Drilling machine power head assembly, drilling machine power drill bit, and spiral drilling and production machine

A drilling rig power head, drilling machine technology, applied in the field of drilling rig power drill bit, drilling rig power head assembly, auger drilling machine, can solve the problems of heavy weight, low work efficiency, constant speed of driving mechanism, etc., to achieve convenient movement and rotation field, low maintenance cost and low failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

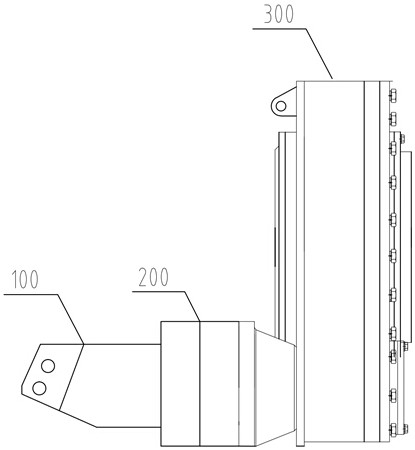

[0054] as attached figure 1 As shown, a drill power head assembly provided for an embodiment of the present invention includes:

[0055] Drill pipe drive reduction box 300, used to install the drill pipe 400 for drilling the coal seam;

[0056] Planetary reducer 200; the drill pipe driving reducer 300 is installed on the planetary reducer 200, and is connected with the planetary reducer 200 in transmission;

[0057] The variable hydraulic motor 100 is used to provide power to the planetary reducer 200 so that the drill rod 400 installed on the drill rod drive reducer 300 can achieve multi-speed or stepless speed change.

[0058] The working principle of the embodiment of the present invention is as follows:

[0059]The variable hydraulic motor 100 drives the planetary reducer 200 to run, and the planetary reducer 200 drives the drill rod drive reducer 300 to run. The power output end of the drill rod drive reducer 300 is used to install the drill rod 400 for drilling the coa...

Embodiment 2

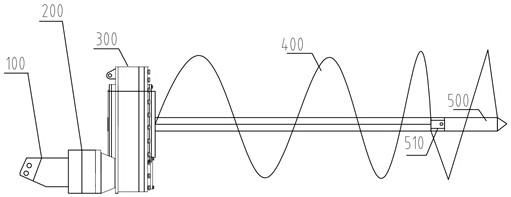

[0066] as attached figure 2 As shown, one embodiment of the present invention also provides a drill power drill bit, comprising:

[0067] drill bit 500;

[0068] Drill rod 400; the drill bit 500 is arranged at one end of the drill rod 400;

[0069] The drill head assembly in Embodiment 1; the drill rod 400 is installed on the drill rod driving reduction box 300 of the drill head assembly.

[0070] as attached figure 2 As shown, as a preferred embodiment of the present invention, the drill bit 500 and the drill rod 400 are both helical.

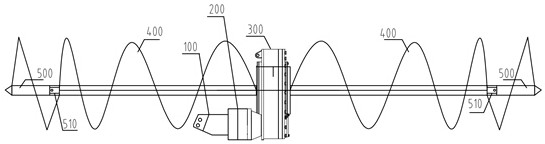

[0071] as attached image 3 As shown, as a preferred embodiment of the present invention, the drill bit 500 and the drill rod 400 are provided with two parts, and the drill rod drive reduction box 300 has two power output ends; the two drill bits 500 are respectively arranged on two One end of the drill rod 400, and the two drill rods 400 are respectively installed on the two power input and output ends of the drill rod drive reduction ...

Embodiment 3

[0076] as attached Figure 4 As shown, an embodiment of the present invention also provides a kind of auger drilling machine, comprising:

[0077] The drilling rig power drill described in any one of embodiment 2;

[0078] Frame assembly 700; the power drill bit of the drilling rig is movably arranged on the frame assembly 700;

[0079] Base 800; the frame assembly 700 is movably arranged on the base 800;

[0080] The angle adjusting member 900 is arranged between the frame assembly 700 and the base 800 , and is used to drive the frame assembly 700 to deflect on the base 800 .

[0081] Specifically, the auger drilling machine provided in this embodiment has all the advantages of the drill power head assembly in embodiment 1 and the power drill bit in embodiment 2. In addition, since the angle adjustment member 900 is provided between the base 800 and the frame assembly 700 of this embodiment, the power bit of the drilling rig located on the frame assembly 700 can achieve a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com