Wheat grain lead control agent as well as preparation method and application method thereof

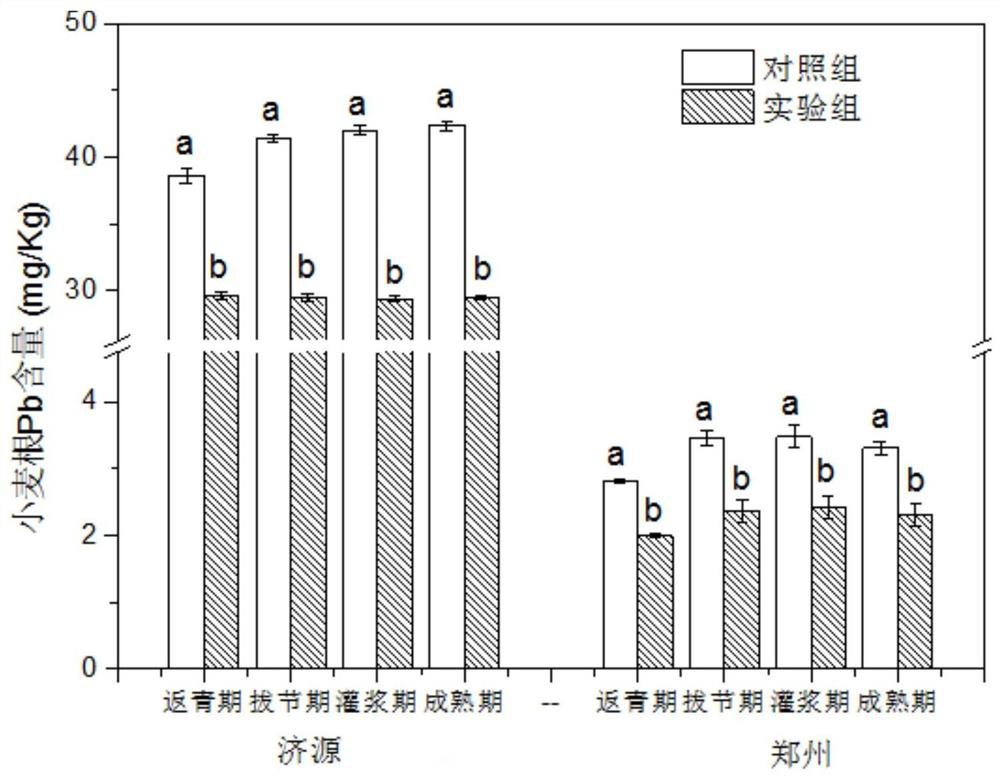

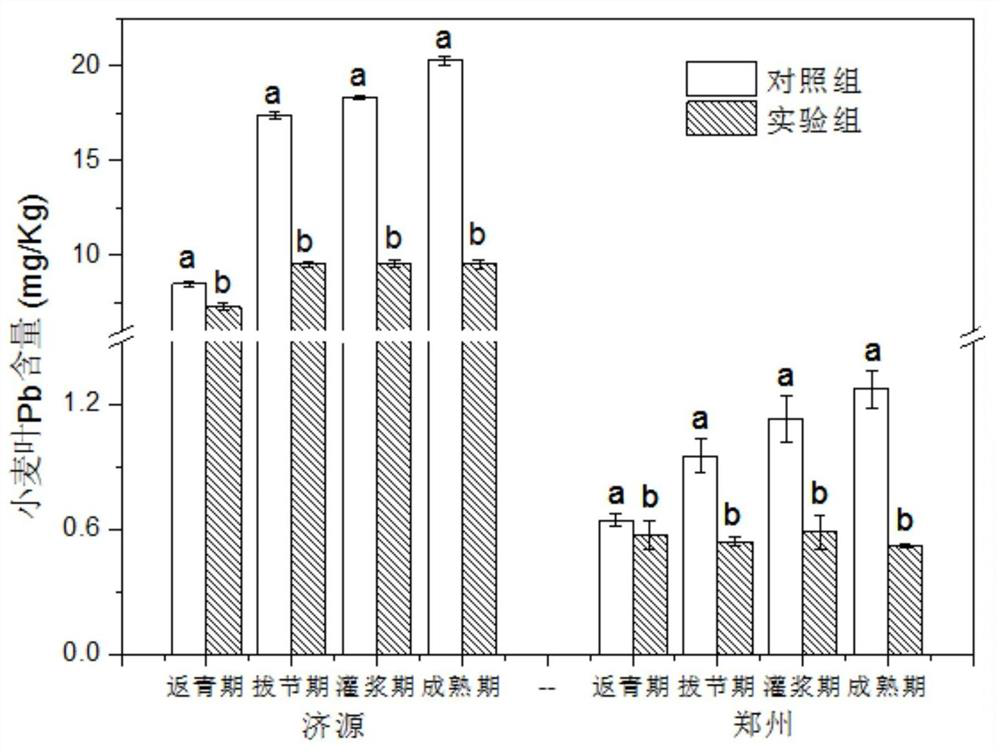

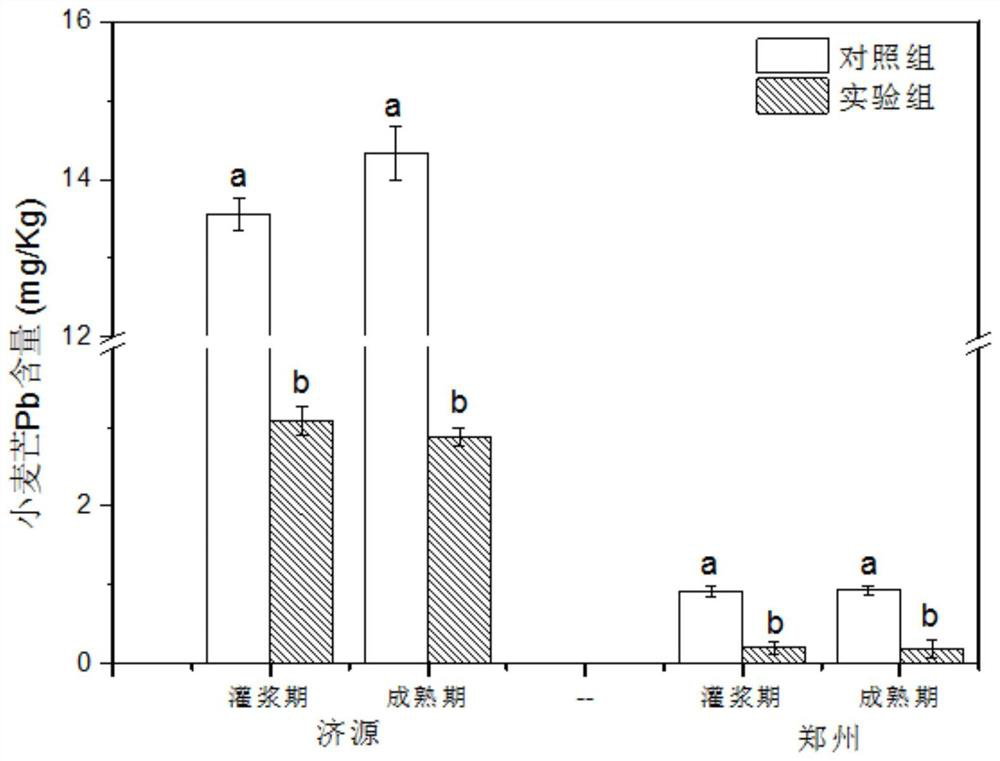

A technology of wheat grains and application methods, applied in the field of environmental pollution control, can solve the problems of lack of lead control technology in wheat grains, ignoring the contribution of lead content in atmospheric dust, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] This embodiment provides a wheat grain lead control agent for air-soil synergistic prevention and control, which includes three components A, B, and C, wherein the A agent is made of the following raw materials in mass percentages:

[0038] Calcium phosphate 6.5%, Fe 3 o 4 @C-COOH3.5%, nano-manganese sulfate 0.2%, nano-zinc sulfate 0.2%, nano-magnesium sulfate 0.2%, the balance is urea;

[0039] Agent B is made of the following raw materials in mass percentage: nano-magnesium sulfate 1%, humic acid 3%, Fe 3 o 4 @C-COOH0.5%, alkyl naphthalene sulfonate 1%, the balance is water;

[0040] Agent C is made from the following raw materials in mass percentage: 0.3% nano-manganese sulfate, 0.3% nano-zinc sulfate, 3% humic acid, Fe 3 o 4 @C-COOH 0.2%, alkyl naphthalene sulfonate 1%, balance water.

[0041] The preparation method of described lead control agent, wherein, the preparation method of A agent comprises the following steps:

[0042] S1: Weigh the raw materials i...

Embodiment 2

[0055] Raw material and operation in the present embodiment are all identical with embodiment 1, difference is:

