Underground compressed block stacking type filling system and method

A technology of compressing blocks and blocks, which is applied in the direction of filling, earth square drilling, safety devices, etc., can solve the problems of low density of filling body and loose state of filling materials in goafs, achieve good economical and applicable effects, and reduce gas The effect of gathering and improving the density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

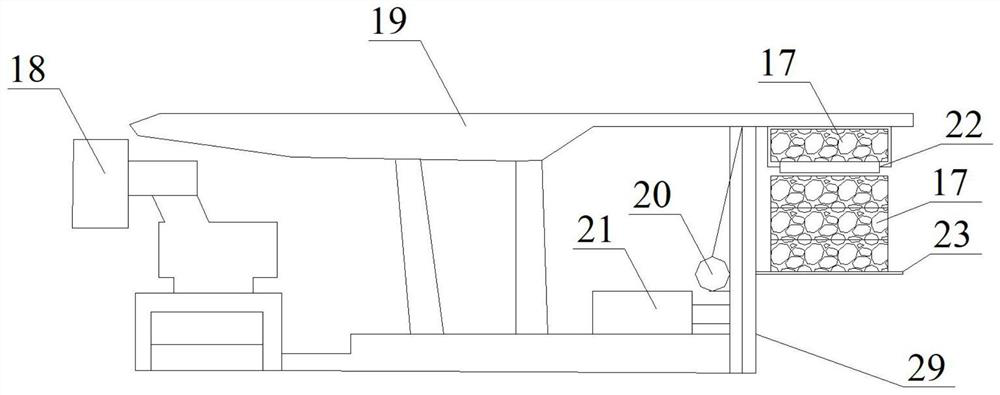

[0028] see image 3 and Figure 4 , the compression block filling system is mainly a special push-in block type filling support. The front part of the support is basically the same as the front part of the conventional support. They are all composed of shearer 18, hydraulic support 19, conveyor and other mechanisms. The rear part of the support is It is specially made for pushing into blocks, and mainly includes devices such as a horizontally telescopic push plate 24, a mobile platform 23, a conveyor 22 behind the frame, and a mobile platform lifting column 29. The composition and parameters of the conveyor 22 behind the frame are basically the same as those of the aforementioned filling and compression block conveyor, suspended on the back and upper side of the hydraulic support 19, connected with the top beam of the hydraulic support 19, and the height from the top beam is in the range of 35-45cm to ensure the filling and compression The blocks 17 can smoothly pass through ...

Embodiment 2

[0030] The specific filling method is as follows:

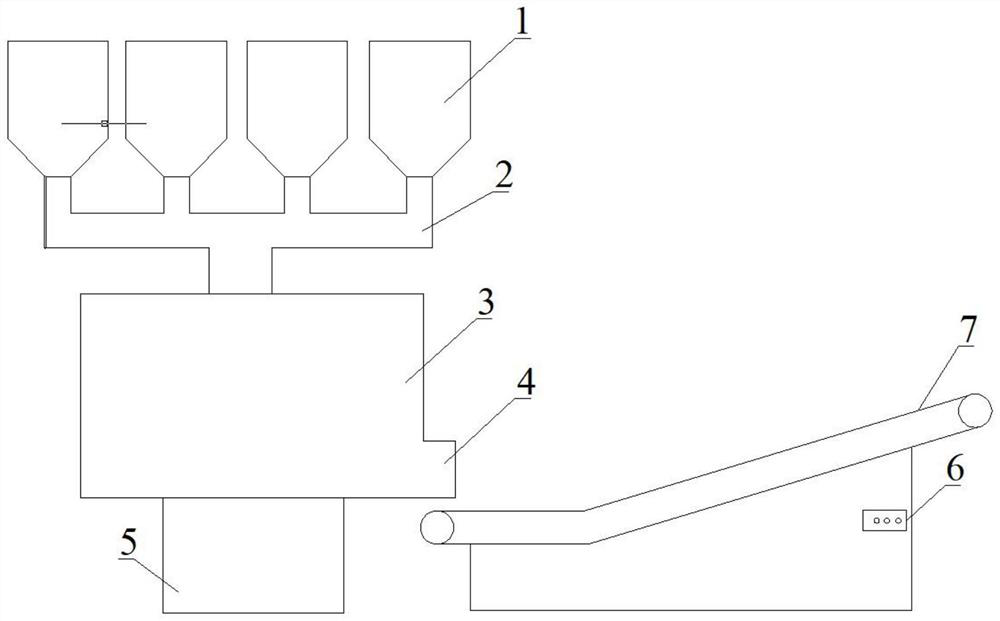

[0031] Process 1: Put the filling material 16 in each material storage bin 1 into the material mixing tank 3 according to a certain ratio, add a certain amount of water, start the mixer 5 to fully stir the mixed material, and the mixed filling material 16 passes through the belt The machine 7 is transferred to the filling material 16 compression molding system. The filling material 16 in the material mixing barrel should be continuously in a stirring state, and the filling material 16 in the mixing barrel 3 should not be less than 1 / 3 of the barrel volume during the production process of the filling compressed block 17, so as to avoid affecting the follow-up work progress.

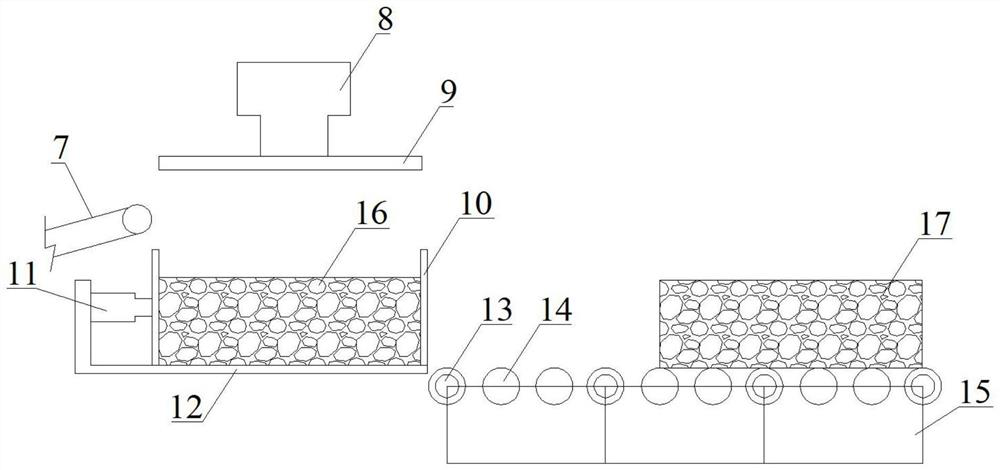

[0032] Process 2: adjust the size of the compression molding box 12, turn on the control switch 6 at the tail of the belt conveyor 7, put the filling material 16 into the compression molding box 12 where the bottom and surrounding steel plates are fixed, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com