Water-based low-surface-treatment coating as well as preparation method and application thereof

A low surface treatment and coating technology, applied in anti-corrosion coatings, coatings, etc., to achieve the effect of simple method, easy operation, and avoidance of damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

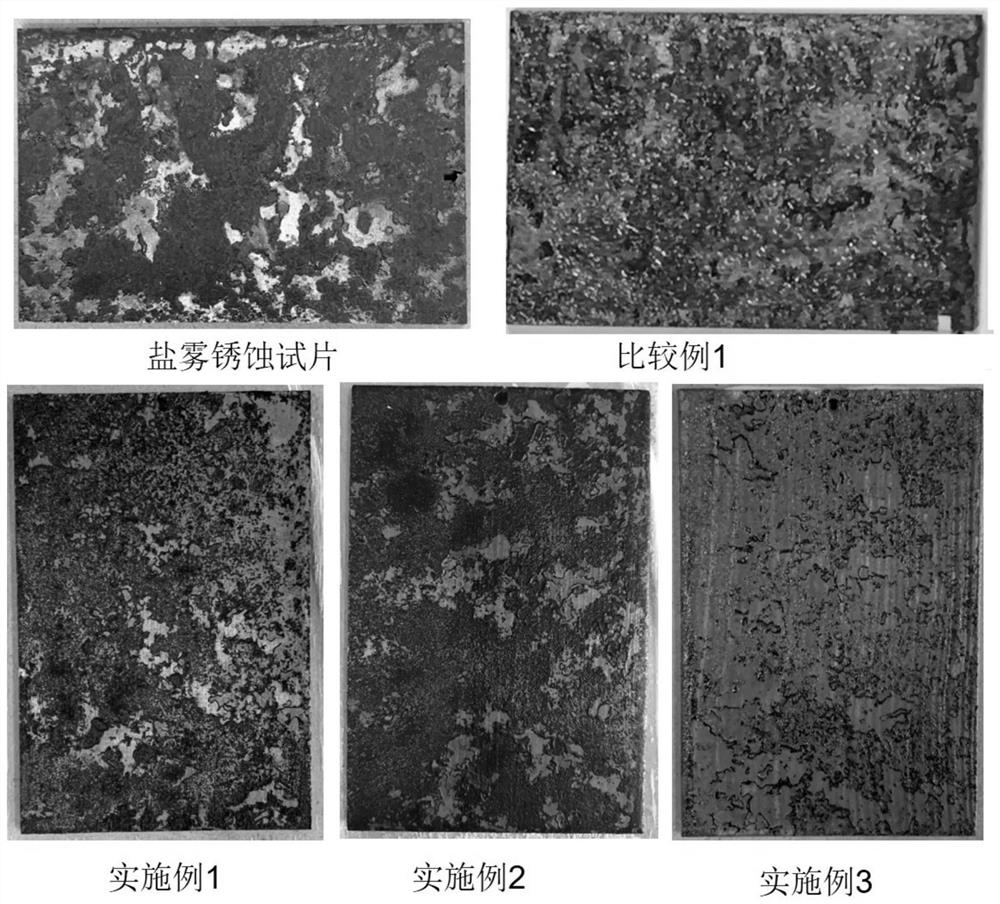

Embodiment 1

[0050] Prepare raw materials according to the following mass ratios: 200 parts of acidic group modified acrylic resin emulsion (pH2-4), 20 parts of rust conversion functional components (phosphoric acid), 10 parts of functional corrosion inhibitor (zinc phosphate), 8 parts of penetrating agent (glycerin) 1 part, 1 part of defoamer (organic silicon modified defoamer), 60 parts of deionized water.

[0051] (1) Dissolve 20 parts of phosphoric acid, 10 parts of zinc phosphate, and 8 parts of glycerin in 60 parts of deionized water, and stir at 1000 rpm for 0.5 h to obtain component A;

[0052] (2) Add 1 part of silicone-modified defoamer to 100 parts of acid group-modified acrylic resin emulsion and stir at 100 rpm for 0.5 h to obtain component B;

[0053] (3) Slowly add component A in step (1) to component B in step (2) to prepare a mixed solution, and stir at 100 rpm for 0.5 h for later use.

Embodiment 2

[0055] The raw materials are prepared according to the following mass ratios: 200 parts of acidic group modified acrylic resin emulsion (pH2-4), 30 parts of rust conversion functional components (a mixture of phosphoric acid and phytic acid at a ratio of 9:1), functional corrosion inhibitor (zinc phosphate and aluminum tripolyphosphate at a ratio of 1:1) 12 parts, penetrating agent (a mixture of glycerin and EDTA at a ratio of 1:1) 10 parts, defoamer (organosilicon modified defoamer) 1 part, deionized 60 parts of water.

[0056] (1) Dissolve 30 parts of a mixture of phosphoric acid and phytic acid, 10 parts of a mixture of zinc phosphate and aluminum tripolyphosphate, 8 parts of a mixture of glycerin and EDTA in 60 parts of deionized water, and stir at 1000 rpm for 1 hour to obtain component A;

[0057] (2) Add 1 part of silicone-modified defoamer to 100 parts of acid group-modified acrylic resin emulsion and stir at 100 rpm for 0.5 h to obtain component B;

[0058] (3) Slowl...

Embodiment 3

[0060] Prepare raw materials according to the following mass ratio: 200 parts of acidic group modified acrylic resin emulsion (pH2-4), rust conversion functional components (a mixture of phosphoric acid, phytic acid, tannic acid and acetic acid at a ratio of 7:1:1:1) 40 parts, functional corrosion inhibitor (a mixture of zinc phosphate, aluminum tripolyphosphate and hexamethylenetetramine at a ratio of 1:1:1) 12 parts, penetrating agent (glycerin, EDTA and flattened at a ratio of 2:1:1) mixture) 10 parts, defoamer (organic silicon modified defoamer) 1.5 parts, deionized water 30-80 parts.

[0061] (1) Dissolve 40 parts of phosphoric acid, phytic acid, tannic acid, acetic acid mixture, 12 parts of zinc phosphate, aluminum tripolyphosphate, hexamethylenetetramine mixture, 10 parts of glycerin, EDTA and flat plus mixture in 60 part deionized water, stirred at 1000rpm for 1h to obtain component A;

[0062] (2) Add 1.5 parts of silicone-modified defoamer to 200 parts of acid group...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com