Ti-V-Mo-Zr-Cr-Al series high-strength metastable beta titanium alloy and manufacturing method thereof

A ti-v-mo-zr-cr-al, β titanium alloy technology, applied in the direction of temperature control, etc., can solve the problem that the strength of titanium alloy cannot meet the use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The preparation method of the above-mentioned Ti-V-Mo-Zr-Cr-Al series high-strength metastable β-titanium alloy comprises the following steps:

[0034] Step 1. The raw materials are uniformly mixed according to weight percentage and loaded into a furnace in bulk, followed by induction suspension melting in a cold crucible, and cooling to obtain an ingot.

[0035] During the smelting process, argon gas is introduced, the induction current is 400-600A, and the current frequency is 20-25KHz. After the alloy is completely melted, it is kept for 3-5 minutes, and the ingot is obtained by cooling. The number of smelting times is not less than 5.

[0036] The raw materials used in the alloy smelting include: high-purity titanium, high-purity vanadium, high-purity molybdenum, high-purity aluminum, high-purity zirconium and high-purity chromium.

[0037] Step 2. Homogenize the obtained ingot at a high temperature of 1000° C. for 1 hour, and then water-cool to room temperature.

...

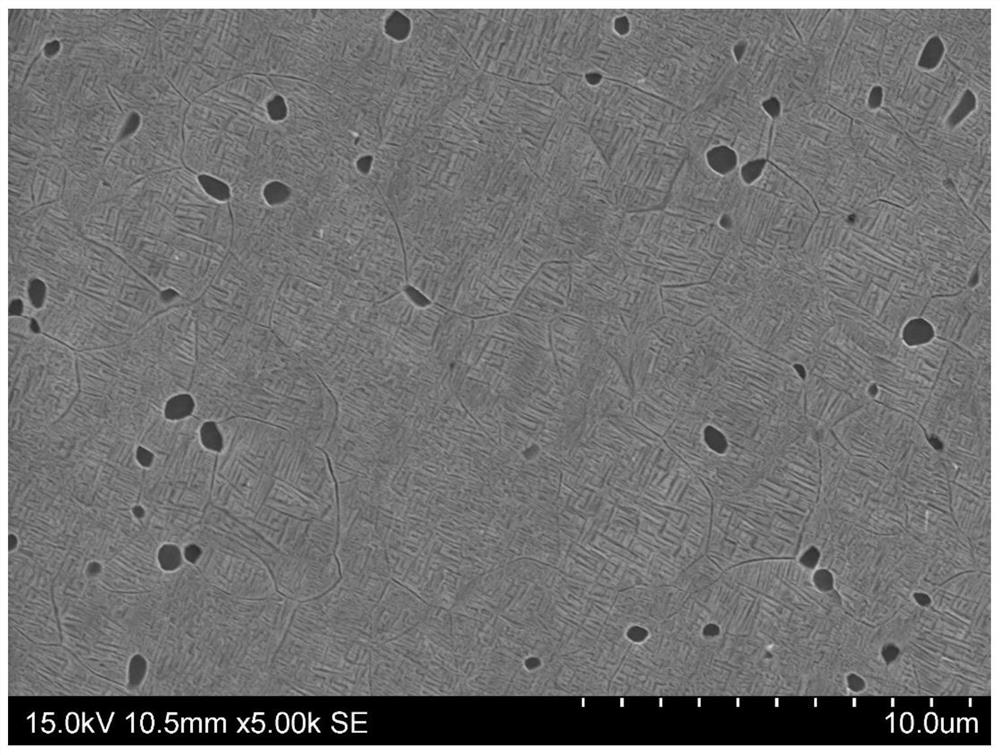

Embodiment 1

[0042] In this embodiment, Ti-V-Mo-Zr-Cr-Al is a new type of high-strength metastable β-titanium alloy, which consists of the following components by weight percentage: V 4%, Mo 8.5%, Zr 1%, Cr 2.5%, Al 5.5 %, the balance is Ti and unavoidable impurities.

