High-strength TWIP titanium alloy with gradient structure and hot rolling method thereof

A gradient structure, titanium alloy technology, applied in metal rolling and other directions, can solve the problem of low yield strength, achieve high yield strength, good strength and plasticity, and high elongation at break

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] A kind of hot-rolling method of the high-strength TWIP titanium alloy with gradient structure, comprises the following steps:

[0047] Step 1, the 8mm thick Ti-Al-Mo-Cr-Zr metastable β titanium alloy plate is kept at 1000°C for 60min in a muffle furnace, and then quenched to room temperature;

[0048] The composition of Ti-Al-Mo-Cr-Zr metastable β titanium alloy is 1.5-2.5% Al, 7-8% Mo, 3-4% Cr, 6-7% Zr, and the balance is Ti and Some other unavoidable impurities.

[0049] Step 2, keeping the 8mm thick Ti-Al-Mo-Cr-Zr metastable β titanium alloy plate in a muffle furnace at 765°C for 10min;

[0050] Step 3. Take it out and roll it. The reduction in a single pass is 4%. After every two passes of rolling, the sample is returned to the furnace and kept at 765° C. for 1 min. The total rolling reduction is 70%.

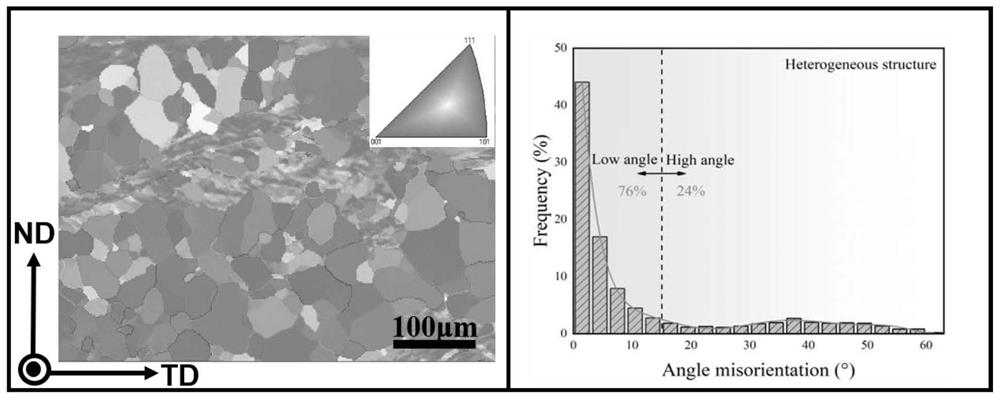

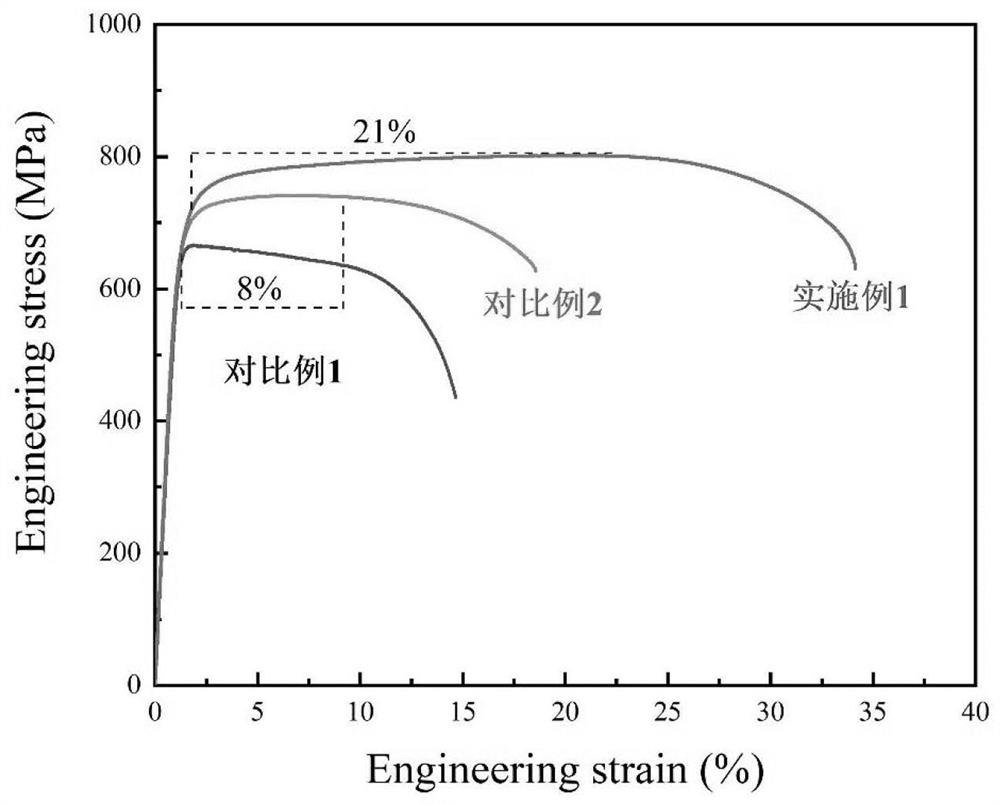

[0051] Step 4. Immediately put the rolled sample into a muffle furnace, keep it warm at 780° C. for 5 minutes, and then quench it to room temperature to obtain a h...

Embodiment 2

[0054] A kind of hot-rolling method of the high-strength TWIP titanium alloy with gradient structure, comprises the following steps:

[0055] Step 1, the 8mm thick Ti-Al-Mo-Cr-Zr metastable β titanium alloy plate is kept at 1100°C for 90min in a muffle furnace, and then quenched to room temperature;

[0056] The composition of Ti-Al-Mo-Cr-Zr metastable β titanium alloy is 1.5-2.5% Al, 7-8% Mo, 3-4% Cr, 6-7% Zr, and the balance is Ti and Some other unavoidable impurities.

[0057] Step 2, keeping the 8mm thick Ti-Al-Mo-Cr-Zr metastable β titanium alloy plate in a muffle furnace at 790°C for 15min;

[0058] Step 3. Take it out and roll it. The reduction in a single pass is 7%. After every two passes, the sample is returned to the furnace and kept at 765° C. for 2 minutes. The total rolling reduction is 80%.

[0059] Step 4. Immediately put the rolled sample into a muffle furnace, keep it at 790° C. for 7 minutes, and then quench it to room temperature to obtain a high-strength...

Embodiment 3

[0062] A kind of hot-rolling method of the high-strength TWIP titanium alloy with gradient structure, comprises the following steps:

[0063] Step 1, the 8mm thick Ti-Al-Mo-Cr-Zr metastable β titanium alloy plate is kept at 1200°C for 120min in a muffle furnace, and then quenched to room temperature;

[0064] The composition of Ti-Al-Mo-Cr-Zr metastable β titanium alloy is 1.5-2.5% Al, 7-8% Mo, 3-4% Cr, 6-7% Zr, and the balance is Ti and Some other unavoidable impurities.

[0065] Step 2, keeping the 8mm thick Ti-Al-Mo-Cr-Zr metastable β titanium alloy plate in a muffle furnace at 815°C for 20min;

[0066] Step 3. Take it out and roll it. The reduction in a single pass is 10%. After every two passes of rolling, the sample is returned to the furnace and kept at 765° C. for 5 minutes. The total rolling reduction is 90%.

[0067] Step 4. Immediately put the rolled sample into a muffle furnace, keep it at 800° C. for 9 minutes, and then quench it to room temperature to obtain a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com