. In parts by weight, the preparation of the water reducing agent includes the following steps:

[0047] Add 100 to 200 parts of aminonaphthalene disulfonic acid maleamide esterification monomer and 200 parts of mixing water into the first reaction vessel, stir and dissolve, and raise and maintain the temperature in the first reaction vessel to 60°C to 90°C °C; and add the first mixed solution and the second mixed solution to the first reaction container, and continue to react for 0.5h to 2h to obtain the water reducing agent;

[0048] Wherein, the first mixed solution is 1 to 10 parts of initiator and 50 parts of mixing water;

[0049] The second mixed solution is 0.5-10 parts of chain transfer agent, 0.2-2 parts of reducing agent and 50 parts of mixing water.

[0050] The preparation method of the water reducer provided by the present invention, compared with the prior art, in the presen...

Embodiment 1

[0072] (1) Preparation of aminonaphthalene disulfonic acid maleamide esterification monomer:

[0073] In parts by weight, add 300 parts of 7-amino-1,3-naphthalene disulfonic acid, 100 parts of maleic anhydride, 0.5 parts of p-toluenesulfonic acid and 500 parts of water into the second reaction vessel, heat to 95°C, React at this temperature for 8 hours. After the reaction, cool down to obtain the maleamide esterified monomer of aminonaphthalene disulfonic acid;

[0074] (2) Preparation of water reducing agent:

[0075] In parts by weight, add 200 parts of aminonaphthalene disulfonic acid maleamide esterification monomer and 200 parts of mixing water into the first reaction container, stir and dissolve, and raise and maintain the temperature in the first reaction container At 70°C; then add the first mixed solution and the second mixed solution dropwise to the first reaction container at the same time, and after 2.5 hours of dropwise addition, continue to react for 1 hour, aft...

Embodiment 2

[0079] (1) Preparation of aminonaphthalene disulfonic acid maleamide esterification monomer:

[0080] In parts by weight, add 300 parts of 6-amino-1,3-naphthalene disulfonic acid, 110 parts of maleic anhydride, 0.5 parts of p-toluenesulfonic acid and 500 parts of water into the second reaction vessel, heat to 95°C, React at this temperature for 8 hours. After the reaction, cool down to obtain the maleamide esterified monomer of aminonaphthalene disulfonic acid;

[0081] (2) Preparation of water reducing agent:

[0082] In parts by weight, add 200 parts of aminonaphthalene disulfonic acid maleamide esterification monomer and 200 parts of mixing water into the first reaction vessel, heat and stir to dissolve, and keep the temperature in the first reaction vessel at 70 ℃; then add the first mixed solution and the second mixed solution dropwise to the first reaction container at the same time, after the dropwise addition, continue to react for 1h, after the reaction is completed,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com