A kind of rotor guide bar and preparation method thereof

A rotor guide bar and formula technology, applied in the field of materials, can solve the problems of cumbersome preparation methods and low production efficiency, and achieve the effect of simple process and uniform grain size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

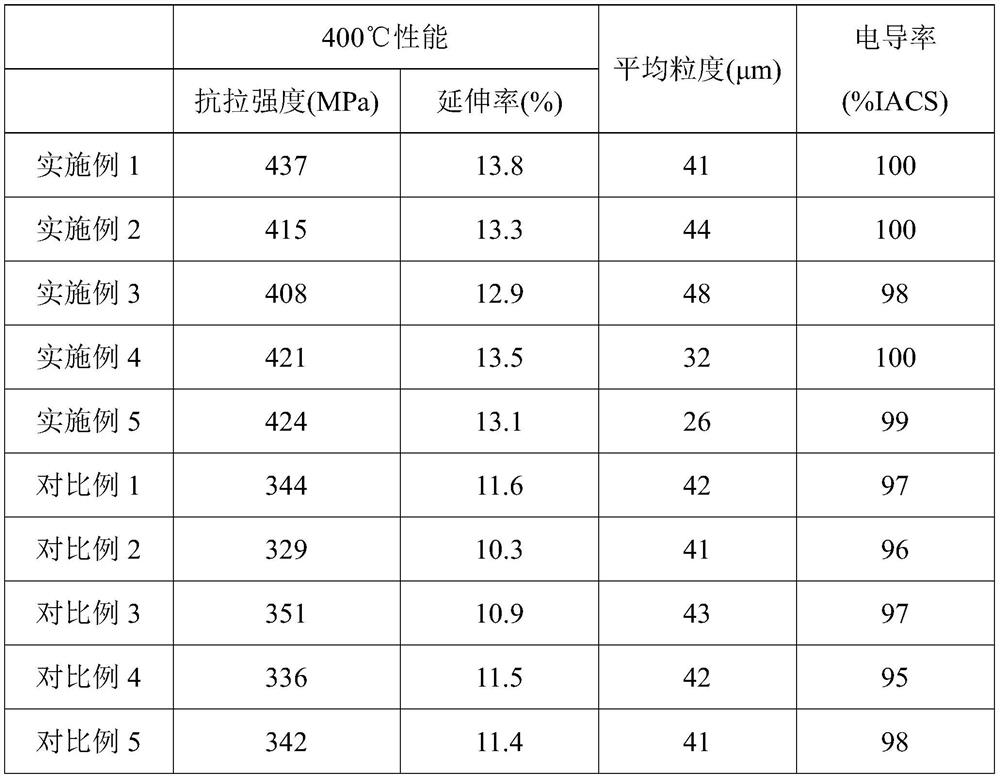

Examples

Embodiment 1

[0049] This embodiment provides a method for preparing a rotor conductor, and the method includes the following steps:

[0050] In terms of mass percentage, the rotor bar includes: Zr 0.09wt%, Ni 0.2wt%, Co 0.2wt%, Mg0.35wt%, Si 1.5wt%, Al 0.3wt% and Ag 0.06wt%, the balance is Copper and unavoidable impurities; among the unavoidable impurities, Fe≤0.05wt% and Pb≤0.05wt%.

[0051] (1) ball milling and mixing zirconium powder, magnesium powder, silicon powder, aluminum powder, silver powder, copper plate and binder according to the formula amount, and use absolute ethanol to immerse the abrasive during ball milling to obtain the first abrasive with an average particle size of 30 μm; The binding agent is an epoxy resin, and the addition amount of the binding agent is 11wt% of the first grinding material;

[0052] (2) Heat treating the first grinding material obtained in step (1) at 700° C. to remove the binder in the first grinding material, and obtain the second grinding materi...

Embodiment 2

[0056] This embodiment provides a method for preparing a rotor conductor, and the method includes the following steps:

[0057] In terms of mass percentage, the rotor bar includes: Zr 0.09wt%, Ni 0.15wt%, Co 0.25wt%, Mg 0.32wt%, Si 1.2wt%, Al 0.35wt% and Ag 0.07wt%, the balance is Copper and unavoidable impurities; among the unavoidable impurities, Fe≤0.05wt% and Pb≤0.05wt%.

[0058] (1) ball milling and mixing zirconium powder, magnesium powder, silicon powder, aluminum powder, silver powder, copper plate and binder according to the formula amount, use absolute ethanol to immerse the abrasive during ball milling to obtain the first abrasive with an average particle size of 35 μm; The binding agent is a phenolic resin, and the addition amount of the binding agent is 11.5wt% of the first grinding material;

[0059] (2) heat treating the first grinding material obtained in step (1) at 750° C. to remove the binder in the first grinding material, and obtain the second grinding ma...

Embodiment 3

[0063] This embodiment provides a method for preparing a rotor conductor, and the method includes the following steps:

[0064] In terms of mass percentage, the rotor bar includes: Zr 0.08wt%, Ni 0.1wt%, Co 0.3wt%, Mg0.3wt%, Si 1wt%, Al 0.4wt% and Ag 0.06wt%, the balance is copper and unavoidable impurities; among the unavoidable impurities, Fe≤0.05wt% and Pb≤0.05wt%.

[0065] (1) ball milling and mixing zirconium powder, magnesium powder, silicon powder, aluminum powder, silver powder, copper plate and binder according to the formula amount, use absolute ethanol to immerse the abrasive during ball milling to obtain the first abrasive with an average particle size of 40 μm; The binding agent is a phenolic resin, and the addition amount of the binding agent is 12wt% of the first grinding material;

[0066] (2) Heat treating the first grinding material obtained in step (1) at 800° C. to remove the binder in the first grinding material, and obtain the second grinding material af...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com