Coating agent, modified graphite material, preparation method and application of modified graphite material, and lithium ion battery

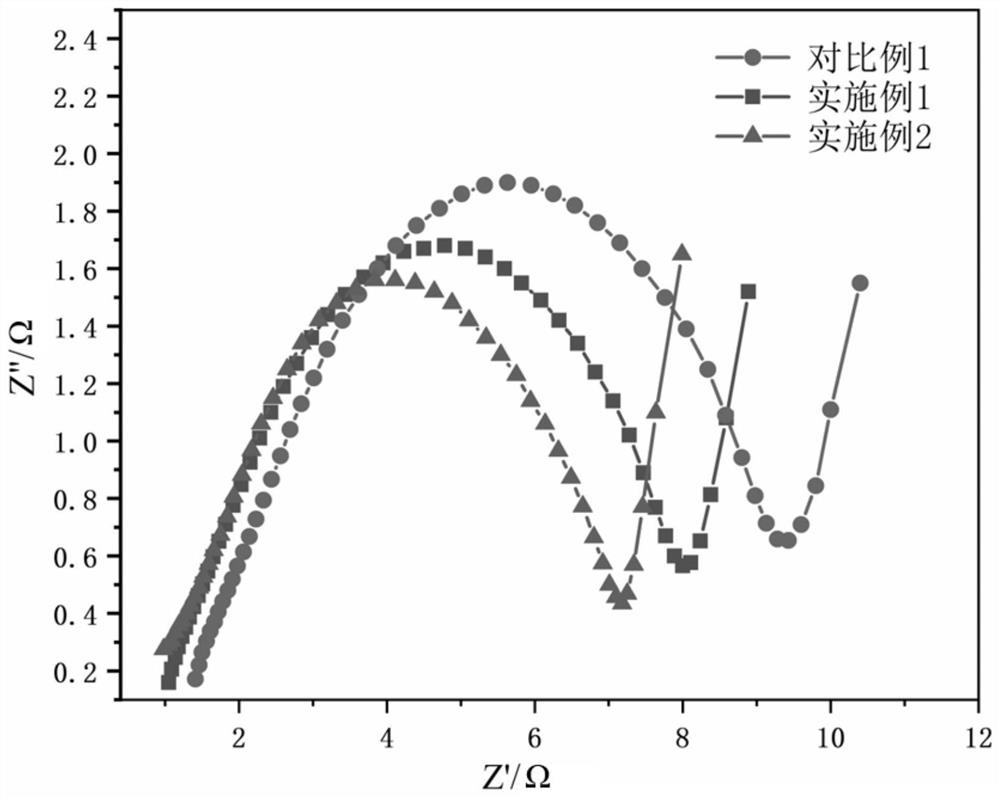

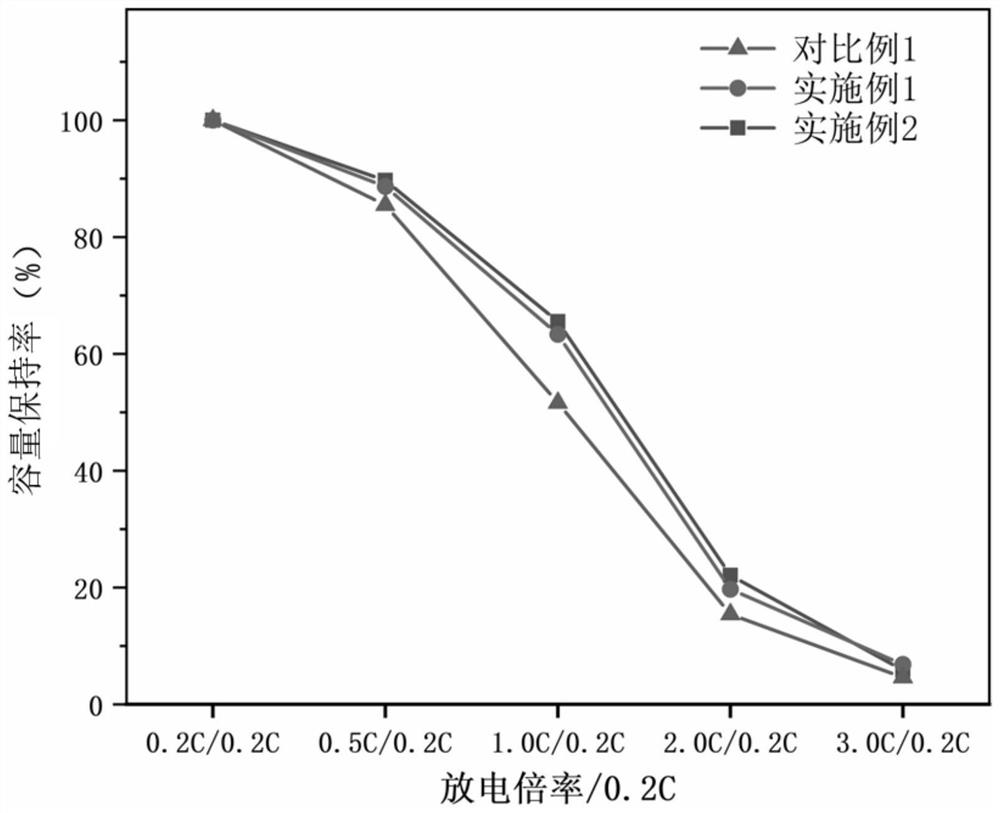

A lithium-ion battery and graphite material technology, applied in the field of coating agents, can solve the problems of uneven coating, poor rate performance and high impedance, and achieve the effects of uniform coating, reduced impedance and good rate performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

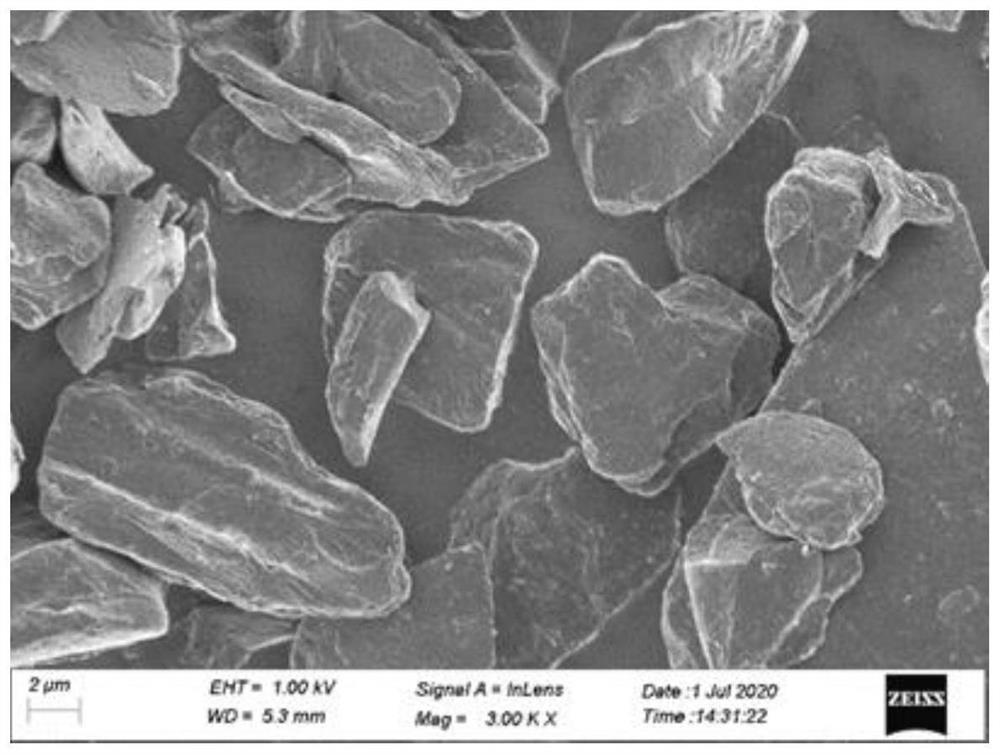

[0049](1) Preparation of artificial graphite: set the particle size as D50 to be 9.5um. The petroleum coke is heat-treated in a horizontal coating kettle at a heating temperature of 630°C for 8 hours, and the protective gas used is high-purity nitrogen to obtain a heat-treated graphite intermediate product; Graphitization treatment is carried out at a temperature of 3000°C for 35 hours in a graphitization furnace, and artificial graphite can be obtained after natural cooling.

[0050] (2) Preparation of coating agent: put coumarone resin and industrial washing oil with a mass ratio of 2:1 in a 5000mL three-neck flask, heat to 110°C, and stir at a speed of 80r / min at the same time, stirring The time is 1 hour to ensure that the two components are evenly dispersed. After cooling in the air, pour it out, and the formed mixed solution is the coating agent.

[0051] (3) Preparation of coated graphite material: the artificial graphite prepared in step (1) and the coating agent in s...

Embodiment 2

[0054] The difference from Example 1 is that the mass ratio of coumarone resin: washing oil is 3:1, and the remaining steps are all the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com