Converter steelmaking endpoint intelligent control method

A converter steelmaking and intelligent control technology, applied in manufacturing converters, computer-aided design, design optimization/simulation, etc., can solve problems such as unfavorable one-button steelmaking, low modeling efficiency, and inconvenience in finding the optimal parameters of the model.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0090] The specific embodiments provided by the present invention will be described in detail below in conjunction with the accompanying drawings.

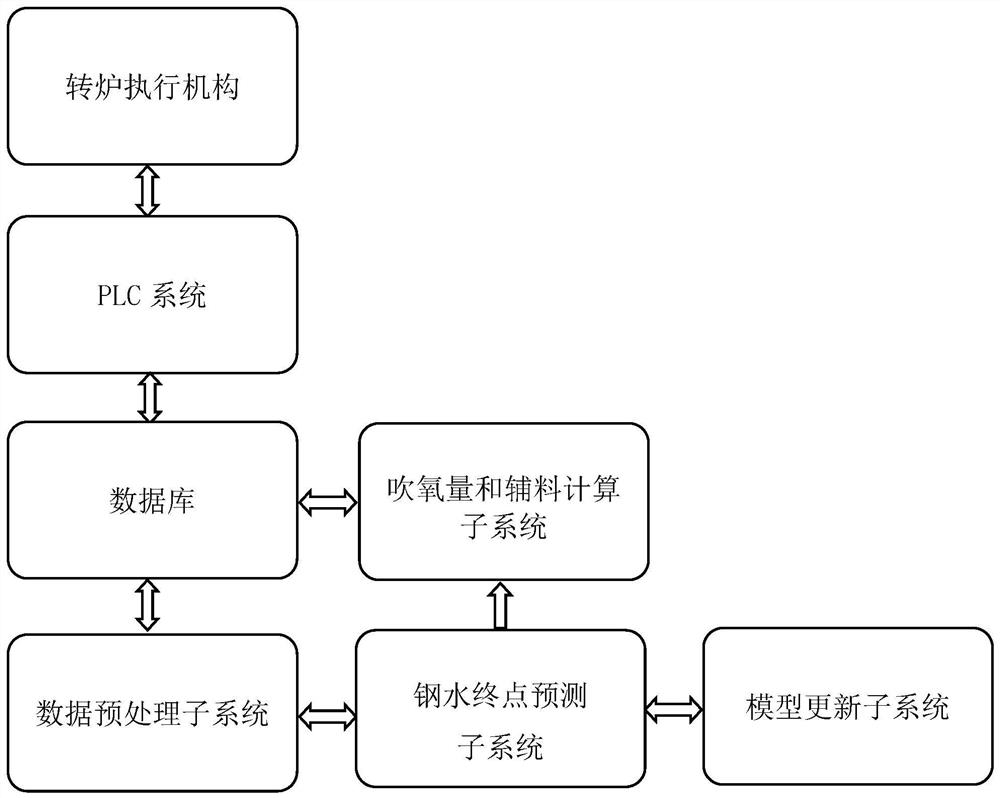

[0091] Such as figure 1 As shown, an intelligent control method for the end point of converter steelmaking, the control method is realized by the following subsystems: data preprocessing subsystem, molten steel end point prediction subsystem, oxygen blowing amount and auxiliary material calculation subsystem, and model update subsystem.

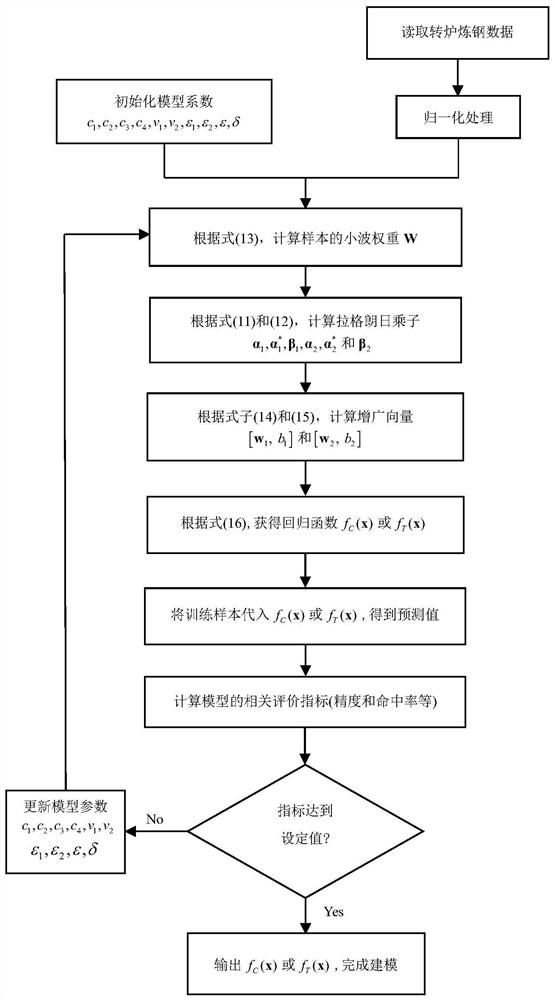

[0092] 1) Data preprocessing subsystem: collect data from the database, perform data preprocessing, and determine the input variables of the endpoint carbon content and temperature prediction subsystem model through independence and correlation analysis to ensure the accuracy of the model; specifically include the following steps :

[0093] Step 1-1: Read n sets of converter data from the database, preprocess them, and remove irrelevant information such as smelting number, shift, name of furnace...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com