[0043]The preparation method of the Ti-V-Mo-Zr-Cr-Al series high-strength metastable β-titanium alloy of this embodiment comprises the following steps:

[0044] (1) The raw materials used in the alloy smelting include: high-purity titanium, high-purity vanadium, high-purity molybdenum, high-purity aluminum, high-purity zirconium and high-purity chromium. The raw materials are mixed uniformly according to the proportion and loaded into the furnace in bulk, and then cooled Crucible induction suspension smelting, argon gas is introduced during the smelting process, the induction current is 400A, and the current frequency is 20KHz. After the alloy is completely melted, it is kept for 3 minutes, cooled to obtain an ingot, and sm...

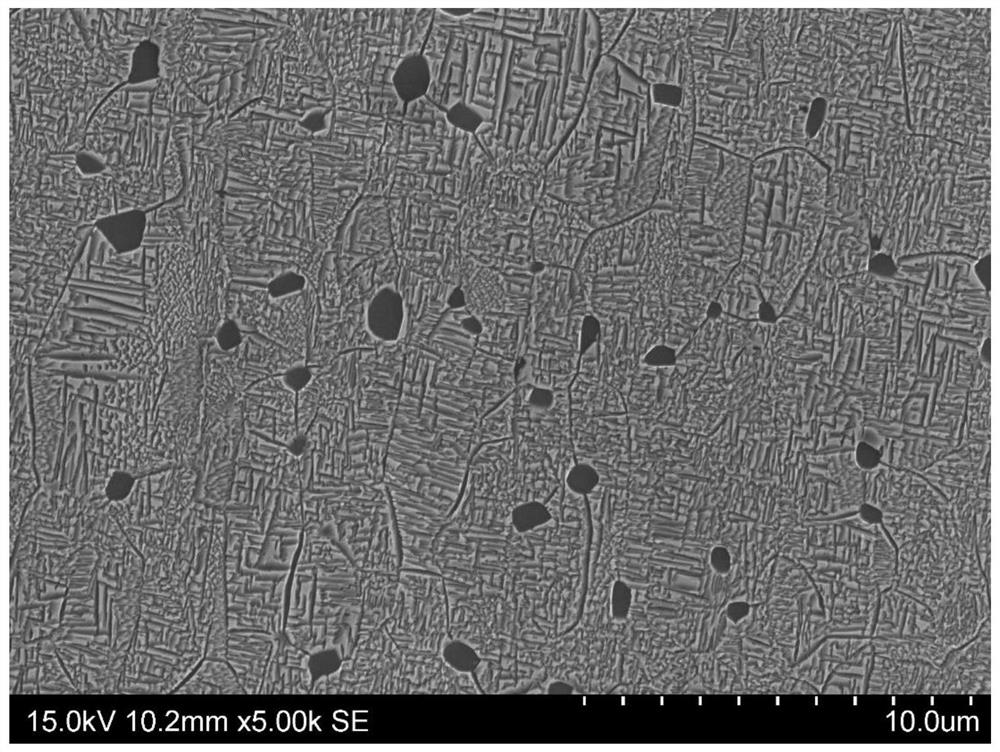

Embodiment 2

[0051] The Ti-V-Mo-Zr-Cr-Al high-strength metastable β-titanium alloy in this embodiment consists of the following components by weight percentage: V 5%, Mo 6%, Zr 1%, Cr 4%, Al 5% , the balance being Ti and unavoidable impurities.

[0052] The preparation method of the Ti-V-Mo-Zr-Cr-Al series high-strength metastable β-titanium alloy comprises the following steps:

[0053] (1) The raw materials used in the alloy smelting include: high-purity titanium, high-purity vanadium, high-purity molybdenum, high-purity aluminum, high-purity zirconium and high-purity chromium. The raw materials are mixed uniformly according to the proportion and loaded into the furnace in bulk, and then cooled Crucible induction suspension smelting, argon gas is introduced during the smelting process, the induction current is 500A, and the current frequency is 22KHz. After the alloy is completely melted, it is kept for 4 minutes, cooled to obtain an ingot, and smelted 8 times.

[0054] (2) Homogenize th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com