A kind of conductive microcapsule and graphene conductive ink and its preparation method and application, graphene conductive film and self-healing method thereof

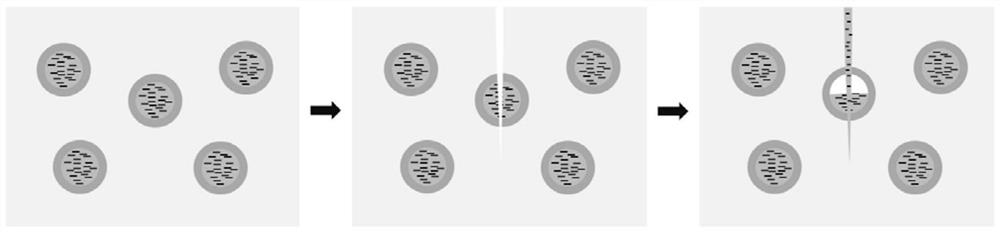

A technology of conductive ink and graphene, which is applied in microcapsule preparation, microsphere preparation, ink and other directions, can solve the problems of short service life and decreased electrical performance of conductive film, and achieves extended service life, not easy to decline in electrical performance, good performance The effect of conductive self-healing function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] (1) Preparation of conductive microcapsules

[0039] S1. Mix 0.1 part of graphene with 1.5 parts of low-melting polyurethane pellets (melting point 50-60°C, the same below), feed them into an internal mixer and melt blend for 5 hours at 80°C to obtain graphene and low-melting point Composite materials of polyurethane;

[0040] S2. Add 1 part of melamine, 2 parts of formaldehyde and 20 parts of water into the reaction vessel, adjust the pH value of the solution to 8-9 with triethanolamine, and stir at 600r / min at a constant temperature of 70°C until the solution is transparent Obtain prepolymer solution;

[0041] S3. Add the composite material of graphene and low-melting polyurethane in step S1 and 0.1 part of PE-6200 into the reaction vessel, stir at a constant temperature of 70°C for 0.5h, then add 40 parts of water, and use an emulsifier at 15,000r / Stir and emulsify at min speed for 10 minutes to obtain a stable oil-in-water emulsion;

[0042] S4. Use acetic acid ...

Embodiment 2

[0047] (1) Preparation of conductive microcapsules: same as in Example 1.

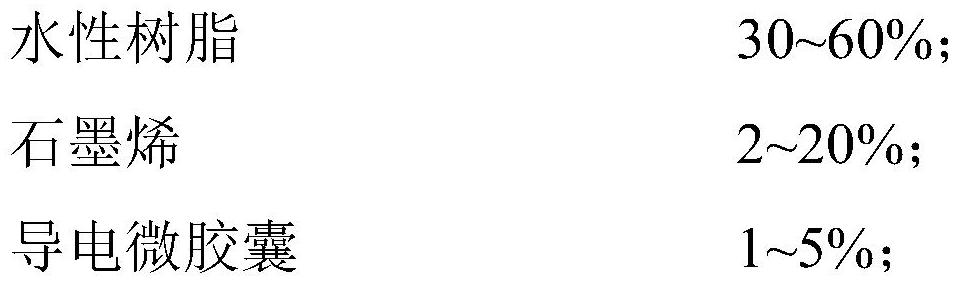

[0048] (2) Preparation of graphene conductive ink: Add 2 parts of dispersant, 5 parts of graphene, and 0.3 part of defoamer to 48.7 parts of water in turn, mix and wet grind for 2 hours with a nano-sand mill to prepare a uniform graphene slurry The obtained graphene slurry and 3 parts of conductive microcapsules were sequentially added to 40 parts of water-based polyurethane resin, stirred and blended at a low speed of 600r / min for 10min, and then 1 part of thickener was added to adjust the viscosity of the system to 10,000-50,000cP. Filtration discharge obtains graphene conductive ink.

Embodiment 3

[0050] (1) Preparation of conductive microcapsules: same as in Example 1.

[0051] (2) Preparation of graphene conductive ink: Add 2 parts of dispersant, 5 parts of graphene, and 0.3 part of defoamer to 46.7 parts of water in turn and mix them with a nano-sand mill for 2 hours to prepare a uniform graphene slurry The obtained graphene slurry and 5 parts of conductive microcapsules were sequentially added to 40 parts of water-based polyurethane resin, stirred and blended at a low speed of 600r / min for 10min, and then 1 part of thickener was added to adjust the viscosity of the system to 10,000-50,000cP. Filtration discharge obtains graphene conductive ink.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com