Movable noise reduction equipment for factory machining and noise reduction method

A kind of equipment and factory technology, which is applied in the field of movable noise reduction equipment for factory processing, can solve the problems of inconvenient observation of internal machine operation, chaotic pitch and sound intensity changes, and hearing damage of staff, so as to avoid sound pollution and ensure Cooling effect, easy-to-move effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

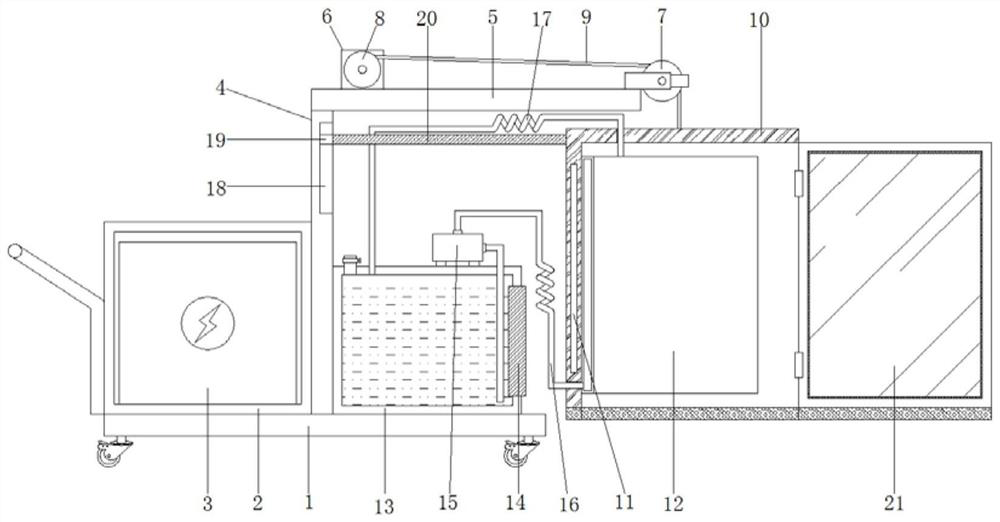

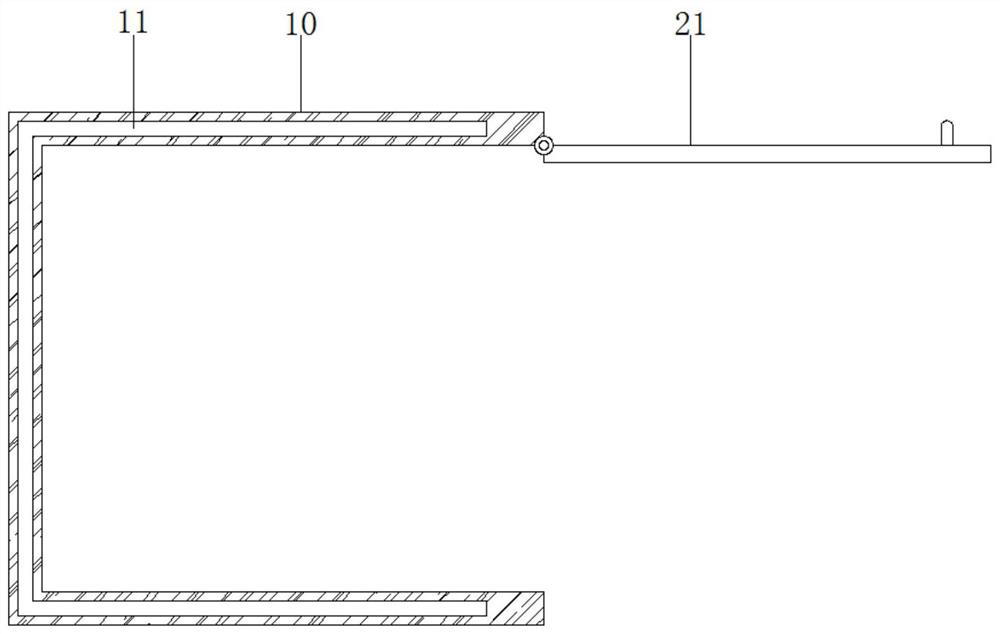

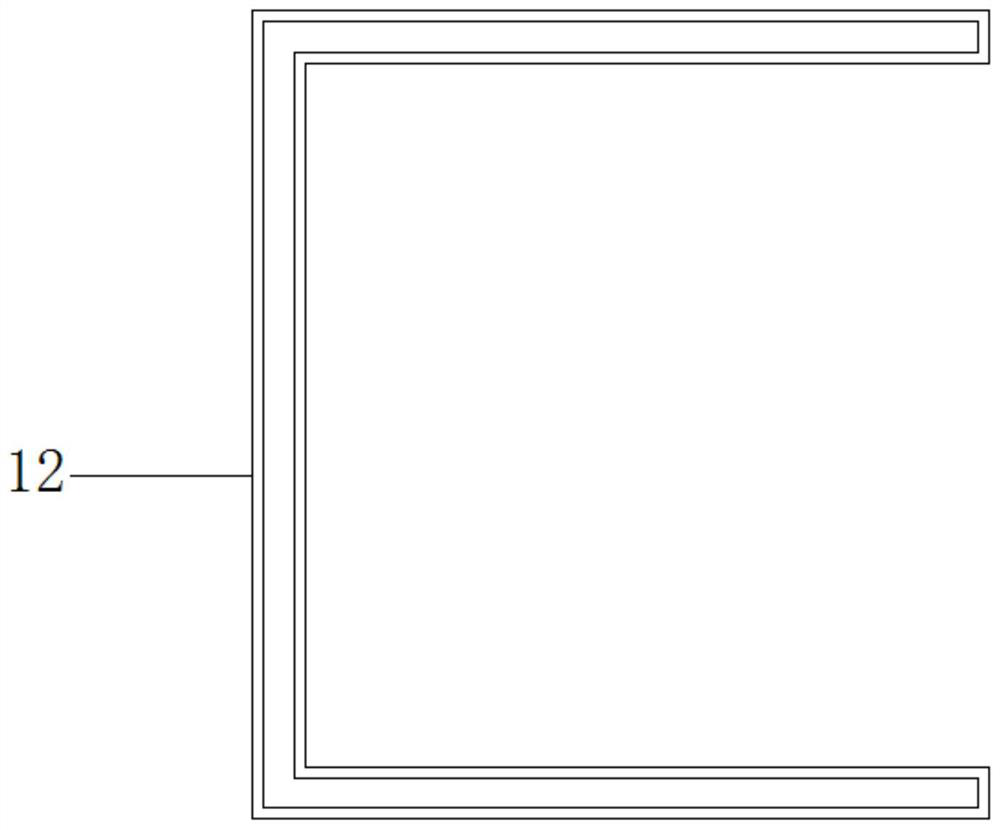

[0023] refer to Figure 1-4 , a mobile noise reduction device for factory processing, including a base plate 1 with brake wheels at the four corners of the bottom, through the brake wheels set at the four corners of the bottom of the base plate 1, the device as a whole is easy to move, easy to transfer, and has strong applicability. The sound insulation cover 10 can effectively isolate the noise generated by the operation of the machine from the outside world, and at the same time, the C-shaped cavity 11 is filled with sound insulation cotton, which further improves the sound insulation and noise reduction ability of the equipment, avoids the generation of sound pollu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com