[0056] The content of urea in Agent A is 88.1%, the content of calcium phosphate is 7%, the content of Fe3O4@C-COOH is 4%, the content of nano manganese sulfate is 0.3%, the content of nano zinc sulfate is 0.3%, and the content of nano magnesium sulfate is 0.3%;

[0057] The content of nano-magnesium sulfate in Agent B is 0.5%, the content of humic acid is 2%, and the content of alkylnaphthalene sulfonate is 0.5%; the interval between each spraying is 19 days;

[0058] The content of nano-manganese sulfate in agent C is 0.2%, the content of nano-zinc sulfate is 0.2%, the content of humic acid is 2%, Fe 3 o 4 The content of @C-COOH is 0.1%, the content of alkyl naphthalene sulfonate is 0.5%, and the interval between each spraying is 7 days.

Embodiment 3

[0060] Raw material and operation in the present embodiment are all identical with embodiment 1, difference is:

[0061] The content of urea in Agent A is 90.7%, the content of calcium phosphate is 6%, Fe 3 o 4 The content of @C-COOH is 3%, the content of nano-manganese sulfate is 0.1%, the content of nano-zinc sulfate is 0.1%, and the content of nano-magnesium sulfate is 0.1%;

[0062] The content of nano-magnesium sulfate in agent B is 1.5%, the content of humic acid is 4%, and the content of Fe 3 o 4 The content of @C-COOH is 1%, the content of alkyl naphthalene sulfonate is 1.5%, and the interval between each spraying is 21 days;

[0063] In agent C, the content of nano manganese sulfate is 0.4%, the content of nano zinc sulfate is 0.4%, the content of humic acid is 4%, Fe 3 o 4 The content of @C-COOH is 0.3%, the content of alkyl naphthalene sulfonate is 1.5%, and the interval between each spraying is 5 days.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com