Process for preparing ultra-pure coal by using acid-alkali method

A technology of acid-alkali method and process, which is applied in the field of preparing ultra-pure coal by acid-alkali method, and can solve the problems of inability to obtain ultra-pure coal and high process conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

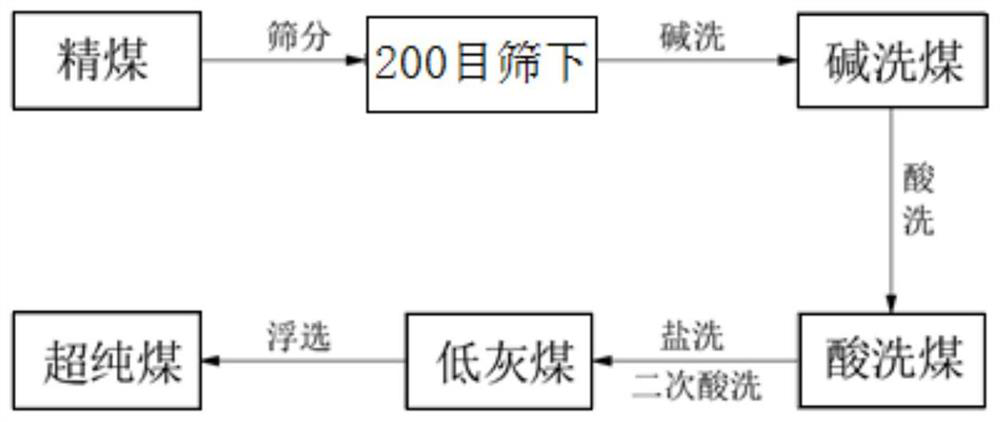

[0025] A process for preparing ultra-pure coal by an acid-base method, comprising the following steps:

[0026] (1) Prepare experimental instruments and medicines

[0027] Instruments: electric magnetic stirrer, circulating water vacuum pump, 101 type electric blast drying oven, muffle furnace, analytical balance, small electromagnetic pulverizer;

[0028] Agent: aviation kerosene (dispersant), 20wt% NaOH solution, 49wt% sulfuric acid solution, 25wt% dilute hydrochloric acid solution, 12wt% sodium carbonate solution, CaO, 15wt% ZnCl solution;

[0029] (2) Prepare coal samples

[0030] Prepare the single coal JM2 and FM2 in the coking plant, the ash content is 9.08%, 9.83%, respectively. The experimental coal samples were pulverized by a small electromagnetic pulverizer and passed through a 200-mesh sieve.

[0031] (3) Preparation of ultra-pure coal

[0032] as attached figure 1 As shown, the ultrapure coal was prepared according to the following procedure.

[0033] A. Al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com