Method for producing thin-specification anti-seismic refractory steel by adopting continuous rolling and rolling heat preservation

A thin-gauge, coil-rolling technology, applied in metal rolling, temperature control, etc., can solve the problems of difficult production of anti-seismic refractory steel, difficult to guarantee high temperature performance, and technical reports of refractory steel, achieve good room temperature strength, reduce production and manufacturing Difficulty, the effect of excellent comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

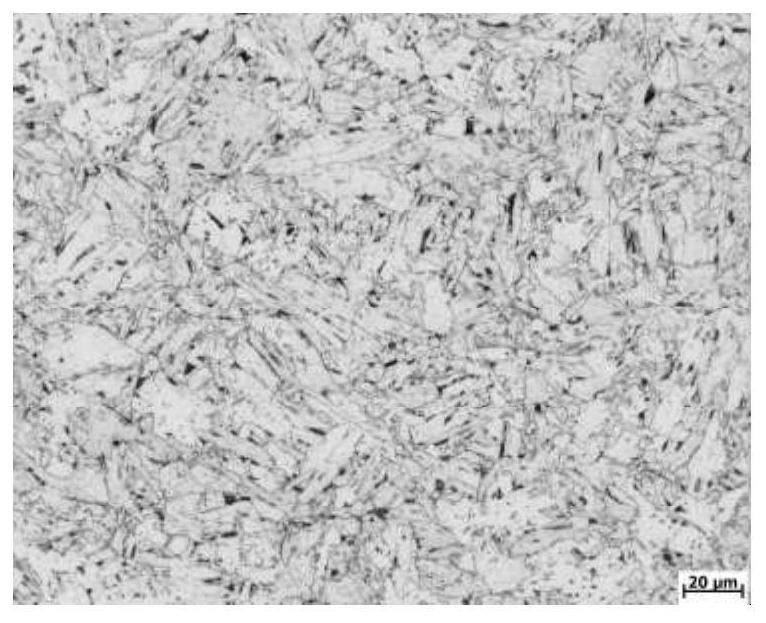

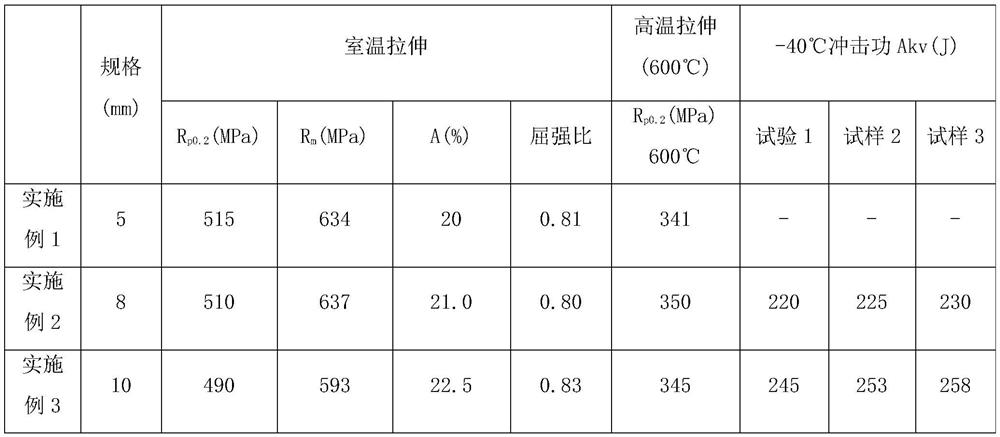

[0023] A method for producing thin gauge anti-seismic and refractory steel with a thickness of 5mm by continuous rolling and coil rolling heat preservation provided in this embodiment includes the following process steps:

[0024] Slab heating furnace heating process: the heating temperature is 1170°C, and the furnace time is 220min, and the fine and uniform original austenite structure is obtained inside the steel;

[0025] The billet rolling process of the plate rolling mill: the original billet is rolled into an intermediate billet with a thickness of 110mm and cooled naturally, and the intermediate billet is returned to the furnace for heating;

[0026] Intermediate billet reheating process: the heating temperature is 1251°C, and the furnace time is 110min;

[0027] The rolling process of the medium and thick plate rolling mill of the intermediate billet: the rolling method adopts continuous rolling, and at the same time adopts the method of coil rolling and heat preservat...

Embodiment 2

[0029] A method for producing thin gauge anti-seismic and refractory steel with a thickness of 8mm by continuous rolling and coil rolling heat preservation provided in this embodiment includes the following process steps:

[0030] Slab heating furnace heating process: the heating temperature is 1180°C, and the furnace time is 220min, and the fine and uniform original austenite structure is obtained inside the steel;

[0031] The billet rolling process of the thick plate rolling mill: the original billet is rolled into an intermediate billet with a thickness of 120mm and cooled naturally, and the intermediate billet is returned to the furnace for heating;

[0032] Blank reheating process: the heating temperature is 1235°C, and the time in the furnace is 120min;

[0033] The rolling process of the medium and thick plate rolling mill between the blanks: the rolling method adopts continuous rolling, and at the same time adopts the method of coil rolling heat preservation. After 9 ...

Embodiment 3

[0035] A method for producing thin gauge anti-seismic and refractory steel with a thickness of 10mm by continuous rolling and coil rolling heat preservation provided in this embodiment includes the following process steps:

[0036] Slab heating furnace heating process: the heating temperature is 1216°C, the furnace time is 220min, and the steel interior obtains a fine and uniform original austenite structure;

[0037] The billet rolling process of the medium and heavy plate rolling mill: the original billet is rolled into an intermediate billet with a thickness of 130mm and cooled naturally, and the intermediate billet is returned to the furnace for heating;

[0038] Intermediate billet reheating process: the heating temperature is 1250°C, and the furnace time is 130min;

[0039] The rolling process of the medium and thick plate rolling mill of the intermediate billet: the rolling method adopts continuous rolling, and at the same time adopts the method of coil rolling and heat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com